Table of Contents

● Introduction

● Market overview

● Different types of fuel filters

● Things to consider when buying fuel filters

● Conclusion

Introduction

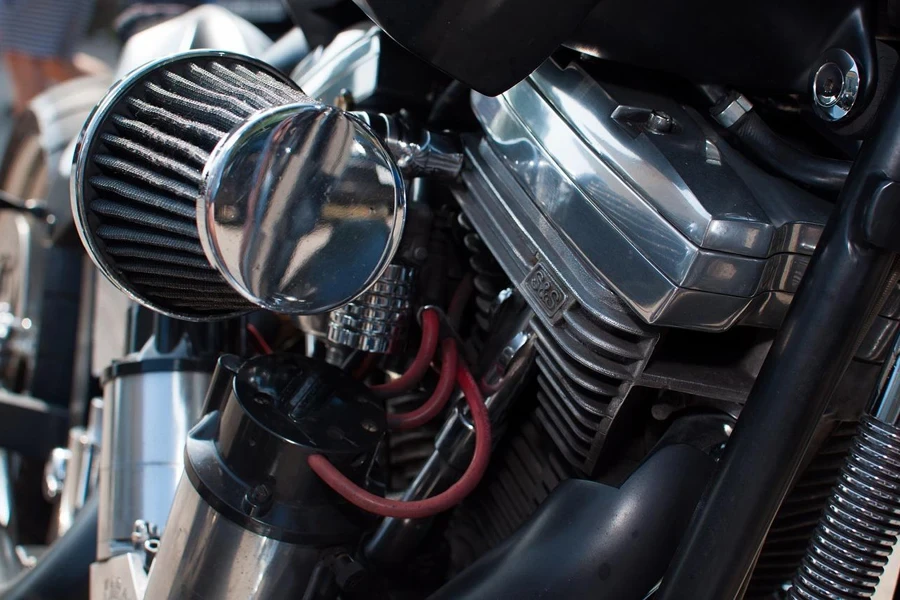

Fuel filters are known to be very vital components in the performance of the engine as well as the overall durability of automobiles. These filters help to keep most of the impurities and contaminants from gaining access to the engine, thus helping to regulate the clean flow of the fuel, which is very useful in providing appropriate combustion of fuel, therefore affording the engine the required power. Maintaining good fuel filters keeps the engine problem-free, lowers possible expenses, and increases vehicles’ dependability. Hence, choosing the right fuel filter in such an industry that strives for speed and endurance is vital for maintaining the health of engines and ensuring long-term performance. This guide goes deeper into the kinds, characteristics, and other considerations towards finding appropriate fuel filters.

Market overview

Market scale and growth

The global automotive fuel filter market was valued at USD 1.82 billion in 2022 and is expected to reach USD 12.77% billion by 2032, with a Compound Annual Growth Rate of 4.3 % between 2023 and 2032. This growth results from the rising demand for clean fuel to enhance engine performance and meet the standard of environmental tests. Fuel purifiers ensure that contaminants cannot reach the fuel injector or other parts of the engine, thus increasing the life span of the engine and its efficiency.

Regional insights

North America remains the largest consumer of fuel filters globally, with a market share of 38% in 2022. The reasons for this region’s importance are automotive industry development, strict legislation concerning emissions, and high car density. The awareness of environmental laws and the increased usage of gaseous vehicles are the other factors that increase the demand for fuel filters in North America.

Different types of fuel filters

Inline filters

Inline filters usually have a cylindrical construction with hose fittings on both ends to be easily incorporated into the fuel line. These filters employ an element of either pleated paper or synthetic material to collect dust and particles as the filter through the fuel. Inline filters are frequently available in flow rates of up to 200 litres per hour, and the working pressure is up to 7 bar (100 psi). Due to their small size, they are ideal for passenger cars and light trucks. Advantages include the fact that it is easy to install and maintain, as well as the effectiveness of the tall unit in removing particles as small as 10 microns.

Cartridge filters

Cartridges are enclosed in a disposable metallic or plastic container with replaceable filter media. The filter media are usually made from cellulose and synthetic fibre with high dirt-holding capacity and efficiency. These filters can remove particles from 5 microns, and as per the manufacturer, these filters can take the pressure up to 10 bar or 145 psi. Waste cycles are brought down, and replacement costs are low, which makes these housing units friendly to the environment. Cartridge filters are applied to diesel engines because the high purification efficiency is important for protecting fuel injectors from wearing.

Spin-on filters

Spin-on filters comprise a metal canister with a threaded base on which the filter media is placed. The filter element is often pleated cellulose or synthetic, effectively filtering particles as small as one-tenth of a millimetre. Spin-on filters are recommended to be used at pressures of up to 12 bar (175 psi); they are used in commercial vehicles, agricultural machinery, and construction machinery. This is particularly important because the design can be easily replaced in case of a failure; thus, the time needed for maintenance is minimized.

Paper filters

Paper filters, popularly applied in petrol engines, consist of good-quality cellulose fibre laid in a closely packed manner. This type of filter can filter out particles as small as 20 microns and is available in inline and cartridge types. Paper filters are intended for the flow rate of up to 150 litres per hour and the pressure reaching 5 Bar (72 Psi). They constitute a cheap means of keeping fuel neat in small- to medium-sized engines with enhanced burning and general efficiency.

Atom filters

Atom filters are designed for older and certain Japanese cars and are very basic in design with a connect-and-go type fitting. Common designs consist of a blend of cellulose and synthetic media, which can collect particles of 15 microns. Atom filters work up to the pressure of 6 bar (87 psi), with a filtration rate of about 100 litres in an hour. Due to these basic designs and dependable filtration, they are suited to moderate fuel systems where they do not require highly refined and elaborate systems for proper cleanliness.

Microglass and cellulose filters

Microglass filters are made from ultra-fine synthetic fibres that are provided in several layers to rig up the dirt-capturing proficiency of the filter. One can use such filters to screen out particles that are as tiny as 2 microns and are suitable for the new generation engines, which need extremely clean fuel. However, they have higher filtration rates and are replaced more frequently than cellulose filters. Microglass filters are pressure vessels for high pressure, up to 20 bar (290 psi).

Natural cellulose filters generally combine effective filtration and moderate pressure drop. They can collect particles as small as 10 µm and are built to work for pressures up to 10 bar (145 psi). Cellulose filters have longer change intervals and are used for classic fuel systems. They do not need extremely high filtration capabilities, which are required for keeping the engine components intact.

Things to consider when buying fuel filters

Brand and quality

The fuel filter chosen should be from reputable brands to guarantee the best performance and durability. Reliable manufacturers use high-quality materials like multisectorial synthetic fibre and superior cellulose because they have higher filtering capacity and durability. The filters in good quality normally go through tests towards parameters such as burst pressure, flow rate, and particle removal, to name a few, to meet the industry standards as required. For example, filters in the premium category tend to have sturdy end caps. They are made out of metal to accommodate high temperatures and even pressures and, as a result, provide better services.

Compatibility

The compatibility of a filter with the other parts or with the vehicle, in general, is essential when selecting the right fuel filter. These filters have to operate in conformity with the singularity of the fuel system in terms of the type of fuel (petrol or diesel), pressure calls for, and kind of connections. For instance, the direct injection engines of contemporary cars need filters that are more capable of withstanding higher pressures in access of 100 psi and are expected to segregate particles as small as 2 microns. To ensure the filter meets the engine specifications, the filter has to be perfectly fitted to avoid problems such as restricted fuel flow, which would result in poor performance and major damage to the engine. OEM specs should also be checked in the selection process to fit the correct filter that will improve the functionality of that particular unit.

Technical specifications

The main customer requirements include micron rating, flow rate, and dirt holding capacity. Micron rating refers to the ability of the filter to trap dust with a certain micron size; the lower the micron rating range, usually 2-5 microns, the more suitable it is for modern High-Performance Engines. The flow rate expressed in litres per hour (LPH) should ideally be equal or superior to the engine’s fuel consumption to prevent starvation. Since the AIR recirculation filter does not continuously clean the air through its life cycle, dirt-holding capacity is a vital factor determining the filter’s capability to provide consistent performance over long periods. Filters with higher dirt retention capability will be required to be replaced less often, overall lowering the filter maintenance cost.

After-sales support

After-sale services and warranties require attention as well. Prolific manufacturers of the item provide enduring after-sales support to their clients regarding technical assistance during installation and problem-solving services. Warranties help protect against some defects that might be present in the product, or if it fails during the warranty period, these problems would be fixed for free. For example, a filter is sold with a warranty of two years; this entails that the filter will perform to expectations throughout that period, giving assurance of its reliability.

Price-performance ratio

Determination of the price-performing characteristic involves comparing the cost that a filer faces with the characteristics of the filter. Premium filters tend to include modern technology, including nanofiber media or multiple-stage filters that offer great performance and durability. These filters might also incorporate components such as water elimination for diesel motors, which helps avoid harm from water. This can be costly initially since premium-quality products are usually more expensive; nevertheless, the benefits accrued from extra years and added defence might be a loss saver. Thus, the factors of the cost of acquisition, frequency of wear and tear, and repair costs are vital when deciding on the overall value for the cost incurred.

Conclusion

Maintaining the clean delivery of fuel through proper fuel filters is crucial to maintaining the engine’s performance and life expectancy. The market is rather diverse owing to the enhanced environmental rules and the developments in inline, cartridge, spin-on, paper, and atom filters. One can choose the right filter based on features such as brand image, compatibility, filter specs, warranty support, and the PPA (price-performance) ratio. A proactive maintenance schedule and proper selection of filters can go a long way towards eliminating costly and time-consuming engine troubles and maximizing vehicle performance.