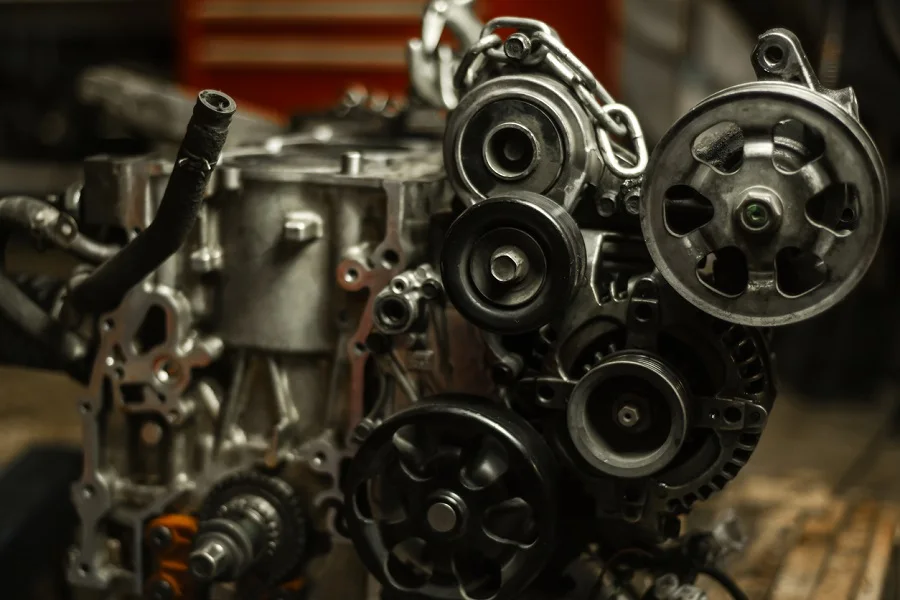

The belt tensioner, serpentine belt, and other pulleys on the drive belt system work in cohesion to power other vital car systems, such as the AC compressor, alternator, power steering, and water pump.

In this article, we will specifically look at a belt tensioner, its function, the different types, and some symptoms that tell you a change is due. Let’s get started.

Table of Contents

How huge is the belt tensioner market size?

What is a drive belt tensioner?

Types of belt tensioners

Conclusion

How huge is the belt tensioner market size?

The accounted automotive belt tensioner market size was estimated to be USD 180 million in 2023. Market experts project it to grow and reach USD 241.6 million by 2030, following a compound annual growth rate (CAGR) of 4.3% over the 2023–2030 forecast period.

This has emerged from an increase in worldwide motor vehicle automotive production, with belt tensioners being an essential car component. For instance, global production rose by 10% from 2022 to 2023.

The main players in the belt tensioner market include Tsubakimoto, KMC Automotive, Madler, Dayco, and Gates. Regarding consumption, the North American market (the United States and Canada) is the largest consumer, closely followed by the European, Asia-Pacific, Southeast Asian, and South American markets.

What is a drive belt tensioner?

A belt tensioner, or drive belt tensioner, is a pulley with a spring or adjustable movable joint that applies constant pressure to the drive belt to tighten it.

Keeping the belt tight allows mechanical power to be effectively transferred from the engine to the car’s components. In most cases, a new belt tensioner may also be required during a drive belt change that emerges from wear and tear.

Types of belt tensioners

Before we discuss the signs that show a drive belt tensioner replacement is needed, let’s look at the different types of belt tensioners.

1. Spring-loaded tensioners

This is the most popular type of belt tensioner found in cars, SUVs, and trucks. It consists of a tension spring and a swing arm to keep the serpentine belt on track in the drive belt system.

The tension is set when the tensioner is installed according to the manufacturer’s instructions. Its spring can wear down over time and cause excessive play in the tensioner arm. When this occurs, it is recommended to replace the entire unit.

2. Hydraulic tensioners

Unlike a spring-loaded tensioner whose swing arm operates with a spring, hydraulic tensioners have a hydraulic piston, which adjusts the tensioner pulley with different engine power and temperature variations.

They are mostly used in vehicles with large engines because they can withstand a wide range of motion. In a case where the hydraulic tensioner fails, the piston can be replaced.

3. Manual belt tensioner

A manual belt tensioner is used in engines that use a basic timing belt rather than a serpentine belt. The tensioner’s pulley position is adjusted with a bolt during installation and set by rotating the tensioner unit and permanently locking it at the OEM required tension.

While automatic tensioners automatically adjust themselves as the engine runs, manual ones do not move. With time, the timing belt may expand, requiring a replacement for the manual belt tensioner.

Symptoms of a failing tensioner

1. Pulley wear

One of the ways to tell that a belt tensioner is bad is by noticing pulley wear. This is mostly caused by wear and tear of the serpentine belt.

A pulley’s surface can be flat or grooved and made from steel, plastic, or steel material. Flat surfaces need to be free from cracks, chips, and dents, and the same should be true for grooved surfaces.

They should not have any cracks, dents, chips, or debris stuck in them. The high points of the grooves should be equal heights. Thus, they should be well taken care of to avoid wearing out.

If the belt pulley feels rough, it’s advisable to replace the entire tensioner, not the pulley itself, as other components may fall.

2. Rust bleed and cracks

Another sign that a belt tensioner needs to be changed is rust bleeding in the arms and base. Rust leads to damage in the arm, housing, and tensioner brackets. This can be seen by removing the tensioner from the engine block.

Rust bleeding and dripping mostly result from damaged internal components. Cracks emerge when the belt tensioner is stiff and stops moving. The best solution to this issue is to replace the belt tensioner.

3. Pulley bearing wear

A malfunctioning belt tensioner can be diagnosed by manually rotating the belt pulley by hand with the engine off and the belt removed. If any resistance, noise, or roughness is detected, these could be signs of a worn-out pulley bearing.

The issue here could be a damaged pulley or bearing. Replacing the belt should help do away with the problem.

4. Tensioner assembly misalignment

Misalignment on the belt tensioner assembly could be the reason the tensioner is faulty. It can result from incorrect installation of the tensioner, wrong positioning of the mounting bracket, and corrosion on the mounting surface or the tensioner base.

If a misalignment is visible, replacing the belt tensioner should solve the problem.

5. Tensioner arm misalignment

While finding the reason causing belt tensioner problems, one may notice unusual tracking on the belt tensioner pulley. The tensioner housing’s surface can appear shiny or have gouges or smooth streaks. This can happen when the spring housing and arm have metal-to-metal contact.

If the tensioner arm misaligns, it means that the pivot bushing is worn out and the tensioner needs to be replaced.

6. Tensioner noise

If the tensioner makes a squeaky and rattling noise, it can indicate that it’s worn out. The sound can become excessive if the bearings are failing.

Other reasons that will help diagnose a defective belt tensioner include loss of spring force, binding or grinding tensioner arm movement, excessive tensioner arm oscillation, loss of rotational force in the belt-driven components, and squealing of the belt. A new belt tensioner should be able to eradicate these problems.

Conclusion

Drive belt tensioners are crucial car components found in an engine bay that help maintain the tension in the engine belts. They can be automatically or manually adjusted and can develop issues due to wear and tear over time. This guide has provided signs that indicate that an old tensioner needs to be replaced. To learn more about the different types of belt tensioners available at wholesale prices, visit the Alibaba.com website today.