Table of Contents

1. Introduction

2. Main types and uses of wheel hubs

3. Overview of the 2024 market

4. Key factors to consider when selecting wheel hubs

5. Leading models and their standout features

6. Conclusion

Introduction

Wheel hubs are pivotal in vehicles and bicycles, serving as the connection point between the wheel and the axle. Their primary function is facilitating smooth rotation while supporting weight and transferring forces during motion. High-quality hubs improve performance by reducing friction, ensuring stability, and enhancing durability, which is crucial for achieving reliable and efficient operation. Whether in high-speed cycling or heavy-duty automotive applications, the right hub can significantly impact overall functionality, safety, and long-term maintenance needs. Investing in the right hub technology can streamline operations and elevate product value, meeting the diverse demands of modern performance standards.

Main types and uses of wheel hubs

Types of wheel hubs

Different wheel hubs play key roles in bicycles, vehicles, and specialized equipment with specific functions in mind. For instance, bicycle hubs like road bike hubs prioritize lightweight performance or mountain bikes designed for challenging terrains. Automotive hubs come in various forms, from those with separate bearings that need frequent upkeep to modern integrated hub assemblies that merge hubs and bearings for a hassle-free maintenance experience. Specialty hubs cater to unique needs, such as tandem hubs for additional weight capacity, e-bike hubs with integrated electric motors, and industrial hubs engineered for heavy-duty loads or high-speed precision.

Roles and applications of wheel hubs

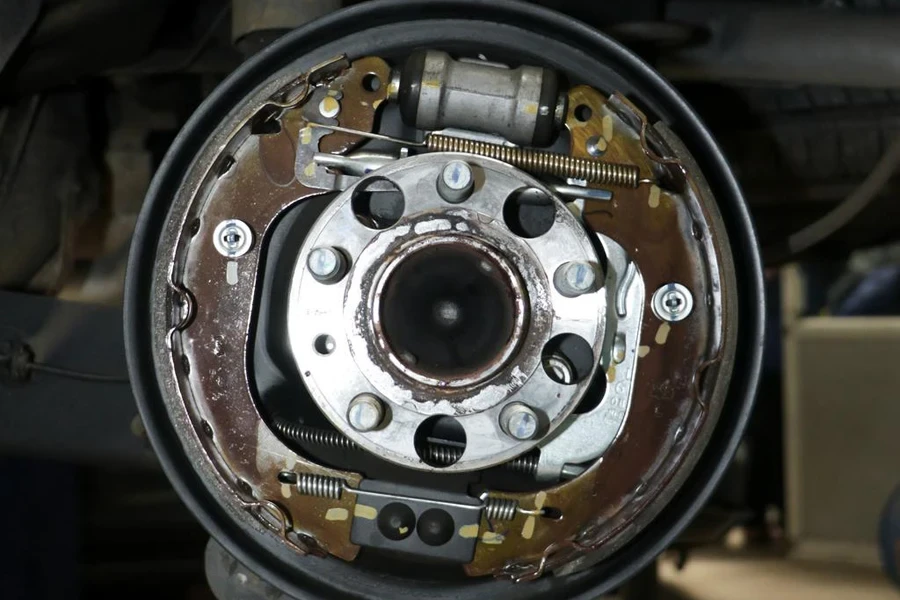

Wheel hubs are critical in transmitting forces and ensuring smooth motion across various systems. In bicycles, hubs transfer pedaling energy and terrain impacts efficiently to the frame while reducing friction for better performance. In vehicles, hubs maintain rotation, alignment, and braking stability, directly influencing safety and reliability. Specialized hubs meet unique requirements, enabling tandem cycling, powering e-bikes, or supporting precision machinery in industrial settings, making them indispensable for diverse applications.

Overview of the 2024 market

Growth Projections and Demand Drivers

The global wheel hub market demonstrated strong growth in 2024, driven by the expanding automotive and cycling industries. According to Prof Share Market Research, the automotive wheel hub market was projected to reach USD 133.58 billion by 2031, with a CAGR of 6.2% from 2025 to 2031. This growth was fueled by increased vehicle production in emerging markets and rising demand for lightweight, high-performance components.

In the cycling sector, the hub motor market was forecasted to grow from USD 11.93 billion in 2025 to USD 16.08 billion by 2030, reflecting a CAGR of 6.45%, as noted by Towards Automotive. This expansion was driven by the growing popularity of e-bikes and the emphasis on sustainable transportation solutions. In 2024, advanced hub technologies that enhanced performance and reliability became a prominent choice for consumers in the cycling market.

Key industry trends

In 2024, the advancements in the wheel hub sector are due to technological progress and changing consumer tastes. Materials such as aluminum alloys and carbon composites became more widespread, reducing weight and enhancing handling and fuel efficiency. Additionally, ceramic bearings rose in popularity because of their durability and minimal friction, which provided extended longevity. Advanced sealing technologies enhanced hub reliability by protecting against contaminants and minimizing maintenance needs.

The growing adoption of electric vehicles (EVs) in 2024 influenced hub designs to accommodate regenerative braking and handle higher torque outputs. The cycling industry has seen an increase in the need for lasting and easy-to-maintain hubs in city settings, which has led to advancements in the materials and functionality of these components. The focus on customizability and environmental sustainability has also become a trend as people look for personalized designs and eco-conscious materials to align with their preferences and green objectives.

Key Factors to Consider When Selecting Wheel Hubs

Material and durability

The material chosen for a wheel hub significantly affects its strength, weight, and durability. Alloy steel is employed for heavy-duty due to its tensile strength and longevity. Aluminum hubs balance strength and weight, offering corrosion resistance and reduced mass, which makes them ideal for performance-focused applications. Ceramic bearings, often used within hubs, are valued for their hardness and low friction, contributing to smoother operation and extended service life. However, they can be more expensive and require careful installation handling.

Compatibility and design features

If you want everything to work smoothly and efficiently, the hub must match the axle used—whether it’s a quick-release type or a thru-axle system. Also, you must ensure it’s compatible with the brake system because hubs made for disc brakes are not the same as those for rim brakes. The hub’s flange design should also align with the intended spoke configuration to maintain wheel integrity and performance. Attention to these details prevents mechanical issues and ensures safety.

Performance and maintenance

High-quality bearings within the hub reduce rolling resistance and enhance efficiency. Sealing efficiency is another vital aspect; effective seals protect against dirt and moisture, prolonging the hub’s lifespan and reducing the need for frequent maintenance. Ease of service is also important; hubs that allow straightforward bearing replacement or adjustment can minimize downtime and maintenance costs. Regular inspection and maintenance are recommended to ensure ongoing optimal performance.

Weight and cost efficiency

Reducing weight is often prioritized in racing applications to enhance speed and handling. Aluminum hubs or those with carbon components can offer weight savings, though they may come at a higher cost. For heavy-duty or utility purposes, durability takes precedence over weight, with steel hubs providing the necessary strength and longevity. Balancing weight considerations with cost and intended use ensures that the selected hub meets performance expectations without unnecessary expenditure.

Leading models and their standout features

Bicycle hubs

Top-quality bike hubs are created to offer strength and smooth spinning while handling various riding environments effectively. One common choice among road cyclists is lightweight hubs featuring ceramic bearings that help decrease resistance and enhance performance efficiency. These hubs typically feature advanced engagement systems for precise power transfer and easy maintenance, making them ideal for competitive scenarios.

For off-road and mountain biking, robust hubs with reinforced construction and high-quality stainless steel bearings are preferred. These hubs are designed to withstand harsh terrains while maintaining consistent performance. Their adaptability to different axle types and compatibility with disc brake systems add versatility, ensuring reliable functionality across diverse environments.

Automotive wheel bearings

In the automotive industry, wheel bearings with cutting-edge sealing technology are preferred for their ability to withstand elements like dust and moisture. These advancements increase the bearings’ longevity and reduce the need for frequent maintenance. High-load bearing designs are particularly beneficial for vehicles subjected to demanding conditions, such as heavy loads or frequent braking.

Premium automotive hubs often feature double-row bearing configurations that enhance stability and improve vehicle handling. These designs cater to various vehicles, from compact cars to larger SUVs and trucks, ensuring smooth operation under varying driving conditions.

Premium and innovative designs

Innovative hub designs focus on longevity, reduced maintenance, and enhanced performance. Some premium hubs incorporate engagement systems that ensure quick response and efficient power transfer, while others feature materials that balance lightweight construction and structural strength.

In both cycling and automotive applications, advanced hubs emphasize serviceability and adaptability. Models that allow easy bearing replacement or adjustment provide long-term reliability, while designs optimized for specific performance needs ensure suitability for various uses. These innovations highlight the industry’s commitment to meeting the demands of diverse operational environments.

Conclusion

Selecting the right wheel hub is critical to ensuring optimal performance, durability, and efficiency across various applications. From lightweight materials to advanced sealing and compatibility features, modern hub designs cater to diverse needs, whether for competitive cycling or demanding automotive uses. Attention to factors like material quality, bearing performance, and ease of maintenance helps maximize functionality while minimizing long-term costs. By aligning hub selection with specific operational requirements, businesses can achieve reliable and efficient performance, reflecting the advancements and versatility that define the 2025 wheel hub market.