Digital printers have come a long way. From the first black and white compact digital printer mass-produced in the ‘60s, we now have printers that are capable of printing photo-realistic images on flat and curved surfaces alike.

These come in the form of ultraviolet (UV), Direct to Film (DTF), and UV DTF printers, which are widely considered the industry standard today. However, the market is already too saturated with different types of printers. So, what sets these three apart? And how are they different from each other?

This article will answer all your questions, covering everything you need to know about UV, DTF, and UV DTF printers, and helping you determine which one you need for your business.

A brief history of UV, DTF, and UV DTF printers

The standards for commercial printers have risen significantly over the last few decades. Traditional printers can no longer satisfy the needs of most customers today, including rapid processing and printing on hard surfaces. To meet these needs and fill the gaps of traditional printers, ultraviolet (UV) printing was invented.

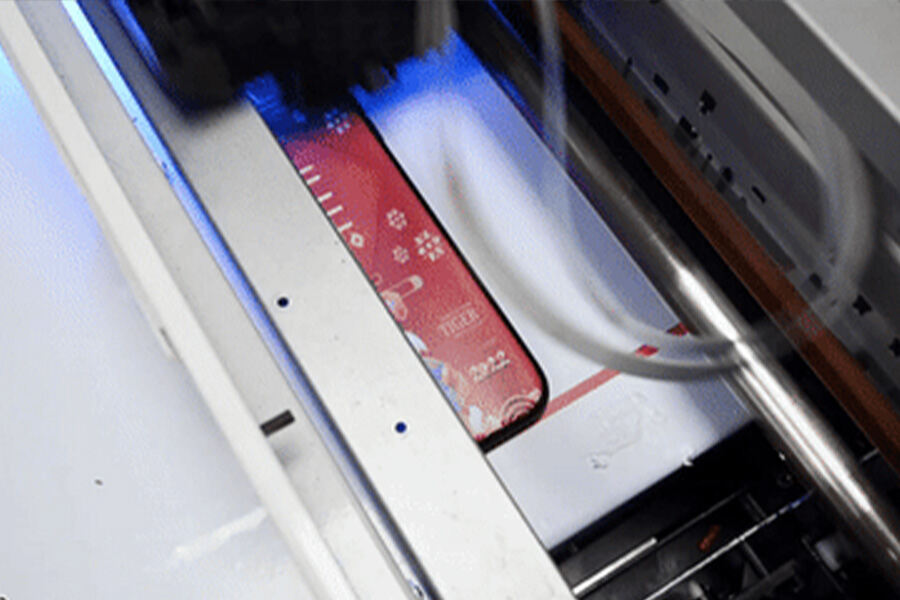

UV printing uses special inks that dry almost instantaneously when exposed to UV light. In a UV printer, the substrate (in most cases, paper) passes through the printer and receives wet ink. Then, the substrate is immediately exposed to UV light, causing the ink to dry. There is zero chance of ink leakage or diffusion in the entire process. As a result, the details of the printed image and text are crisp and clear.

UV printers sped up and simplified the printing process, which ultimately allowed businesses to meet the increasing demand for their products. At the same time, UV printers introduced textured effects that cannot be created by traditional printers. From pens to smartphone cases and USB sticks, UV printers were able to create vibrant colors and outstanding gloss, matt, textured, and 3D effects on a wide range of materials.

Although UV printers were able to meet the changing demands of customers, they still had shortcomings. For example, if the surface of an object is uneven or sloped, UV printers have difficulty printing a design accurately.

To solve these problems, printer manufacturers created DTF printers. Unlike UV printers, DTF printers allow you to print on a polyester (PET) film first instead of printing directly on the surface of an object.

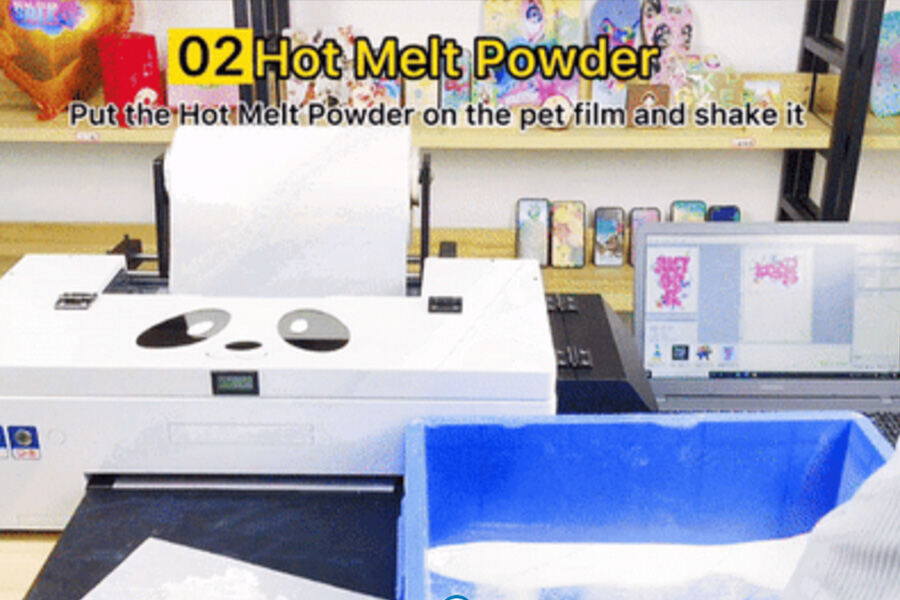

After you print your design on a PET film, you need to powder the film with adhesive and press the film on a heat press. After pre-treating the film, you can transfer your design from the film to an object by using the heat press. This allows you to print designs on objects that have an uneven or irregular surface. DTF printers excel at and are commonly used for printing on textile and leather.

However, DTF printers have their shortcomings too. Compared with the prints created by UV printers, the prints created by DTF printers lacked vibrancy. And although DTF printers produced excellent prints on textile and leather materials, UV printers still worked better on a wider range of substrates.

Thus, printer manufacturers needed to create a printer that had the strengths of both UV printers and DTF printers. This resulted in UV DTF printers.

A UV DTF printer uses UV ink and UV exposure to initially print a design onto a PET film (called A Film). Then, you need to use a laminator to print the design of A Film to a second PET film (B Film). After that, you simply need to use your fingers to press the laminated PET film on the object for a second, then tear off the film as you would with a sticker. No heat-pressing is required. This way, UV DTF printing works on almost all surfaces and can print out vibrant and high-quality images accurately.

UV printers vs. UV DTF printers

Similarities: UV printers and UV DTF printers both utilize UV heating technology and UV ink. Thus, both printers can produce prints of about the same high level of quality.

Differences: UV printers print directly on the surface of an object. If the object has a sloped surface, the UV printer might not produce satisfactory results.

On the other hand, UV DTF printers allow you to print the design on a PET film first. This allows you to print designs on almost all types of materials and surfaces, unlike UV printers.

UV DTF printers vs. DTF printers

Similarities: DTF and UV DTF printers both require you to print the design on a PET film first and then transfer the design to the object.

Differences: The ink used by UV DTF printers is different from that used by DTF printers. UV DTF printers use UV ink, while DTF printers use DTF ink.

Although they both require you to transfer the design from a film to an object, the transferring processes are different. As mentioned, UV DTF printing requires you to laminate the film with a separate laminating machine. After that, you simply need to press the film with your fingers and tear off the cover of the film to finish the transfer. Unlike using a DTF printer, you do not need to pre-heat the film. This can save you hours during large operations.

On the other hand, DTF printers require adhesive powder and heat-pressing (not to mention, a heat press machine) for you to transfer your design to an object.

In addition, DTF printers produce the best results only for textile and leather, while UV DTF printers are more suitable for most other materials.

Main applications of UV, DTF, and UV DTF printers

Applications of UV printers:

- Advertisement materials, including labels and packaging, posters, signage, bottle printing, etc.

- Customized products, including leather printing, phone cases, glass, and metal materials.

- Home decoration, including printing on tile walls, glass sliding doors, wardrobes, and furniture by using vertical UV printers.

Applications of DTF printers:

- Apparel, including cotton, polyester, synthetic, silk, and cotton and poly blends.

- Produces best results for textile and leather.

Applications of UV DTF printers:

- Almost all applications of UV printers and DTF printers.

Comparison of UV, DTF, and UV DTF printers

Specifications

| Printers | UV printer (e.g. A5 UV printer) |

DTF printer (e.g. A3 DTF transfer printer) |

UV DTF printer (e.g. A3 UV DTF laminating printer) |

| Printing media | Phone case, leather, lithograph, crystal, acrylic, card, CD, U disk, and nameplate |

Leather, textile, etc. | Phone case, leather, lithograph, crystal, acrylic, card, CD, U disk, nameplate, textile, etc. |

| Required consumables | UV ink | Hot melt adhesive powder, DTF ink, and PET film | UV ink, AB film, and glue |

| Printing steps | 1. Use software to prepare the design 2. Place the item on a platform 3. Print the design on the item 4. Wait for printing to finish |

1. Use software to prepare the design 2. Print the design on a PET film 3. Powder the PET film 4. Dry the PET film with a heat press 5. Heat-press the PET film onto the material 6. Tear off the PET film |

1. Install films A and B 2. Use software to prepare the design 3. Print and laminate the design on films 4. Transfer the laminated film to the item |

| Ink needed | UV ink | DTF ink | UV ink |

| Price | About $2299 to $2699 | About $1799 | About $5899 to $5989 |

Pros and cons of UV, DTF, and UV DTF printers

UV printers:

Pros:

- Suitable for a wide range of materials and surfaces.

- Excellent image clarity, accuracy, and color saturation.

- No ink absorption and minimal chemical interaction with the object, creating prints that are smooth to the touch.

- Environmentally friendly with minimal volatile organic compounds (VOCs) released.

- Durable, flexible, and scratch-resistant prints.

- Efficient workflow, with minimal handling required.

Cons:

- UV ink can cause skin irritation, and therefore requires delicate handling.

- UV ink will not dry and cure without enough exposure to UV light. This problem commonly occurs in cheap or defective UV printers.

- UV ink is expensive.

- Printing on sloped surfaces may create unsatisfactory results.

DTF printers:

Pros:

- Suitable for almost all types of fabrics.

- Minimal pretreatment required, compared to Direct to Garment (DTG) printing.

- Faster and more efficient than DTG printing.

- Excellent light, oxidation, and water resistance on prints.

Cons:

- Unable to print images of the same color quality and vibrance as UV printers.

- Printed pattern is less smooth than that created by UV printing.

UV DTF printers:

Pros:

- Able to print on almost all materials and surfaces.

- Easy to operate, with no heat-pressing required on the material.

- Supports varnished prints.

- Provides almost all the advantages provided by UV and DTF printers.

Cons:

- Requires both UV ink and PET films (A and B Films).

- Requires laminating on a separate machine.

- Requires delicate handling for UV ink.

- Costs more on average compared to UV and DTF printers.

Future trends

Various types of printers and tools have been invented to satisfy the stringent requirements of niche markets. This makes printers more concentrated for certain fields, but also limits the functions of each type of printer.

As much as UV DTF printers are excellent at providing the benefits of both UV and DTF printers, users of UV DTF printers still need to perform laminating on a separate machine. This causes hiccups in the entire workflow process.

With that said, all printers and printing processes have their shortcomings. There is currently a demand for an all-in-one printer that can provide all the benefits of both UV and DTF printers without the downside of needing a separate laminating machine. This demand is not exclusive to the two types of printers, too. Uniting the functions of different types of printers will be the next trend in this industry.

Source from Procolored