It’s easy to forget how pivotal fuel injectors are until they fail. Drivers usually think about their vehicles in simpler terms: an engine, four wheels, and a steering wheel. Yet beneath that basic understanding lies a complex system that precisely meters fuel to the engine so that the car can run smoothly.

An integral part of this process is the injector, which is why retailers must have a grasp on how they work so that they can confidently advise customers exactly what they need.

In this article, we’ll cover everything you need to know about this nifty gadget.

Table of Contents

Why are fuel injectors so important?

A quick look at basic injector types

Mechanical systems

Electronic systems

What to consider when stocking replacement fuel injectors

1. Injector system

2. Sizing matters

3. Popularity

4. Longevity

Customer conversations: Being the go-to expert

Wrapping up

Why are fuel injectors so important?

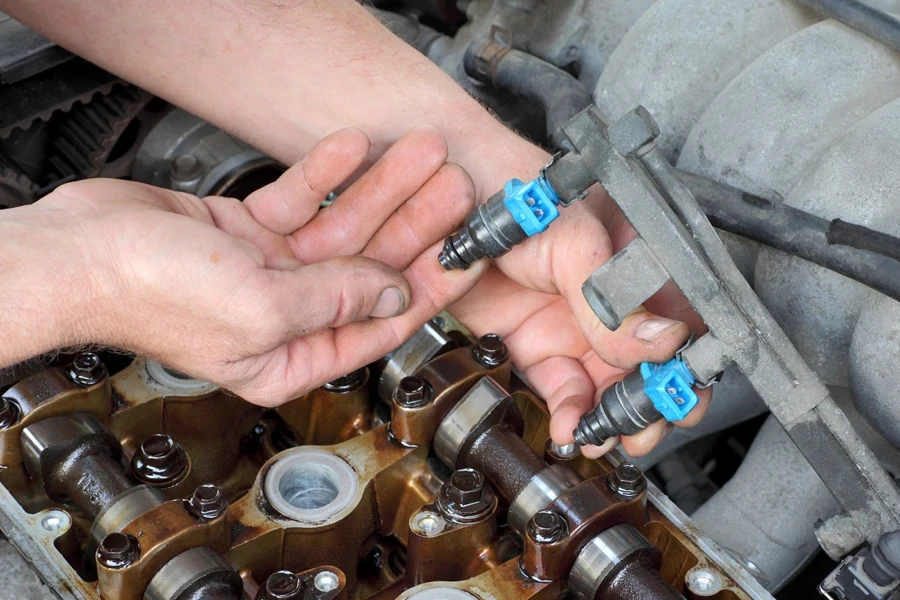

Anytime drivers press the accelerator, their car’s engine demands the correct amount of fuel at precisely the right moment – no more, no less. That’s why, if the car’s fuel injector wasn’t functioning correctly, the car might hesitate, blow out plumes of black smoke, or struggle to get up a gentle slope. And the key to a healthy injector is its continued and accurate spray of atomized fuel, delivered either to the intake manifold or directly into the combustion chamber.

Some modern engines now rely on extremely high pressures and specialized spray patterns, especially in diesel or direct-injection gasoline setups. As a result, fuel injectors have steadily evolved from simpler mechanical devices into high-tech components controlled by sophisticated electronic modules.

A quick look at basic injector types

Fuel injectors are divided into two broad categories, though the lines can blur in certain vehicles. Older or specialized setups may use mechanical injectors, while the majority of newer models use electronic types.

Mechanical systems

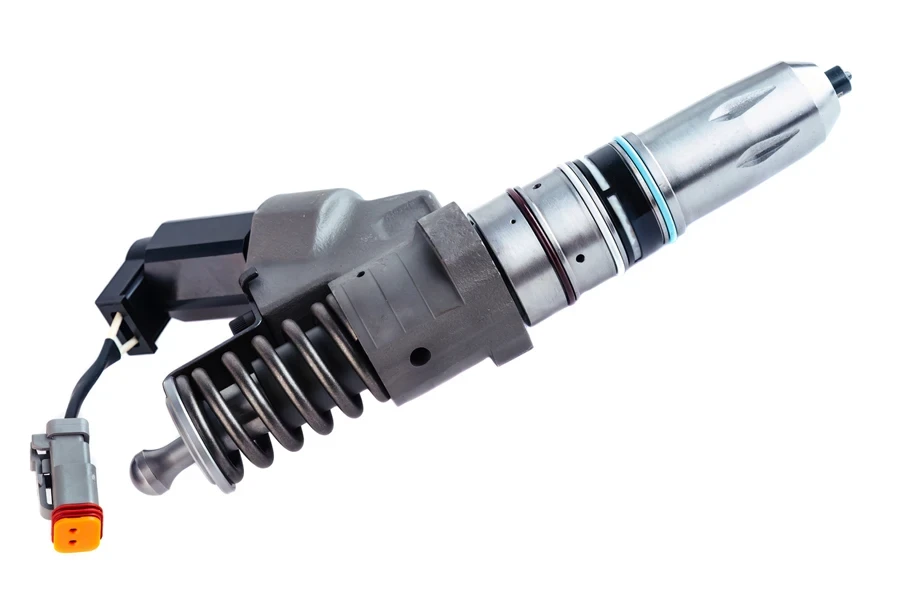

These typically rely on a cam-driven fuel pump that shoves pressurized fuel into each injector in carefully timed pulses. In some diesel engines, you’ll still find mechanical injectors that open when fuel pressure surpasses a certain threshold. While robust, mechanical injectors are less flexible in handling different engine loads or speeds.

Electronic systems

Over the last few decades, electronic systems have become more common in gasoline-powered cars and are increasingly used in diesel applications. For these, an engine control unit (ECU) calculates how long each injector should stay open based on real-time data like engine temperature, airflow, and throttle position. The result is more accurate fuel delivery and generally better efficiency, which consumers appreciate – especially when they want to get the most mileage or power from their cars.

There are also top-feed and side-feed injectors (referring to how fuel enters the injector body) or throttle-body injectors (an older approach where one or two injectors spray fuel in a central location shared by all cylinders). Retailers should be aware of these so that they can field the occasional question, particularly from owners of older cars or classic restorations.

What to consider when stocking replacement fuel injectors

1. Injector system

The injector itself is just one piece of the puzzle. There are several types of injection systems, each relying on distinct hardware and control strategies. Here’s an overview without diving too deep into engineering minutiae:

1.1 Single-point (throttle-body) injection

Sometimes called TBI, this is a modernized version of a carburetor. It consists of a single injector or pair of injectors inside a throttle body that feeds all cylinders. It was a stepping stone in the automotive world – a simpler leap from carburetion to injection before multi-port systems took hold.

1.2 Port or multi-point injection

This setup positions a separate injector for every cylinder, typically in the intake manifold near the valves. By metering fuel beside each cylinder, the system can be more precise than TBI and reduce fuel condensing issues in the manifold.

1.3 Sequential fuel injection

Think of it as a more refined version of port injection. Instead of spraying all injectors simultaneously, the ECU fires them in sync with each cylinder’s intake stroke. This helps with precision and can yield slight improvements in fuel economy or emissions. It’s more common in many mainstream vehicles from the 1990s onward.

1.4 Direct injection (DI)

The “latest and greatest” technology used in many modern engines, both gasoline and diesel. Fuel is sprayed directly into the combustion chamber under very high pressure, significantly boosting efficiency and power – though it also places heavy demands on the injectors. Additionally, DI injectors face intense heat and pressure and may need special cleaning or design considerations.

2. Sizing matters

Sizing determines the flow rate, which is another important thing to watch out for. If the fuel injector is too small, the user’s engine won’t run correctly. But if it’s too large, the driver risks flooding their engines at low RPMs.

While performance enthusiasts will “upgrade their injectors” to achieve higher horsepower – great for custom tuning or turbocharged engines – most ordinary vehicles will only need stock models.

3. Popularity

Which vehicles are common in your region? For example, if retailers operate in a community where diesel trucks are more popular, they’re more likely to want to stock a broad range of mechanical or high-pressure rail diesel injectors. If retailers mostly serve a suburban area with mid-size sedans, focusing on the typical multi-point or direct-injection units for best-selling makes and models is more suitable.

4. Longevity

Retailers should also track longevity claims and known failure points. Some say modern cars show injector issues at around 60,000 or 70,000 miles, while older engines might go well past 100,000 miles without trouble. Knowing these rough lifespans helps retailers gauge how much inventory they’ll move.

Customer conversations: Being the go-to expert

Sometimes, the trickiest part of selling auto parts is managing customer expectations. A driver might ask if buying larger “high-flow” injectors to squeeze a little more horsepower from their stock engine is okay. You can point out that while performance injectors exist, the engine’s computer (and sometimes the physical design) expects a certain flow range.

For this reason, installing too large injectors could cause poor idle or, in worst cases, lead to engine damage. There’s also the matter of an ECU tune, which is often mandatory if drivers move away from stock flow rates. Another common question is whether replacing all injectors at once is necessary.

Technically, if only one fuel injector fails, customers could swap that single one out. However, replacing the entire set can be more cost-effective in vehicles that have racked up significant miles or when the owner complains of intermittent rough running. Since the injectors will likely have been installed at the same time, upgrading them uniformly can help the engine maintain balanced performance and prevent future headaches when another injector fails a few months later.

Wrapping up

Fuel injectors are extremely important to an engine’s day-to-day health. Therefore, having a broad selection and solid knowledge about strengths, brand quality, and potential issues can set a business’s store apart.

And that’s the beauty of a small, precision component like the fuel injector: It allows retailers to demonstrate their knowledge and build customer loyalty by helping drivers to fix issues or enhance performance.