Vehicles are often more complicated than they appear, and among the many essential parts lurking under the hood is one part consumers don’t think about but affects engine performance: the coolant reservoir (or overflow) tank. This component might seem minor compared to major parts like the engine or transmission, yet it’s impossible to overlook its role in preventing overheating and maintaining efficiency.

When a vehicle loses coolant due to system failures, serious damage can follow in a surprisingly short amount of time. That means there’s an opportunity for retailers who stock and sell auto parts.

Here’s everything you need to consider when choosing dependable coolant reservoirs to stock in 2025.

Table of Contents

What is a coolant reservoir?

Why a properly functioning reservoir is important

Key retailer considerations: How to stock coolant reservoir tanks

1. Material quality

2. Capacity and size

3. Compatibility

4. Durability and build quality

5. Ease of maintenance

Coolant reservoirs vs. radiator overflows: Clearing the confusion

The bottom line

What is a coolant reservoir?

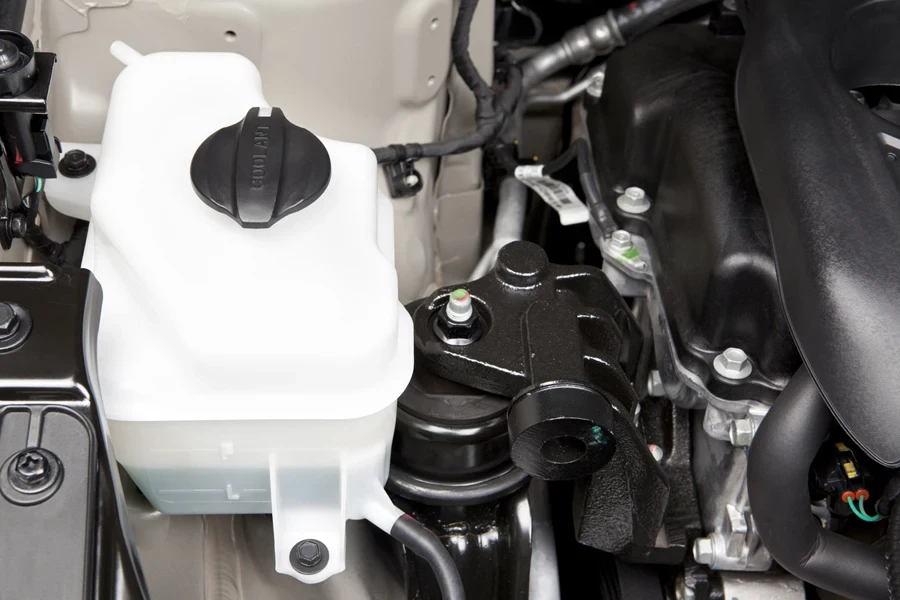

Most people realize their engine needs some fluid to stay cool, but they may only be familiar with the radiator as the primary cooling component. The coolant reservoir tank, often mounted to the side or near the radiator, acts like a backup “safety net” for excess coolant.

Since the cooling system’s temperature can climb extremely high when the engine runs, the coolant fluid (or antifreeze) expands as it heats up. It would overflow from the radiator itself if it had nowhere to go. That’s where the coolant reservoir steps in.

This container is connected to the radiator via a small hose. It receives any coolant that overflows when the engine is hot. The radiator takes back the stored coolant when the engine eventually cools down and the pressure drops. This back-and-forth movement helps maintain consistent fluid levels without constantly opening caps or manually topping fluid.

Side note: Because the reservoir also prevents coolant from splashing out onto the ground, it helps reduce waste and keeps the environment safer from chemical spills.

Why a properly functioning reservoir is important

A car’s engine offers the best and most efficient performance in a specific temperature range. Going much above that range can trigger nasty complications: blown head gaskets, warped cylinders, or even a total engine meltdown in extreme cases. By having a working coolant reservoir, drivers get a few key benefits:

- Consistent engine temperatures: If the coolant reservoir is in good shape and the system is sealed properly, the engine receives a steady supply of coolant. That consistency greatly reduces the likelihood of overheating.

- Reduced fluid loss: Since the reservoir collects fluid instead of letting it drip onto the ground, the entire cooling system remains topped up for a longer period. That means fewer refills and less waste.

- Better fuel efficiency: An engine that runs too hot or cold can impact fuel economy. By helping the system stay in the sweet spot, the reservoir indirectly contributes to better MPG.

Key retailer considerations: How to stock coolant reservoir tanks

1. Material quality

Manufacturers typically make coolant reservoirs from plastic or metal. Each has its strengths and weaknesses—here’s a closer look:

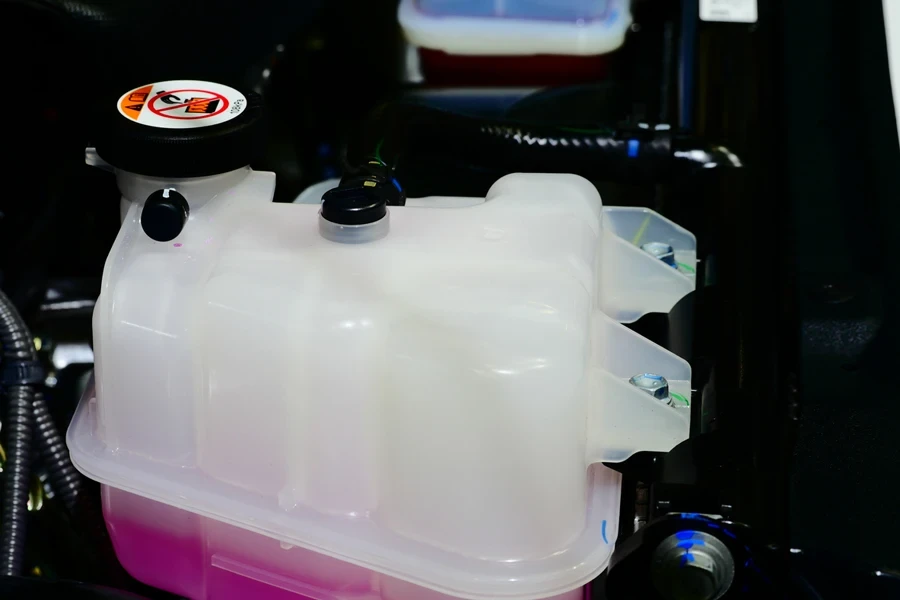

- Plastic: Usually lighter and more cost-effective. Many modern cars include plastic reservoirs from the factory, especially if the engine bay isn’t subject to extreme temperatures or heavy-duty use. High-density plastic can resist corrosion and is usually transparent enough for easy fluid checks.

- Metal tanks: These are pricier and commonly made of steel or aluminum. They can endure more severe conditions. Performance-oriented cars or heavy-duty trucks might benefit from a metal tank, thanks to their ability to withstand harsh vibrations and temperature fluctuations without cracking.

Ideally, retailers should offer options in both categories. Some drivers only need a standard plastic reservoir, while off-road or high-performance enthusiasts might specifically want a robust metal design.

2. Capacity and size

Not all reservoirs hold the same amount of fluid. Each car has recommended coolant requirements that factor in engine size, operating temperature, and expected coolant expansion. If the reservoir is too small, it may overflow, and if it’s too large, it can crowd the engine bay unnecessarily. Common sizes include 800 ml, 1 Liter, and 2 Liters—though no single “standard” size exists.

Cars also have unique engine layouts. A giant metal tank in a compact sedan’s already cramped bay can become a headache. Ensure your tanks are labeled with vehicle compatibility or generic size specs.

3. Compatibility

One of the biggest irritations for mechanics and car owners is discovering that a “universal fit” part doesn’t fit. So, retailers must ensure the coolant reservoirs they sell are marked for specific makes and models or, if universal, verify that they come with adjustable brackets or flexible mountings.

Note: Carrying products that specifically match high-demand vehicles—think popular sedans, SUVs, and pickup trucks—can quickly build a retailer’s reputation for having the right fit.

4. Durability and build quality

Durability often depends on how well a reservoir stands up to continuous temperature swings, engine vibration, and chemical exposure. Cracks or leaks usually mean a failing reservoir, so choose suppliers with a proven track record to avoid them happening fast. Look for:

- Reinforced plastic or welded seams: Extra reinforcement in the design can lengthen the reservoir’s life.

- Quality caps and seals: Cheap caps can fail under pressure, negating the benefits of a durable tank.

While it may be tempting to stock bargain-bin items, remember that a disgruntled customer who experiences a coolant reservoir failure soon after purchasing might hesitate to return.

5. Ease of maintenance

Modern reservoirs often have transparent or semi-transparent walls, making it simple to check coolant levels without opening a cap. Consider these maintenance features—they’re huge selling points:

- Visible fill lines: Clear markings that indicate “Minimum” and “Maximum” levels are handy features.

- Secure but easy-to-remove caps: Customers don’t want to wrestle with a stuck cap when checking fluid levels.

Coolant reservoirs vs. radiator overflows: Clearing the confusion

People often wonder if a coolant reservoir and a radiator overflow (recovery) tank differ. The short answer is that they’re closely related; these terms are used almost interchangeably in many modern vehicles.

A coolant reservoir acts like a regulatory chamber, storing fluid when it expands and returning it to the radiator when the pressure drops. If it fails, symptoms might include noticeable leaks, unusual coolant odors, and frequent overheating.

On the other hand, a radiator overflow (recovery tank) is usually the same idea—a place to catch extra fluid. Whether referred to as an “overflow” or “reservoir,” the aim is to prevent coolant from spilling onto the ground and ensure it can be drawn back into the system.

Either way, a properly functioning tank is crucial for maintaining the cooling system’s balance. Although these tanks are often sold under both names, their function is identical: managing fluid expansion and contraction.

The bottom line

Because it quietly regulates the ebb and flow of coolant, the reservoir tank might not get the same attention as more glamorous automotive parts. Still, it’s important for preserving engine health and keeping vehicles running smoothly. Without a properly sized, durable, and well-sealed reservoir, cars can overheat, waste coolant, and suffer expensive engine damage.

Ultimately, coolant reservoirs are crucial for any engine that needs to balance heat and pressure—basically, every engine on the road. Stocking them carefully and selling them confidently ensures customers stay safe from the dreaded temperature gauge climbing into the red.