Laser-cutting machines have become an integral tool in various industries, from automotive manufacturing to aerospace engineering. These machines use a high-powered laser beam to cut and shape a variety of materials with precision and efficiency. In recent years, there have been numerous advancements and innovations in the laser cutting machine market, making it an exciting and constantly evolving field. In this article, we will explore six of the latest trends in laser cutting technology and how you can use them to improve your production processes.

Table of Contents

Overview of the laser-cutting machine market

The top 6 trends for laser cutting machines

The bottom line

Overview of the laser cutting machine market

The global laser cutting machine market is expected to acquire a valuation of USD $5.96 billion, growing at a compound annual growth rate (CAGR) of 8.40% by 2030. This market growth is attributed to various factors. One of the main factors is the increasing demand for precision cutting in various industries, such as automotive, aerospace, and electronics. The adoption of advanced laser cutting technology in these industries has increased significantly in recent years due to its ability to provide high-quality cuts with minimal material waste and high efficiency.

Another factor driving the market growth of laser cutting machinery is the increasing adoption of automation and Industry 4.0 technologies, which has made laser cutting more efficient and cost-effective. Additionally, the growing demand for lightweight and high-strength materials, such as carbon fiber and aluminum alloys, has also contributed to the market growth of laser cutting machinery, as these materials require precise and accurate cutting techniques, which can be achieved using laser cutting technology.

North America and Europe are two of the leading regions in the global market for laser cutting machinery, due to the presence of advanced manufacturing industries and the adoption of advanced technologies in these regions. In addition, Asia-Pacific is another significant player in the global market for laser cutting machinery, due to the increasing demand for precision cutting in various industries, such as automotive and electronics, in countries like China and India.

The top 6 trends for laser cutting machines

1. Increased use of high-power output fiber lasers

The increased use of high-power output fiber lasers is maximizing efficiency in the laser machinery by allowing these machines to cut and process materials faster and more accurately than ever before.

Fiber lasers are able to produce high-energy laser beams that are able to cut through thick and dense materials with ease, making them ideal for a wide range of applications.

Some examples of laser machinery that use high-power output fiber lasers include:

- Industrial laser cutters: These machines use high-power output fiber lasers to cut through materials such as metal, plastic, and wood with precision and speed.

- Laser welding machines: These machines use high-power output fiber lasers to weld together metal components with a strong and seamless bond.

- Laser marking machines: These machines use high-power output fiber lasers to mark or engrave materials such as metal, plastic, and wood with a high degree of precision and clarity.

- Laser cleaning machines: These machines use high-power output fiber to remove thick coatings, rust, and other contaminants from a wide range of materials.

- Laser cladding machines: Also known as laser cladding, they deposit a thin layer of material onto a substrate to improve the surface properties of a material, such as wear resistance, corrosion resistance, and thermal conductivity.

2. Adoption of smart manufacturing technologies

Smart manufacturing technologies, such as automation, data analytics, and the Internet of Things (IoT), are helping to maximize efficiency in the laser machinery industry by allowing manufacturers to monitor and control their production processes more effectively.

Smart manufacturing technologies are typically adopted by big companies with more complex production processes, as they have the resources and infrastructure to implement and maintain these technologies. Retailers and wholesalers may also adopt these technologies to improve their supply chain management and reduce costs.

Some examples of smart manufacturing laser machinery include:

- Automated laser cutting machines: These machines use lasers to cut materials such as metal and plastic with precision, and can be programmed to operate automatically according to a predetermined set of instructions.

- Smart welding robots: These robots use lasers to weld materials together with precision, and can be programmed to operate automatically according to a predetermined set of instructions.

- IoT-enabled laser marking machines: These machines use lasers to mark materials such as metal and plastic with text, graphics, or other identifying information, and can be connected to the internet to allow for remote monitoring and control.

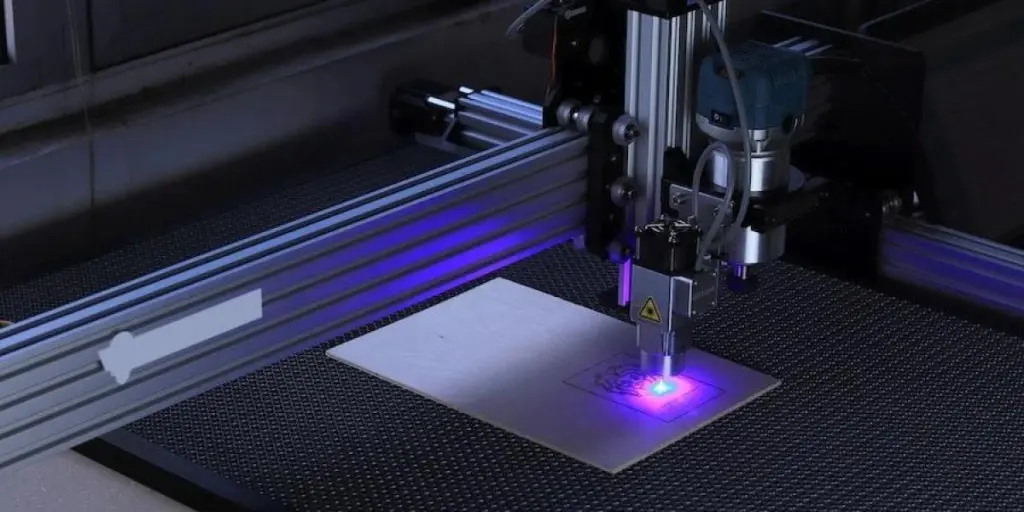

3. Development of hybrid laser cutting systems

The development of hybrid laser cutting systems is maximizing efficiency in the laser machinery industry by combining different laser technologies in a single machine. These systems use a variety of laser sources, such as ultrashort pulse lasers, to cut a wide range of materials with high precision and speed.

Hybrid laser cutting systems are also equipped with advanced features such as intelligent process control, automatic nozzle changing, and automatic material handling, which further increase efficiency and productivity.

Examples of hybrid laser cutting machines used in different applications include:

- Hybrid fiber laser: This type of hybrid laser combines a fiber laser with a CO2 laser, allowing it to cut a wide range of materials, including metals, plastics, and wood.

- Hybrid laser scanning system: This type of hybrid laser combines laser scanning technology with a CO2 laser, allowing it to cut intricate shapes and patterns with high precision and speed.

- Hybrid laser micro-machining system: This type of hybrid laser combines a laser with a micro-machining tool, allowing it to cut and drill very small and delicate parts with high precision.

4. Use of artificial intelligence and machine learning

The use of artificial intelligence (AI) and machine learning (ML) allows machines to analyze data and make decisions on their own, without the need for human intervention. This can help to improve the accuracy and speed of laser cutting and engraving operations, as well as reduce the risk of errors and downtime.

Examples of AI and machine learning laser machinery used in various industries include:

- Manufacturing: AI-powered laser cutting machines can analyze patterns in production data to optimize cutting paths, reduce waste, and improve efficiency.

- Healthcare: AI-powered laser scanners can analyze medical images to identify abnormalities and diagnose conditions.

- Defense: AI-powered laser weapons systems can analyze data from sensors and cameras to identify and track targets, and make decisions about when to fire.

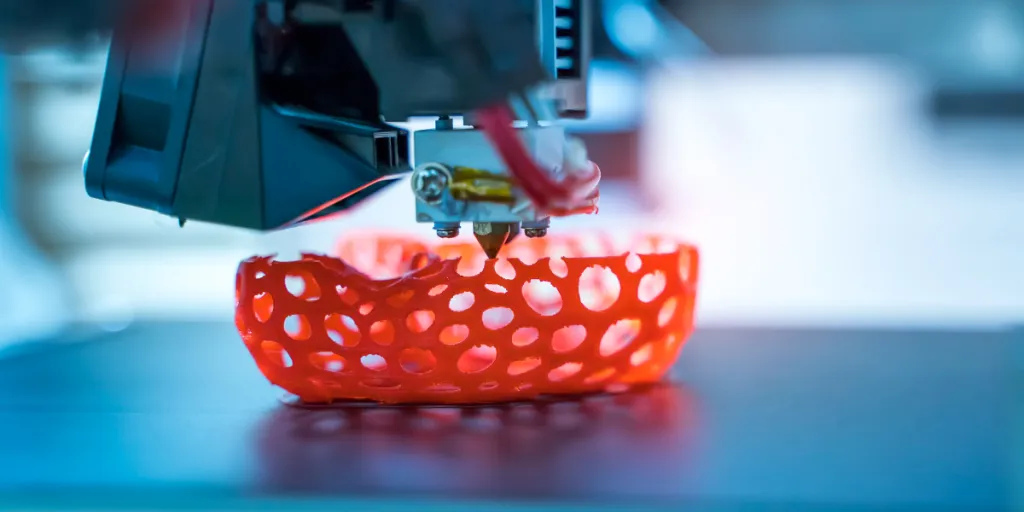

5. Increased use of 3D laser cutting

Increased use of 3D laser cutting allows manufacturers to produce complex and intricate parts and shapes with greater precision and speed. Manufacturers use 3D laser cutters to cut and shape materials such as metal, plastic, and wood according to a digital design.

Examples of 3D laser cutting machinery include:

- CO2 laser cutters: These machines use a CO2 laser to cut and engrave materials such as wood, plastic, and acrylic.

- Fiber laser cutters: These machines use a fiber laser to cut and engrave materials such as metal and plastic.

- Plasma cutters: These machines use plasma to cut and shape materials such as metal and aluminum.

6. Expanding applications of laser cutters

Manufacturers and users across various industries are now using laser cutters for a wider range of tasks, thus increasing their overall utilization power for more efficiency.

Some examples of expanding applications for laser cutters across different industries include:

- Cutting and engraving: Laser cutters are commonly used for cutting and engraving a wide range of materials, including wood, paper, plastic, metal, and glass. This allows businesses to create custom products, such as signs, labels, and gift items, with a high level of precision and efficiency.

- Marking and etching: Laser cutters can also be used for marking and etching materials, such as plastics, metals, and ceramics, with text or graphics. This allows businesses to create permanent, high-quality labels and markings on their products, which can help to improve branding and identification.

- Welding and brazing: Laser cutters can also be used for welding and brazing materials, such as metals, plastics, and composites. This allows businesses to quickly and accurately join materials together, improving the efficiency and speed of their manufacturing processes.

- Medical and dental applications: Laser cutters are also being used in the medical and dental industries for tasks such as laser surgery, laser-assisted dentistry, and laser-guided biopsy procedures. This allows for more precise and efficient treatments, with reduced risk of damage to surrounding tissue.

The bottom line

Businesses can use the above trends to boost their operations by adopting advanced laser-cutting technologies that can help to increase speed, accuracy, and efficiency. By staying up-to-date with the latest trends and technologies, you can stay competitive and position yourself for growth in the evolving market.