Table of Contents

1. Introduction

2. Understanding Suspension Strut Bearings and Their Applications

3. Market Trends and Developments in 2024

4. Key Factors to Consider When Choosing Suspension Strut Bearings

5. Top Models and Leading Features to Explore

6. Conclusion

Introduction

Suspension strut bearings play a key role in today’s cars by connecting the suspension struts to the vehicle body. They help with steering movements and shock absorption for a smooth ride and better comfort while driving. These bearings also help extend the lifespan of suspension parts and ensure the vehicle’s reliability. In 2025, new materials and manufacturing methods have improved these bearings’ performance and durability, making them suitable for wider vehicle models and driving conditions. With the advancement of vehicles, over time comes the importance of choosing ideal suspension strut bearings to enhance performance efficiency and ensure safety across various driving conditions.

Understanding suspension strut bearings and their applications

What are suspension strut bearings?

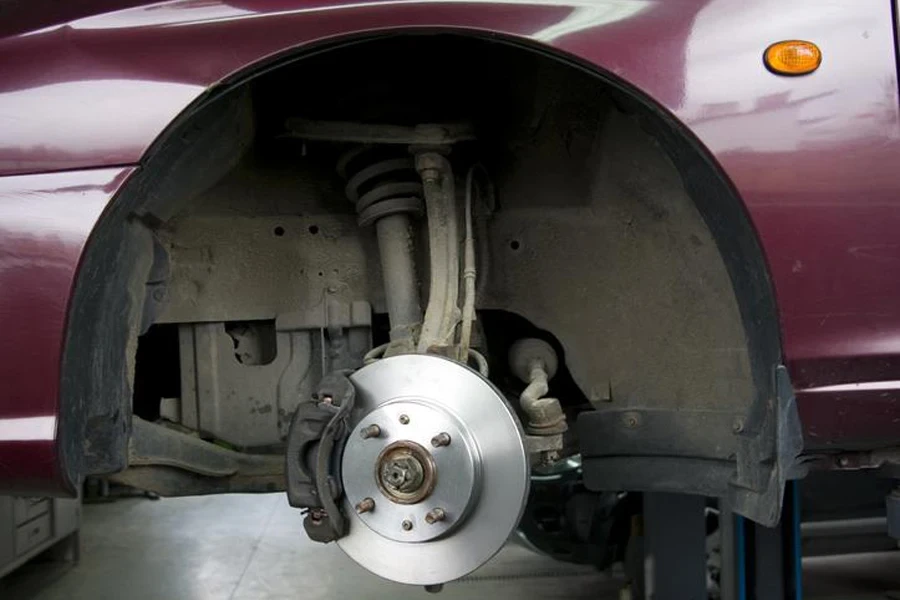

Suspension strut bearings are important in a car suspension system because they connect the strut assembly to the vehicle chassis and enable rotation during steering actions to improve handling accuracy and ride comfort. They help reduce friction and wear on suspension parts by allowing the strut to pivot, which contributes to the durability and dependability of the vehicle. Furthermore, they impact absorbing and reducing vibrations and shocks from the road, resulting in a stable and controlled driving encounter. The performance of suspension strut bearings significantly affects the car’s steering precision and the individual’s comfort.

Primary applications

Suspension strut bearings are mostly used in cars with MacPherson strut suspension systems, commonly found in passenger cars, small trucks, and some commercial vehicles. These bearings are important in passenger cars to ensure steering control and a smooth ride, especially when turning or driving over bumpy roads. For trucks and commercial fleets that usually carry heavy loads and face tougher conditions regularly, sturdy suspension strut bearings play a crucial role in maintaining the stability and performance of the vehicle. The design and materials used in the bearings can differ based on the type of vehicle and how it is used to ensure they work best for each situation. Regarding off-road vehicles, it is important to ensure that the suspension strut bearings are tough since they face tough conditions. On the other hand, sports cars that perform at a certain level might need superior bearings to help with handling.

Market trends and developments in 2024

Market data and insights

The global market for suspension strut bearings was predicted to grow over the years with an estimated worth of $45.3 billion in 2022 and is anticipated to rise to $51.6 billion by 2027 at a Compound Annual Growth Rate (CAGR) of 2.5% as outlined in a market analysis report from MarketsandMarkets in 2024. The increase was driven by the uptick in vehicle manufacturing and the need for more advanced suspension systems. Asia Pacific emerged as the leading region in this market thanks to its supply chain and key players in the industry. North America and Europe also maintained substantial market shares due to technological advancements. Prominent companies, like KYC Corporation and Bilstein GmbH, are actively pursuing innovation and strategic collaborations to stay ahead in the market.

Industry innovations

In 2024, there have been advancements in the suspension strut-bearing industry in material science. Manufacturers are adopting reinforced polymers and advanced alloys to improve durability and resistance to wear and environmental factors, extending product lifespans. Eco-friendly components are becoming a priority, with recyclable materials and sustainable manufacturing practices aligning with global ecological goals. Furthermore, integrating sensors for real-time monitoring and implementing automated precision engineering processes contribute to heightened product quality and performance, which helps meet the rising demand for efficient suspension systems.

Key factors to consider when choosing suspension strut bearings

Material and durability

Selecting top-notch materials for suspension strut bearings is crucial to guarantee their longevity and effectiveness. High-tech materials like strengthened polymers and crafted metals offer durability against wear and environmental elements, making them perfect for challenging situations. These materials decrease friction levels and prolong the bearings’ lifespan while enhancing the suspension system’s efficiency. Moreover, advancements such as self-lubricating plastics boost durability and reduce maintenance needs, which ensures reliability for a wide range of vehicle uses.

Compatibility and fit

Choosing the right suspension strut bearings is crucial to ensure compatibility and a perfect fit with your vehicle’s model specifications, as the manufacturer recommends guaranteeing integration with the suspension system. A matched bearing can improve how your vehicle handles and longevity by minimizing wear and reducing the likelihood of mechanical issues. It’s essential to get the spot on during installation to maintain your vehicle’s safety and optimal performance, as any misalignment could jeopardize the safety and performance of the car.

Brand reputation and reliability

Investing in suspension strut bearings from known brands is a practical decision to guarantee reliable quality and consistent performance over time. Renowned brands are recognized for their commitment to high manufacturing practices, frequently surpassing the standards set by the original equipment manufacturers. By selecting products from trusted manufacturers, you can count on their reliability and durability while ensuring safety by reducing the likelihood of defects or operational concerns. Moreover, opting for established brands provides access to assistance and warranty protection, thus enhancing the overall value of your purchase.

Cost vs. performance

Finding the right mix of affordability and effectiveness is key when choosing bearings. High-end bearings often come with advanced features and enhanced longevity, but they may not always be necessary for every application. On the other hand, budget-friendly options may satisfy basic requirements but might lack some performance advantages. Evaluating the specific operational demands of the vehicle can help identify products that provide the best value without compromising on essential qualities like safety, durability, and compatibility.

Top models and leading features to explore

Best suspension strut bearings for different needs

Choosing the right suspension strut bearing depends on the specific needs of the vehicle and its usage. For those prioritizing affordability, bearings designed for standard driving conditions offer reliable performance at a reasonable cost, making them suitable for everyday cars. For drivers seeking enhanced comfort, bearings engineered to minimize road vibrations and improve ride smoothness are ideal. These options prioritize advanced materials and designs that cater to comfort-focused applications. On the other hand, high-performance vehicles benefit from strut bearings built for durability and precise handling, designed to endure demanding conditions and offer superior responsiveness under heavy use.

Features that matter

Key features of high-quality suspension strut bearings include noise reduction and durability. Bearings with noise-dampening technologies reduce operational sounds, enhancing comfort during driving, especially in urban environments or on longer routes. Another critical feature is enhanced shock absorption, achieved through advanced materials such as reinforced polymers and alloys, which provide resilience under heavy loads and challenging terrains. These features not only improve the driving experience but also extend the lifespan of the suspension system, ensuring consistent performance over time and reducing maintenance requirements.

Conclusion

Choosing the right suspension strut bearings for 2025 involves weighing quality and how well they match vehicle requirements and features that boost durability and performance effectively. Giving preference to bearings equipped with cutting-edge technologies, like noise reduction and sturdy shock absorption, improves handling comfort and longevity. Buyers can achieve long-term value and maintain optimal vehicle safety and efficiency by focusing on products that meet specific application needs and align with trusted industry standards. Thoughtful evaluation of these critical factors supports informed decisions, enabling consistent performance and reducing maintenance requirements.