Table of Contents

1. Introduction

2. Main types and their applications

3. Current market trends for wheel weights

4. Key factors to consider when choosing wheel weights

5. Best-selling wheel weight types and features

6. Conclusion

Introduction

Balanced wheel weights are crucial for maintaining stable wheel rotation in vehicles by addressing imbalances effectively, which can result in issues like vibrations and uneven tire wear if left unchecked. The choice between clip-on or adhesive wheel weights plays a role in influencing how well a vehicle performs in handling and safety. Materials such as steel, zinc, and lead each have their advantages regarding aspects like durability, eco-friendliness, and cost-effectiveness. By understanding each type’s specific applications and advantages, businesses can choose products that align with quality standards and meet diverse performance needs.

Main types and their applications

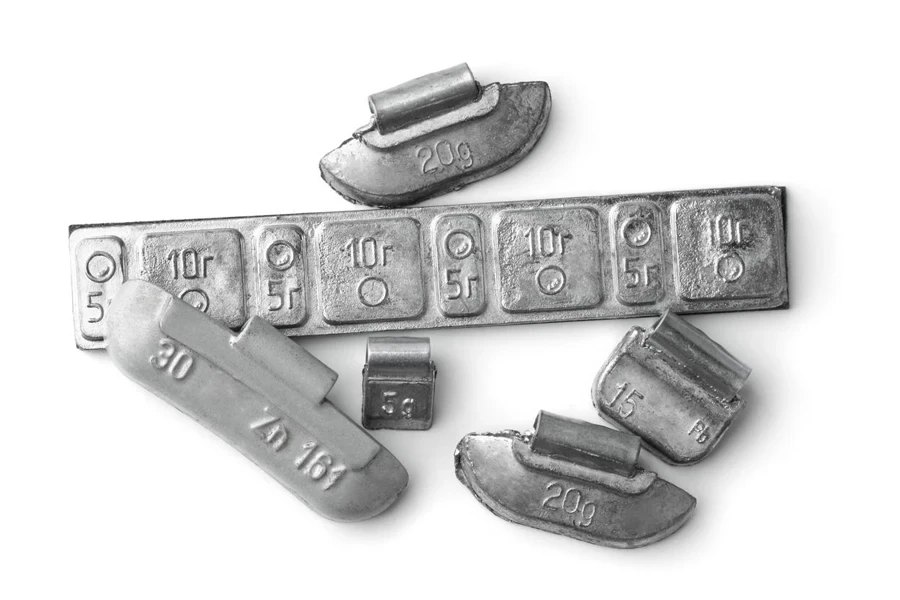

Clip-on wheel weights

Clip-on wheel weights are commonly used to balance vehicle wheels due to their straightforward installation process and secure fit onto the wheel rim flange for effortless application and removal. These weights are well suited for various vehicles like passenger cars and trucks. They are particularly effective for steel rims as they provide a secure grip that minimizes the chances of shifting while driving.

Clip-on balancing weights are great for situations where longevity and straightforward installation are factors to consider. It’s important to ensure that the clip style aligns well with the rim shape to prevent any problems, like shifting or harming the rim while in use.

Adhesive (stick-on) wheel weights

Adhesive or stick-on weights offer a versatile and aesthetically pleasing solution for wheel balancing. Unlike clip-on weights, which attach to the rim flange, adhesive weights stick directly onto the wheel’s surface. This makes them suitable for alloy, custom, and high-performance wheels where maintaining a clean look is important. Since they can be applied behind the spokes or integrated into design elements, adhesive weights are less visible, preserving the visual appeal of the wheels.

One key advantage of adhesive weights is their universal compatibility. They can be used on many wheel types without needing specific clips or profiles, making them a preferred choice for many vehicle owners. However, proper installation is crucial. The surface where the weights will be attached must be thoroughly cleaned to ensure a secure bond. Manufacturers often recommend using pre-cleaning wipes or wheel cleaners to remove contaminants such as brake dust and grease, which could affect adhesion.

Both types of weights play essential roles in ensuring smooth and efficient wheel performance. The choice between clip-on and adhesive weights should consider vehicle type, wheel design, and specific performance requirements.

Current market trends for wheel weights

Global market insights

According to Sheng Shi Wei Ye, the global wheel weight market is approximately USD 727.8 million as of 2024. They expect it to grow to USD 1.35 billion by 2034, driven by a compound annual growth rate (CAGR) of 6.4% over the forecast period. The market’s expansion is supported by increasing automotive production, regulatory shifts towards environmentally friendly materials, and growing aftermarket demand, especially in regions like Asia-Pacific, North America, and Europe.

However, the shift towards electric vehicles (EVs) could present challenges. EVs typically feature lighter wheels that require fewer or lighter wheel weights, potentially reducing overall demand in the long term. Nonetheless, the growing demand for high-performance and luxury vehicles, which often have larger wheels and higher precision requirements, continues to fuel the market for premium, non-lead weights. Key industry players are also expanding their presence through strategic alliances, acquisitions, and investments in R&D to stay competitive in this evolving landscape.

Shift towards environmentally friendly materials.

In response to rising worries about the environment and public health issues, the wheel-making industry has experienced a change away from items containing lead. Authorities in Europe and the United States, among other areas, have enforced restrictions on the utilization of lead in car components, decreasing its application. Consequently, producers have begun to embrace substitute materials like steel, zinc, and combination metals to meet the demand.

Steel has become a top choice due to its reduced environmental impact and ability to be recycled easily and it is readily available. It is also preferred because it can be effectively coated to prevent rust and improve longevity. Although not commonly used as steel, zinc is appreciated for its density and resistance to corrosion. However, its environmental footprint is still scrutinized, encouraging ongoing research into even greener options. Innovations such as Plasteel®, which features a steel core encased in a plastic shell, reflect the industry’s drive towards environmentally safe and efficient alternatives.

Key factors to consider when choosing wheel weights

Material selection: Pros and cons

The choice of material significantly impacts wheel weights’ performance, cost, and environmental footprint. Traditionally, lead was favored for its high density, which allowed for compact, effective weights. However, several areas have prohibited its usage because of its nature, resulting in a transition towards substitutes such as steel and zinc. Steel has gained popularity for its ability to be recycled and cost efficiency, but its reduced density requires larger weights, which may not always be visually appealing. Although zinc is not as dense as lead, it provides flexibility and resistance to corrosion, making it an option despite having a greater environmental impact than steel.

Accuracy and durability

Accurate calibration is essential for effective wheel balancing. Weights must be precise to ensure smooth rotation, which reduces tire wear, improves handling and enhances vehicle safety. Variability in weight can lead to imbalances, causing vibrations and discomfort. Durability is equally important; weights must withstand different driving conditions without corroding or detaching. When properly coated, steel weights resist rust, while zinc’s natural resistance to corrosion makes it suitable for regions with harsh weather. The durability of the attachment, whether adhesive or clip-on, is also crucial to maintaining balance.

Installation method and compatibility

Choosing between clip-on and adhesive weights depends on the wheel type and aesthetic considerations. Clip-on weights are practical for steel rims and are quick to install, making them ideal for standard and commercial vehicles. However, they might not be suitable for alloy or custom wheels, as they can cause scratches. Adhesive weights, on the other hand, are preferred for high-performance and alloy wheels. They can be discreetly placed behind spokes, providing a cleaner look. Proper surface preparation is vital for adhesive weights to ensure a strong bond, reducing the risk of detachment over time.

Regulatory compliance and environmental impact

Compliance with environmental regulations has driven the shift from lead-based to more eco-friendly materials like steel and zinc. The European Union led the way with a lead-weight ban, followed by similar measures in the U.S. and other regions. Steel is considered the most environmentally friendly due to its recyclability and lower toxicity, while zinc remains a viable alternative, particularly for its flexibility and durability. Businesses must be aware of these regulations to ensure their products are market-compliant, as adopting sustainable practices can also enhance brand reputation.

Best-selling wheel weight types and features

In 2025, the following types of wheel weights will become best-sellers in the market due to their specific features and advantages. Understanding these product characteristics can help identify which options may best suit particular needs, from durability to ease of application.

Popular clip-on wheel weights

Clip-on weights are favored in the market for their ease of installation and reliable grip on steel and coated rims. Common among best-sellers are those made from steel and zinc, materials chosen for their durability and resistance to corrosion. Clip-on weights are designed to attach securely to the wheel flange, which makes them less likely to detach even under tough driving conditions. High-quality clip-on products often feature coated finishes that protect against rust and reduce the risk of scratching the wheel surface, making them ideal for both standard and custom vehicles. These characteristics ensure they remain popular for vehicles needing robust, straightforward balancing solutions.

Leading adhesive wheel weights

Adhesive weights, or stick-on weights, are among the top-selling products for alloy and high-performance wheels due to their low-profile design and clean aesthetic. They adhere directly to the inner wheel surface, which makes them less visible and ideal for custom wheels where appearance matters. Best-selling adhesive weights typically have strong, weather-resistant adhesives that ensure they remain securely attached under various conditions, from high temperatures to wet environments. Products that incorporate high-quality adhesive tapes or coatings are particularly valued for their ability to resist peeling or detaching over time, providing consistent balance for the wheel. Additionally, easy-to-peel designs that simplify the application process have contributed to their popularity, especially for aftermarket installations.

Key features of top-performing products

Among the commonalities seen in best-selling wheel weights, several features stand out. Lead-free products have seen increased market demand due to global regulatory shifts away from toxic materials. Steel and zinc weights, in particular, align with this trend by offering environmentally friendly alternatives that still provide robust performance. Corrosion resistance is another essential feature, ensuring longevity and reducing maintenance needs. Additionally, the flexibility of adhesive weights, which allows them to contour to different wheel shapes, has made them a preferred choice for various vehicle types, including sports cars, trucks, and SUVs.

Conclusion

Choosing the right wheel weights is essential for ensuring vehicle safety, performance, and compliance with environmental regulations. From clip-on to adhesive options, the market offers diverse solutions tailored to specific needs in 2025. Popular materials like steel and zinc provide durability and eco-friendly alternatives to traditional lead weights. Key features such as corrosion resistance, strong adhesive properties, and easy installation contribute to the best-selling products. Understanding these characteristics allows businesses to make informed decisions, ensuring they source reliable and high-quality wheel weights that meet industry standards. As the market evolves, focusing on durability, environmental compliance, and innovation will remain crucial for success.