Due to the sheer number of components you must consider at once, managing your auto parts inventory may feel overwhelming. A service workshop’s management of spare parts is a crucial task, and because of their relatively smaller size and operating cost constraints, managing spares can be time-consuming.

The workload would mean workshop owners are typically hesitant to commit their time, money, and energy to handle spares and find it a cost-exhaustive function.

Table of Contents

Automotive cooling system auto parts management

Successfully managing cooling system auto parts

Conclusion

Automotive cooling system auto parts management

Without proper management practices, there would be unscrupulous activities that would alter the finances and overall operations of a business. This is one of the core reasons why auto parts management is such a big deal for automobile business owners with warehouses.

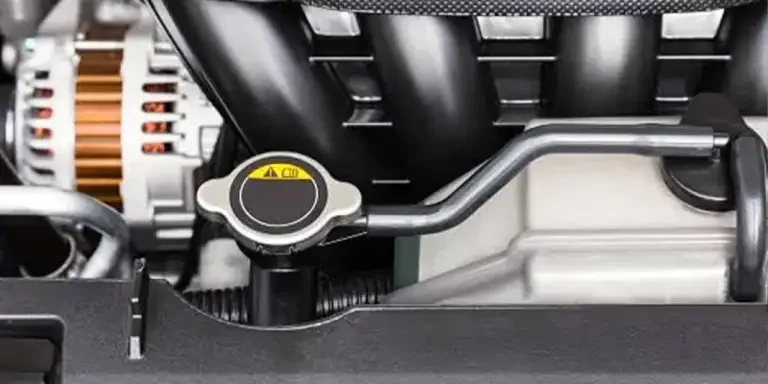

Preserving an automobile cooling system typically requires a substantial amount of effort as it affects the engine’s function to a large extent. It is general knowledge that the engine is the powerhouse of the vehicle. Therefore, the cooling system needs to be regularly checked to ensure that all spare parts run at moderate temperature levels at all times for a vehicle’s optimal performance.

Maintenance checks for automobile cooling systems

Regular coolant tests are an integral part of maintenance for a cooling system. The more checks it gets, the longer the shelf life it will likely have. Therefore, a good coolant testing kit is a worthy investment for a spare parts warehouse.

A typical kit will contain a refractometer for freeze and anti-freezing water tests, strips for regulating moisture buildup to prevent metal corrosion, coolant test strips for checking liner pitting, and coolant dilution.

Winter is the trial period for all metal spare parts and the cooling system is no exception. During this time, the risks of corrosion and discoloration are usually on the rise, so frequent coolant testing will come in handy.

It is essential to note that a cooling system is a body of components. These components include, but are not limited to, the radiator, thermostat, gasket water pump, overflow tanks, freeze plugs, and hoses. The various components have individual functions and not all of them are made with the same material; hence preservation and maintenance practices for each may vary.

Maintenance benefits of (cooling system) auto parts ventures

When maintenance checks are duly followed, all systems within the business will meet (and even surpass) market standards. The better the condition of the cooling systems, the happier the end customers will be.

Furthermore, properly maintained cooling systems can reduce the costs of operation and efficiently preserve the quality of the products. All errors and mistakes present in the spare parts will be duly corrected to ensure optimal performance of the end vehicle.

Successfully managing cooling system auto parts

There is an endless stream of available customers for cooling system auto parts dealers. Regardless, sheer market demand is not a guarantee that every auto parts venture will succeed.

Without a proven strategy, the expansion of a cooling system auto parts business might be halted. Here are some proven ways to expand a spare parts venture as a vendor:

1. Create a proper operating strategy

A proper operating strategy is one of these factors. This entails all the resources and procedures set aside to efficiently support the maintenance of the system. An operating strategy also provides a form of insurance for the cooling system in the event of unpredictable problems that may affect its market value.

2. Identify reliable suppliers

Auto parts dealers must ensure they have high demand for high-quality cooling system spare parts at all times. The importance of a reliable supplier that steadily supplies top-notch products cannot be overestimated.

To pick the best supplier for the business, vendors must be ready to make a concerted effort. While interviewing prospective suppliers, business owners must inquire about the turnaround times, shipping details, as well as minimum purchase orders. It is recommended that you only pick the supplier that extensively meets the demand of the business.

3. Manage spare parts inventory

Inventory management is crucial to every business owner who is keen on increasing the stock value of their operation. Storage records of the cooling system will give business owners insight into all the critical and non-critical categories of machinery. Furthermore, with a proper review of the inventory, all loose ends that pose a risk to growth in stock can be handled efficiently.

4. Invest in efficient manpower

The size of the warehouse operation determines which officer is responsible for the maintenance and preservation of the cooling system. Business owners may decide to handle this aspect of the business themselves, as it is an integral part of business operations. However, it is recommended that the task be left to specialized hands who are well-equipped to handle this.

Conclusion

The competition in the automotive industry is cut-throat. With this in mind, a proper operating strategy, good inventory management skills, efficient manpower, and a reliable vendor are guaranteed to help you outrun the fierce competition in the spare parts market and remain at the top of the market chain. Managing spare parts no doubt requires a substantial amount of capital, effort, and strategies. However, all of these are bound to pay off eventually.

Finding a competent supplier may seem like a complex process, especially for a first-time vendor. But this process can be made even easier by the one-stop shop, Alibaba.com. Everything a beginner or advanced cooling system venture may need can be found in the online platform’s cooling system auto parts section.