There have been three revolutions in the past: production, steam, and water power; mass production by using electricity; and digital process, i.e., electronics, IT, and automation. Now, the Fourth Industrial Revolution is beginning. This revolution focuses extensively on combining the physical, digital and biological worlds. All this computation is now readily available and accessible in real-time to manufacturing industries. This is Industry 4.0.

Table of Contents

What is Industry 4.0?

Evolution of industry from 1.0 to 4.0

Industry 4.0 technological concepts

Characteristics of a smart factory

Advantages of Industry 4.0

Challenges of Industry 4.0

Final thoughts

What is Industry 4.0?

The Fourth Industrial Revolution, 4I or Industry 4.0, is a new phase of the Industrial Revolution that focuses on real-time data, interconnectivity, automation, and machine learning. It is associated with cyber-physical systems and intelligent digital technology to create a better-connected system that companies can focus on to better their production and stock control systems. Ideally, Industry 4.0 focuses on uniting a company’s processes, staff, and products.

It joins artificial intelligence, robotics, the internet of things, genetic engineering, quantum computing, and more. In people’s daily life, Industry 4.0 is slowly becoming increasingly important. Siri, GPS systems, Netflix recommendations, etc., are examples of Industry 4.0.

Evolution of industry from 1.0 to 4.0

The Industrial Revolution began in the 1800s and, over the years, has developed from the First Industrial Revolution to the Fourth Industrial Revolution.

The First Industrial Revolution

This Industrial Revolution happened between the 1700s and 1800s. In this period, manufacturing changed from manual labor to labor by people with the help of animals and to labor with the use of water and steam engines and different machine tools. It changed rural, agrarian villages into urban towns.

The Second Industrial Revolution

The Second Industrial Revolution took place in the early 20th century. The world entered this Industrial Revolution through the discovery of electricity. Steel and electricity helped manufacturers increase their efficiency by making their machines mobile. This period brought about the production of cost-effective steel, as well as the building of railroads and industrial engines.

The Third Industrial Revolution

The Third Industrial Revolution began in the late 1950s when companies began incorporating electrical and computer technology into their factories. This brought about a shift from analog to digital technology. Some technologies that drove the Third Industrial Revolution include robotics, 3D printing, artificial intelligence, as well as nano, bio, and IT technologies.

Industry 4.0 technological concepts

These technologies include the internet of things, analytics, machine learning, and artificial intelligence.

Industrial internet of things (IIoT)

The IIoT involves using the IoT in production processes. This helps companies to have better control of their operations. It encompasses applications such as robotics, medical services, and software-designed production processes. The data created from this can be used to optimize production.

Automation

Every company has one goal: to maximize production to maximize profits. Automation is a perfect way to achieve this goal. The use of equipment will make processes and systems in an organization automatic. Automation is achieved by the use of robotics and artificial intelligence and reduces the use of human effort.

Artificial intelligence (AI)

AI is the perceiving, synthesizing, and interpreting of human intelligence information by machines. It involves speech recognition, machine vision, natural language recognition, etc. AI can get data from a factory, synthesize and reprogram it, and apply it to optimize production.

Big Data and analytics

Big Data is a collection of information within an organization that can be used as a source to be analyzed. Industry 4.0 makes it easier to collect the data, analyze it, and offer a reasonable analysis that will change how the organization works.

Cyber-physical systems

Cyber-physical systems are a combination of computation, networking, and physical processes that offer feedback which the system gets and uses software to interpret and bring about results.

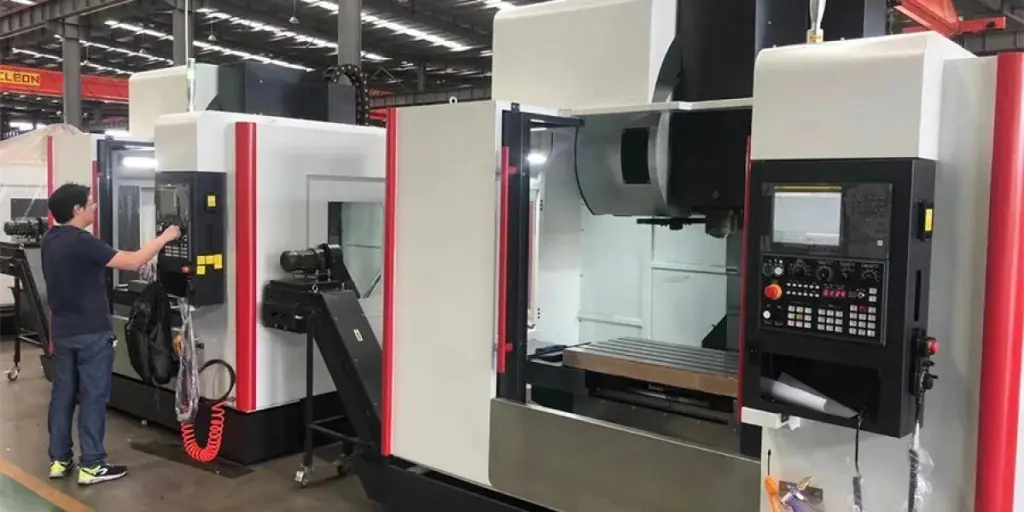

Smart factories

A smart factory is an effortless production connection from the planning stage to the actual production process. Industry 4.0 offers self-optimizing machinery, and systems work based on the environment to improve the production process.

Characteristics of a smart factory

A smart factory consists of machines and equipment, all of which are interconnected to each other in a network. Listed below are the characteristics of a smart factory.

Data analytics for optimal decision making

Data analytics uses data within the company and assesses it. It helps manufacturers understand the past and recurring factors and make better decisions using the information at hand. Other organizations can use data from different organizations to improve their production.

Custom manufacturing

One major challenge companies face is different customer specification needs. The use of Industry 4.0 offers an option for manufacturers to make customer-specific batches by using technologies such as 3D printing.

Supply chain

A transparent and efficient supply chain is a must for all manufacturers. A standard Industry 4.0 strategy has a flawless production and supply chain process. This changes how manufacturers plan their production process, from sourcing the raw materials to the end product. Companies using Industry 4.0 can predict the best time to transport their goods and deliver them to customers on time.

Advantages of Industry 4.0

Here are some of the advantages of Industry 4.0.

Gives companies a competitive edge

Using Industry 4.0 boosts an organization, giving it an advantage over companies that do not leverage it. This is because using the systems and processes makes production easier for them.

Creates a more collaborative and united team

Companies that use Industry 4.0 have systems that unify each department, allowing seamless production. It also offers the team the data and intelligence to make good decisions.

Helps spot issues in advance

Predictive analysis, real-time data, and automation help spot issues in advance. Whether the challenge is in production or shipping, Industry 4.0 helps companies note the problem in advance and offers a good solution.

Reduces costs, increases profits, and brings growth

Industry 4.0 uses software and systems that optimize the whole production process. It also gives real-time data that, when manipulated correctly, helps make correct decisions faster and increases the organization’s efficiency.

Challenges of Industry 4.0

Some of the challenges Industry 4.0 brings include:

Lack of skills

Moving to Industry 4.0 sets manufacturers in a position where computers and machinery do most of the work. When in need of workers, it becomes hard to find the needed skills. Organizations meet challenges when it comes to finding and training staff in the areas of user interface, data science, and software development.

Cyber security

Data security is a major risk when it comes to Industry 4.0. Digitalization of everything brings the opportunity for security breaches. Other challenges include misconfiguration within the systems, wrong commands, and system failures that can greatly disrupt the production of an organization.

Having everything in the organization connected to the Internet leads to a huge threat to the security of this data. There are people who focus on getting access to this data to sabotage the organization.

High upfront costs

Companies that want to move to Industry 4.0 must incur huge costs to enable the move. This proves very challenging, especially when the funds are not available.

The shift to Industry 4.0 systems requires a huge capital investment that some manufacturers may not have at the time.

Final thoughts

Industry 4.0 is here to stay. Although it is new, this revolution has huge potential because many technologies work together to optimize production processes and increase profits. Visit Alibaba.com and view more Industry 4.0 products.