Chemical reactors play a major role in the chemical separation and production process. Reactors have been used in the industry for many years and come in many types, including both homogenous catalysis reactors and heterogeneous catalysis reactors. These chemical reactors are readily available in the market right now. However, there are different reactor manufacturers, as well as an assortment of models, making it hard to know the right chemical reactors to purchase.

This article will give an overview of the market for chemical reactors, before discussing the different types of chemical or pharmaceutical reactors available and how to select the right type and model for one’s needs.

Table of Contents

Market share for chemical reactors

Types of chemical or pharmaceutical reactors

How to select the right chemical reactors

Conclusion

Market share for chemical reactors

Generally, the chemical industry has experienced considerable growth over the last couple of years. It is anticipated to surge over the period ranging from 2020 to 2030. This growth will be ascribed to the increased need for state-of-art and modern chemical reactors for efficiency in operations. Transparency Market Research highlights that the chemical reactors market has a large demand from several end-users to enable the simultaneous performance of operations in a single process.

There is intense competition from key players like Rohco Inc, Dharma Engineering, and Hexamide Agrotech Inc. These producers have indulged in research and development activities to meet consumer expectations’ needs. The chemical reactors market will continue to grow due to these investments to improve efficiency.

Across the forecast period, the Asia Pacific region will achieve massive growth in chemical reactors. This is due to increasing industrialization in countries such as China and India. Also, developments like the component of eco-friendly reactors have resulted in expansive growth opportunities in the market. Notably, Syzygy Plasmonics invested USD 5.8 million in eco-friendly chemical reactors.

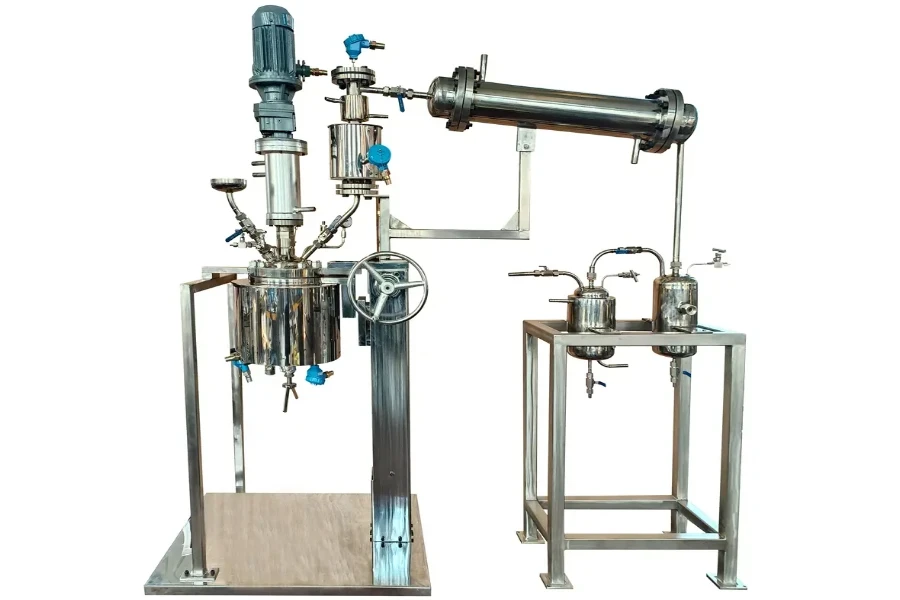

Types of chemical or pharmaceutical reactors

1. Batch reactors

Batch reactors are chemical reactors in which reactants are put in closed vessels, allowed to mix and react, and the finished items removed. The batch-wise feature means the equipment has a defined start and stop to the reaction processes. They are primarily used in the chemical industry for research and development as well as small-scale production. Exothermic reactions that require precise control of pressure, temperature, and reaction time benefit from batch reactors’ flexibility. They’re also used in the pharmaceutical, chemical, and food and beverage industries.

2. Continuous stirred tank reactors

Continuous stirred tank reactors (CSTRs) are chemical reactors involved in continuous reactions where reactants are constantly fed into the reactor as products are continually removed. CSTRs have cylindrical vessels with agitators that mix the reactants while maintaining homogenous contents. They have inlet and outlet ports for uninterrupted input and output of reactants and products. The equipment is widely used in the chemical industry due to its ability to attain steady-state reactions as the concentrations of reactants and products remain constant during and after the process.

3. Plug flow reactors

Plug flow reactors (PFRs) are chemical reactors with continuous feeding of reactants into a tubular vessel where they flow and react. The primary design of PFR includes a straight tube with an inlet and outlet ports for reactants and products, respectively. In a plug-like manner, the reactants flow via the tubular reactor, where each layer moves along without contacting the adjacent layers. In this case, there is precise control over reactions, as the flow pattern gives uniform products. They are mostly applied in the pharmaceuticals, polymers, and chemical industries in high-temperature and catalytic reactions.

4. Semi-batch reactors

Semi-batch reactors are chemical reactors that merge features of batch and continuous reactors. As such, one or more reactants are continually fed into the reactor whilst one or more other reactants are put in a batch-wise manner at one or more stations during the reaction. Apart from the closed vessel and agitator design in batch reactors, semi-batch reactors have additional ports for a constant and intermittent input of reactants. This equipment archives higher yields and conversions with close control over reaction conditions. They are generally used in the chemical industry, for pharmaceuticals, and in polymer production.

5. Catalytic reactors

Catalytic reactors are chemical reactors in which a catalyst facilitates reactions. The catalyst reduces the energy activation needed for the reaction and thus increases the reaction rate while minimizing temperature and pressure. There are various catalytic reactors, including fluidized-bed, fixed-bed, and slurry reactors. The applications of catalytic reactors in the chemical industry include oxidation, hydrogenation, and cracking. These reactions require high conversion and selectivity rates to produce high-value pharmaceuticals, petrochemicals, and plastics products.

How to select the right chemical reactors

1. Application

The application features include the nature of the reaction, the operation scale, the desired reaction conditions, and the required product yield and purity. To optimize reaction efficiency, safety, and product yield, buyers should select the appropriate type of chemical reactor for specific applications. For instance, batch reactors are used in fine chemical, pharmaceutical, and food sectors for small-scale reaction operations. The continuous flow reactors are suited for large-scale polymer and petrochemical production reactions. Additionally, stirred tank reactors have a broad range of applications in esterification, polymerization, and oxidation.

2. Working volumes

The working volume of a chemical reactor involves the reactor vessel volume occupied by the reactants during a reaction. This depends on the required production capacity, equipment cost, and availability. Generally, small reactors offer versatility but have lower working volumes. In contrast, larger reactors are cost-effective and efficient, even though they need safety measures and more complex processes. Microreactors provide a working volume range of 1-10 microliters. Lab-scale chemical reactors can attain working volumes of 100-400 milliliters. Pilot-scale reactors have working volumes of 20-150 liters. Additionally, industrial-scale reactors provide working volumes ranging between 400 to 1900 cubic meters.

3. Viscosity of contents

Buyers should consider viscosity, which is the measure of the fluid flow resistance, and it has a considerable effect on the design and performance of the chemical reactor. This depends on the reaction kinetics, the reactants’ rheological properties, and the equipment & process needs. As such, high-viscosity substances require specialized tools and modifications for effective mixing, heat transfer, and to prevent clogging. For instance, stirred tank reactors handle a wide range of viscosities. This ranges from low to medium viscosity and can be modified to be used with high-viscosity materials. However, high viscosities result in blockages and irregular flow patterns, reducing reaction efficiency. On average, for most chemical reactions, the viscosity of the reactants should be quite low, with a range of about less than 1 centipoise (cP) to a few hundred centipoises.

4. Solvents used

Generally, solvents used in chemical reactions affect the reaction kinetics, reactor performance, and product properties. Buyers should consider the physical and chemical features of the solvents, desired reaction conditions, and the equipment and process requirements. As such, aqueous solvents used in organic synthesis and biochemical reactions can be done in stirred tank reactors for efficient heat transfer and mixing. Non-polar solvents like alcohol used in organic reactions can be carried out in stirred tanks, fluidized-bed, and fixed-bed reactors. Volatile solvents require specialized reactors like continuous and batch distillation reactors.

5. Cost

Buyers should note that the cost of chemical reactors depends on various factors. These factors include size, the material used in construction, complexity, and operating conditions. They should also consider process requirements, reactor specifications, and potential investment returns. For instance, batch reactors are cheaper than continuous reactors due to their simple design. Continuous reactors have better product quality and process efficiency in high-volume production. The average cost of continuous reactors ranges from USD 10,000 to USD 50,000. On the other hand, the cost of industrial high-pressure reactors starts at USD 30,000.

Conclusion

Sourcing the appropriate chemical reactors for particular applications requires careful consideration of the factors mentioned in the above guide. It is less complex when buyers comprehend the requirements of the chemical processes. The equipment should also provide the most value for the investments made. To read more, or to view product listings of high-quality chemical reactors, visit Alibaba.com.