Nitrogen-making machines have become indispensable tools for industries and organizations seeking a cost-effective and efficient on-site nitrogen gas production solution.

These machines extract nitrogen from the surrounding air, eliminating the need for traditional storage and transportation methods. By providing a consistent supply of nitrogen gas on demand, they mitigate the risks of running out or relying on external suppliers. However, the proliferation of nitrogen-making machines in the market has made selecting the ideal one challenging.

This article will discuss the different types of nitrogen-making machines available and how to select the ideal one. Also, it will have an overview of the nitrogen-making machines market.

Table of Contents

Industrial nitrogen generator market

Types of nitrogen-making machines

How to purchase the perfect nitrogen-making machine

Summary

Industrial nitrogen generator market

Based on the research conducted by MarketsAndMarkets, the worldwide market for industrial generators attained a value of USD 4.2 billion in 2021. The study anticipates that by the conclusion of 2026, this figure will increase to USD 5.5 billion, exhibiting a compound annual growth rate (CAGR) of 5.4% during the projected period.

The increasing need for nitrogen in manufacturing and food processing industries drives the high demand for nitrogen-making machines. These machines offer a cost-effective and efficient solution, generating nitrogen on-site and eliminating reliance on external suppliers. Additionally, their environmental benefits, including reduced carbon emissions, align with the growing emphasis on sustainability.

Regions with high demand for nitrogen-making machines include North America, Europe, Asia-Pacific, the Middle East, Latin America, and Africa.

Types of nitrogen-making machines

1. Membrane nitrogen generator

The membrane nitrogen generator employs a principle of selective permeation to separate nitrogen molecules from the air’s other components. This machine comprises hollow fiber membranes featuring tiny pores that facilitate the passage of nitrogen while effectively blocking oxygen, water vapor, and other gases.

The generator extracts nitrogen by applying pressure to the air stream, ensuring a continuous flow of nitrogen gas. Membrane nitrogen generators are renowned for their compact size, energy efficiency, and suitability for applications requiring moderate nitrogen purity levels.

2. Pressure swing adsorption (PSA) nitrogen generator

PSA nitrogen generators employ an adsorption process to separate nitrogen from the air. These generators consist of two towers filled with either carbon molecular sieve (CMS) or zeolite material. The compressed air is directed into one tower while the other undergoes regeneration.

During this process, the CMS or zeolite selectively adsorbs oxygen, carbon dioxide, and other impurities, enabling nitrogen to pass through. Once the adsorption cycle is complete, the roles of the towers switch, ensuring a continuous supply of nitrogen. PSA nitrogen generators offer flexibility in adjusting nitrogen purity levels and find extensive use in industries that require high-purity nitrogen.

3. Cryogenic nitrogen generator

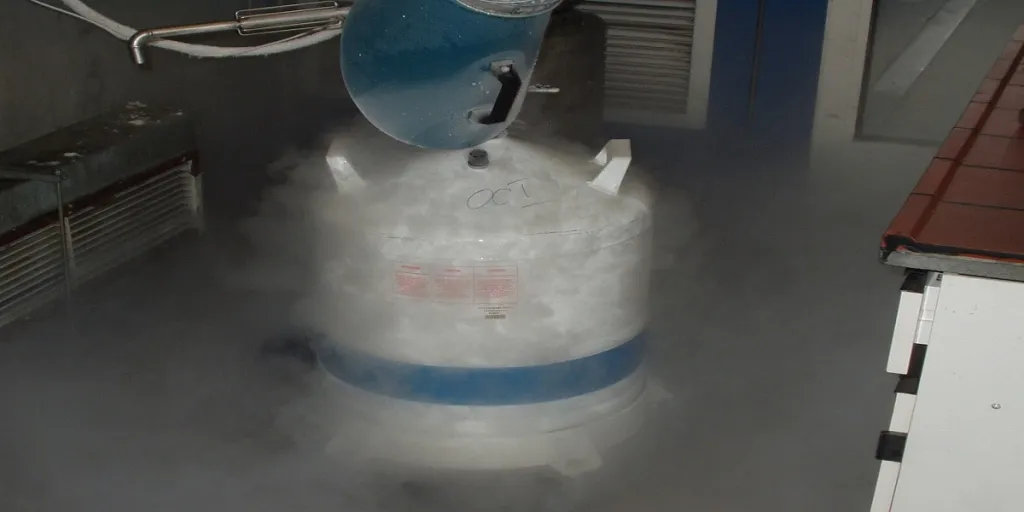

Cryogenic nitrogen generators utilize the process of liquefaction and fractional distillation of air to generate nitrogen. These generators use refrigeration to cool the air, causing its components to condense. The condensed air is separated into various constituents through distillation, with nitrogen and oxygen being the primary components of interest.

The nitrogen gas is collected as the desired product, while the remaining components are vented. Cryogenic nitrogen generators can produce high-purity nitrogen and are frequently employed in industries requiring ultra-high purity levels or substantial quantities of nitrogen.

How to purchase the perfect nitrogen-making machine

1. Purity level

Various nitrogen-making machines offer different levels of nitrogen purity, providing options ranging from standard industrial-grade purity, typically within the range of 95% to 99%, to high or ultra-high purity levels of 99.999% or higher. Understanding the precise purity requirements, you can effectively narrow down the options and choose a machine that meets your needs. Whether you need nitrogen for general industrial purposes or specialized applications demanding exceptional purity, considering the desired nitrogen purity level is essential.

2. Type of machine

Evaluate the options available, including membrane nitrogen generators, pressure swing adsorption (PSA), and cryogenic nitrogen generators. Choose the type that aligns with your requirements, including your application needs, budget constraints, and desired nitrogen purity level.

3. Durability

Consider nitrogen-making machines constructed with high-quality materials to ensure long-term performance and minimal downtime. Look for features such as corrosion-resistant components and a well-engineered design capable of withstanding the operational demands of a specific environment.

The average lifespan of nitrogen-making machines can vary depending on factors such as usage, maintenance, and the quality of components. Generally, well-built nitrogen-making machines can generate reliable nitrogen for 10 years.

4. Price

Take into account not only the initial cost but also the long-term operational expenses, such as energy consumption and maintenance requirements. The average cost of nitrogen-making machines can vary depending on factors such as the type of machine, capacity, and desired nitrogen purity level. On average, the prices of these machines can range from around $3,000 to $50,000 or more. Know the upfront and ongoing operational costs to assess the affordability and value of the machine over its lifespan.

5. Capacity

Ensure you know the desired flow rate and volume of nitrogen gas needed and select a nitrogen-making machine that can effectively meet the current and future nitrogen production demands.

The average capacity range of each machine type varies. Membrane nitrogen generators typically offer a lower to moderate nitrogen production capacity, ranging from approximately 100 to 5,000 standard cubic feet per hour (SCFH). PSA nitrogen generators provide a higher capacity, typically ranging from 5,000 to 10,000 of SCFH. Cryogenic nitrogen generators can produce larger volumes and offer higher capacities, ranging from 10,000 to 100,000 SCFH.

6. Material

Choose nitrogen-making machines with high-quality components capable of withstanding the chemical and physical properties of nitrogen gas. Look into actors such as resistance to corrosion, pressure, and temperature to ensure the longevity and optimal performance of the machine.

7. Size

Assess the dimensions and footprint of the nitrogen-making machine to determine if it can fit within the designated area of your facility. The membrane nitrogen generators are compact and typically range in size from approximately 2 feet by 2 feet to 5 feet by 5 feet. PSA nitrogen generators can vary in size but often have dimensions ranging from 4 feet by 4 feet to 10 feet by 10 feet. Cryogenic nitrogen generators are typically larger, with dimensions ranging from 8 feet by 8 feet to 15 feet by 15 feet or more.

Summary

When acquiring nitrogen-making machines, consider various factors, including nitrogen purity level, machine type, durability, price, capacity, material, and size. By thoroughly understanding your specific requirements and carefully evaluating these factors, you can make an informed decision and choose nitrogen-making machines that best suit your needs. To explore a diverse selection of nitrogen-making machines from different suppliers, consider visiting Alibaba.com.