As the days grow shorter and the weather turns chillier, it is not just a sign of the approaching winter. It also heralds the commencement of the holiday season. With the excitement of festivities in the air, it’s peak time for e-commerce businesses, as customers prepare to splurge on gifts and online shopping.

During last year’s holiday season, the U.S. witnessed a staggering surge in online retail sales, reaching close to US $240 billion, with Cyber Monday recording the highest expenditure overall. As we embrace this dynamic shopping trend, an insightful report from the National Retail Federation has projected a retail growth of up to 6% for 2023, taking total forecasted sales to an impressive US $5.23 trillion.

But how can companies secure their inventory and get ready for such a massive inflow of orders? Read on to explore five strategies that can help businesses source for the holiday season with confidence.

Table of Contents

How the holiday season affects supply chains

Sourcing for the holiday season: 5 top strategies

Strategic planning is the key to successful holiday sourcing

How the holiday season affects supply chains

The holiday season, filled with happiness, festivities, and family gatherings, also brings unique challenges for small businesses and brands as they try to navigate sudden changes in demand and supply, along with rising operational costs. This period can affect supply chains in three main ways:

Increased demand

The holiday season is traditionally coupled with a significant upswing in consumer demand. This period sees online shoppers, fueled by the festive spirit, enthusiastically buying gifts, and pushing retailers’ sales to new summits.

Notably, in 2022, total holiday spending touched unprecedented heights, reaching a remarkable US $942 billion. The resulting pressure thrust upon suppliers and manufacturers can lead to potential delays or shortages, as they scramble to keep up with the rapid-paced, holiday-induced demand.

Higher costs

The demand surge for products during the holiday shopping season requires not only expedited shipping services but also the recruitment of additional seasonal staff to efficiently manage the sweeping inventory influx.

This increased operational intensity often translates into higher costs. For instance, a survey by the National Association of Manufacturers revealed that 85.7% of respondents cited the escalation of raw material costs as a primary business concern during this peak demand period.

Influx of returns

As more people choose to bestow gifts to loved ones through online shopping, the volume of unwanted or unsuitable products exponentially grows. Consequently, these unsatisfied customers contribute to an influx of returns as they attempt to exchange unwanted items for more desirable ones.

In fact, in 2021 alone, merchandise valued at over US $761 billion was returned to retailers. This trend, while cyclical, presents a considerable challenge to the smooth operation of the supply chain in the post-holiday period.

Sourcing for the holiday season: 5 top strategies

Now that we’ve identified the common challenges that the holiday season brings, the big question is: How can businesses gear up for holiday sourcing and tackle these expected obstacles with confidence and ease? Here are five strategies that will help businesses do just that:

1. Create a professional holiday calendar

An easy yet effective strategy for businesses preparing for holiday sourcing is to develop a professional holiday calendar. A well-outlined calendar not only informs staff about the pivotal dates of the year but also presents a clear roadmap of essential tasks and pressing deadlines before, during, and after the holiday season.

Here is a simple calendar template that small businesses can use to easily visualize their timeline to better manage sourcing tasks:

Alternately, resources like the free online Zoho Calendar can be extremely beneficial and handy. They facilitate sharing cardinal events with internal teams and allow for notifications for high-importance holidays such as Black Friday to be sent out ahead of time. Consequently, this helps businesses to anticipate what shopping events are on the horizon and help them to prepare and plan effectively months ahead.

2. Plan for consumer demand with accurate forecasting

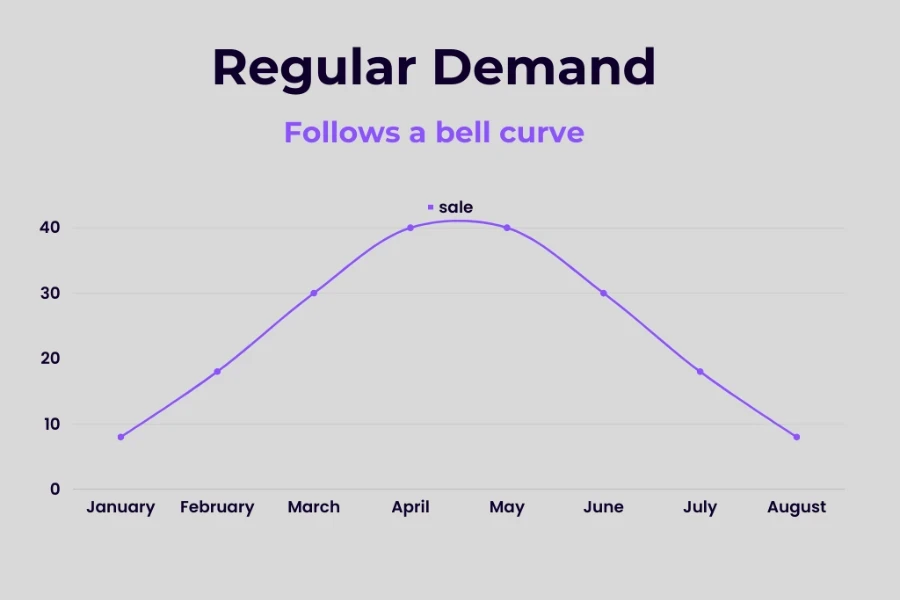

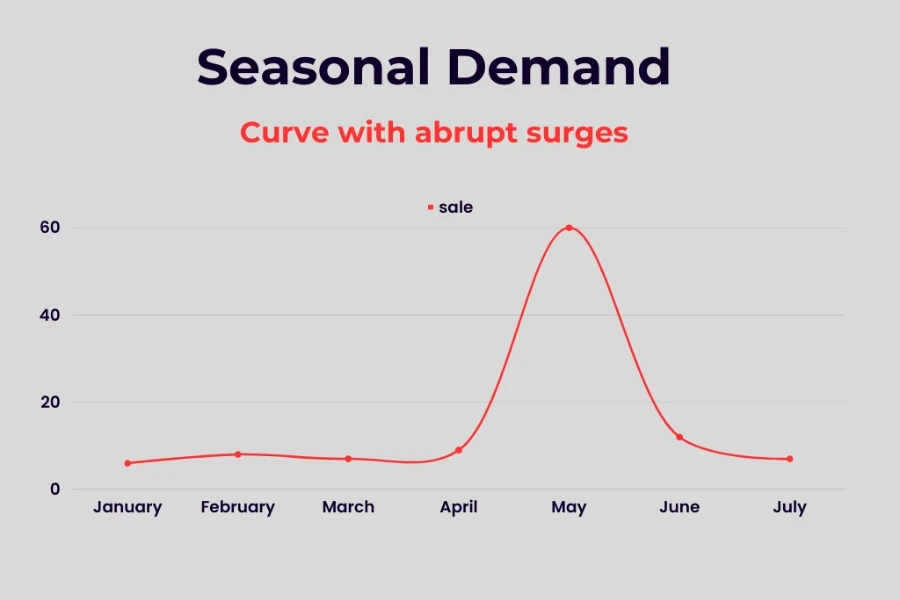

Unlike regular periods where sales typically follow a bell curve with a gradual increase, peak, and subsequent decrease, holidays often lead to an abrupt surge in customer demand. This unforeseen rise may swiftly drop to negligible levels once the holiday season ends.

The sudden rise in demand during holidays often stems from new customers drawn to discount promotions. However, businesses can use modern technologies like artificial intelligence (AI) and machine learning (ML) to plan for these rapid changes in demand. For example, they can use Alibaba Cloud’s AI platform to create algorithms that:

- Analyze social media posts, using ML models to assess sentiments and keywords related to their products or services in social media posts.

- Create demand models, leveraging AI and machine learning to analyze past transactions, online browsing, and buying behaviors, helping to predict customers’ potential purchases during the holiday season.

- Identify market trends, utilizing AI to monitor and analyze global, regional, and local market trends, enabling businesses to anticipate demands and stock up accordingly for the holiday season.

- Manage inventory with the help of AI algorithms, which can automate the inventory replenishment process, making automatic purchase orders when inventory levels fall below a certain threshold, thus ensuring the availability of products during high-demand periods.

3. Build a diversified supplier network

When it comes to holiday sourcing, relying heavily on a single supplier can be a catastrophic mistake. Picture this: a clothing retailer announces a massive holiday sale during Christmas, prompting a tremendous increase in production and shipping tasks for its foreign manufacturer.

However, the supplier, under the pressure of producing larger quantities quickly, fails to meet the lofty production targets, resulting in significant shipping delays. This scenario paints a grim picture of empty store racks during the peak sales time – a veritable nightmare for e-commerce enterprises.

To mitigate such risks, it can help to build a multifaceted supplier base. Therefore, if one supplier falls short, businesses can seamlessly shift to another part of the supply chain network, eliminating disruption in the flow of goods. Here are some guidelines and tips to follow when establishing such a diversified network:

- Supplier classification: Split suppliers into categories such as primary, secondary, etc., based on their goods offered, dependability, and geographical proximity. This stratification helps businesses have better control over their supply chain.

- Regular performance evaluation: Conducting frequent supplier assessments based on factors such as delivery time, goods’ quality, service level, and pricing can assist in determining their overall effectiveness and dependability. Check out this comprehensive checklist to measure supplier performance more objectively.

- Supplier relationships: When dealing with multiple suppliers, it’s crucial to invest in strong relationships. Having a strong rapport promotes better collaboration, improves responsiveness, and adds flexibility during supply chain disruptions. Follow these 7 supplier management tips to help build robust partnerships.

4. Develop a risk mitigation strategy for the holiday rush

Sourcing for the holiday season poses unprecedented challenges to small businesses and e-commerce brands. The last-minute rush of orders, combined with the urgency to meet delivery deadlines, can cause major headaches. As the holiday season approaches, businesses must prepare for several potential risks, such as:

- Inventory stockouts and overstocking: Misjudging the holiday demand can result in exhausting stock too quickly or amassing excess inventory.

- Unexpected supply chain disruptions: Global occurrences, be it natural disasters or political unrest, have the potential to obstruct transport or halt production, causing unwanted delays or cessation of shipments.

- Diminished product quality: Suppliers might be tempted to compromise on quality when artificially boosting production to cater to the high demand.

- Unfair competitor tactics: Rivals might indulge in aggressive discounting, host exclusive sales, or intensify their advertising to lure customers.

Given these potential problems, the need to develop a logistics risk management strategy cannot be overstated. The following are top tips to implement an effective risk mitigation strategy for the holiday rush:

- Create flexible staffing plans: Businesses should consider employing flexible staffing solutions, such as temporary workers, to handle the increased burdens of the holiday season. This can help evade operational bottlenecks and ensure smooth functioning.

- Plan for reverse logistics: Even though it might seem counterintuitive, accounting for post-holiday return volumes is vital. A well-structured return process can uphold customer satisfaction and encourage repeat business.

- Strategize for last-mile delivery: “Last-mile” delivery can be a treacherous phase, especially during the holiday rush. Cooperating with reliable local delivery services and providing alternative options, like pick-up points, can assuage this risk.

- Upgrade customer service: Businesses need to brace themselves for a surge in customer interactions. Deploying AI chatbots can help manage increased sales volumes and maintain high-quality customer service during this period.

5. Adopt joint procurement to boost purchasing power

During the ever-fluctuating holiday season, small businesses with limited resources need adequate strategies to handle their sourcing needs. One such operative strategy is the adoption of joint procurement.

Joint procurement involves identifying and partnering with other companies that have similar sourcing requirements. Together, these businesses can wield a higher bargaining power, enabling them to get better prices and extended payment periods.

But lower prices are just the tip of the iceberg; there are numerous other ways in which joint procurement can make holiday sourcing more efficient. The table below highlights the advantages of joint procurement over traditional singular procurement:

| Advantages | Joint procurement | Traditional procurement |

| Risk | Since procurement is conducted collectively, any risk is shared among the participating businesses. This could be market risk, financial risk, or supply chain risk. | In traditional procurement, the risk is carried by a single business. If any market, financial, or supply chain risk occurs, it could cause significant damage to the business without the support of other participants. |

| Market intelligence | Businesses involved in joint procurement may share market holiday insights and information and analysis about market trends and supplier performance. | Singular procurement often means all market intelligence gathering and analysis is an individual task. This could result in missing out on key trends or insights, or simply result in a much larger workload. |

| Product quality | By working together, businesses may help standardize the goods and services they purchase, which can reduce complexity and ensure consistency. | Traditional procurement relies on each business’s standards and practices, which may result in greater complexity and potential inconsistency in product or service quality. |

Strategic planning is the key to successful holiday sourcing

In conclusion, successful holiday sourcing requires meticulous planning and strategic foresight. It necessitates a year-long proactive approach, as opposed to an 11th-hour scurry. An effective plan includes professional holiday calendar creation, thorough market research, demand forecasting, and careful inventory management to avoid overstocking or understocking situations.

Are you new to such strategic planning? Take the first step to becoming a sourcing maestro with our comprehensive guide on logistics planning!