Knitting machines have been used for years to knit fabrics. Most of the clothes we wear are made using knitting machines. Many of these knitting machines are available in the market right now and have different capabilities. Before deciding on the knitting machines you are going to put your money into, it is wise to know the different types available and their capabilities.

In this article, we are going to focus on how to select suitable knitting machines and the market share of these machines. Also, we will discuss the different types of knitting machines available in the market as well as their pros and cons.

Table of Contents

Overview of the knitting machines market

Structure of knitting machines

Types of knitting machines

How to select suitable knitting machines

Conclusion

Overview of the knitting machines market

The international knitting machinery market is segmented by machine types, knit types, applications, and geography. Considering machine types, they include the warp and weft industrial knitting machines. The various knit types are performed by single-knit and double-knit industrial knitting machines. Some of the applications of knitting include medical textiles, home & furniture textiles, and automotive & transportation textiles.

According to Fact.MR, the global knitting machinery market is currently valued at USD 1.26 billion. It is expected to expand and reach USD 1.78 billion by 2032, representing a compound annual growth rate (CAGR) of 3.5% during the forecast period. The rise in demand is driven by the increased use of circular knitting equipment that produces quality fabrics at high speeds.

Regionally, Europe accounts for a 24.1% share of the market owing to the demand for localized textiles and the rapid adoption of advanced technology in the knitting industry. North America contributes about 21.9% to driving the industrial knitting machinery market as a result of increased urbanization and the presence of significant knitting equipment manufacturers.

Structure of knitting machines

There exist numerous types of knitting machines that range from the simple spool or board templates without moving parts to complex machines controlled by electronics. They all produce different kinds of knitted fabrics that are either flat or tubular based on the degrees of complexity.

The basic components of a knitting machine and their functions include:

– Creel: It is the holder of the cone for feeding the yarn to the feeder.

– Feeder: Yarn is fed through the feeder depending on the design of the fabric.

– VDQ pulley: It controls the fabric’s stitch length.

– Guide: This supporting element is used to guide the yarn.

– Sensor: It is an automatic controlling system that stops the knitting process in case the yarn breaks or any other problem occurs.

– Cylinder: It is the main part of a knitting machine and carries needles, cam, sinkers, and other components.

– Spreader: It is utilized to spread the knitted fabric before the roller take-up. It is adjusted whether the knit fabrics are the open type or tubular.

Types of knitting machines

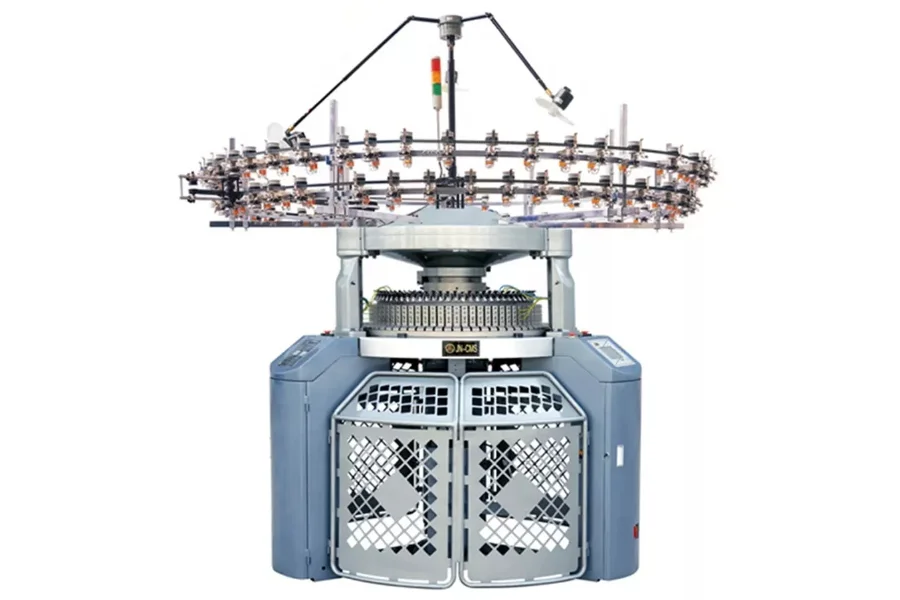

1. Weft knitting machines

Weft knitting machines are utilized to make weft knitted garments using a single yarn. In this technique, the looms are horizontally knitted in a circular way from the left of the fabric to the right. The weft knits are made out of yarn being fed into the circular knitting machine needles. The basic stitches in weft knitting include face loops, float stitches, reverse loops, and tuck stitches.

Below are the various types of weft knitting:

– Double knit

– Jersey

– Circular knit

– Cable knit

– Fair isle

Pros

– It is cost-efficient compared to warp knitting as it produces narrow fabrics.

– Weft knitted fabrics are elastic and comfortable to wear.

– Weft knitting produces items that do not fray easily.

Cons

– Weft knitted fabrics shrink easily, unravel when cut, and have the tendency to curl at the edges.

– Weft knitted materials can be laborious to dry clean and press.

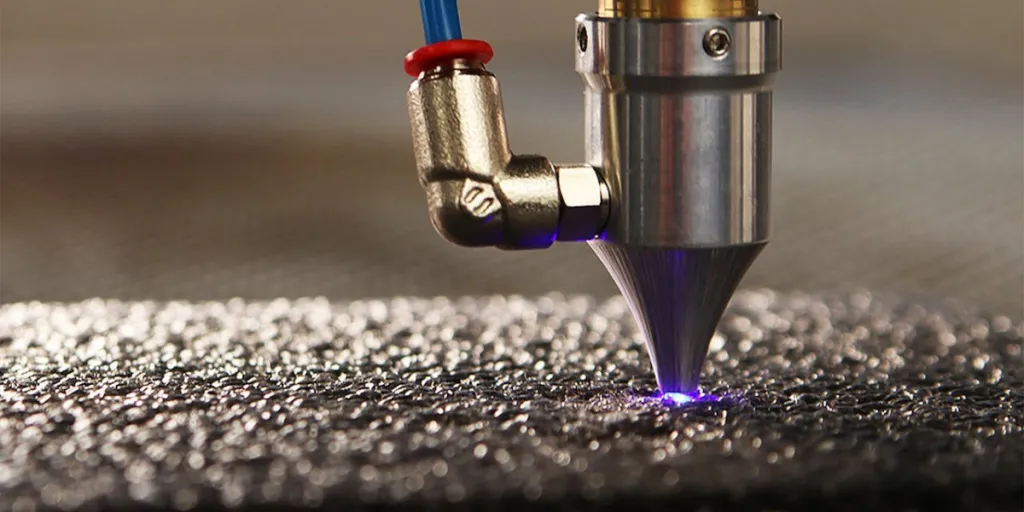

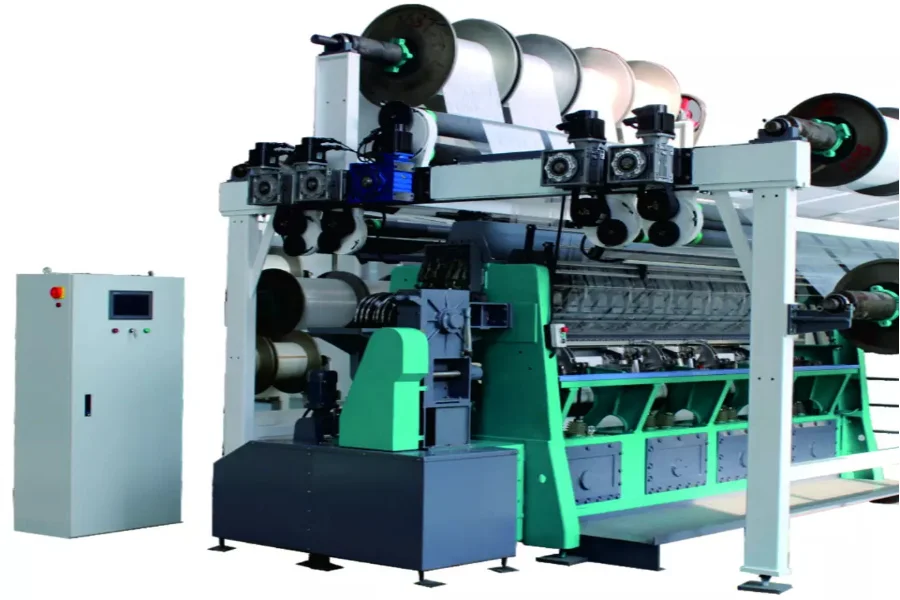

2. Warp knitting machines

Warp knitting machines are used to knit in zigzag patterns along the fabrics. The knits are run through the adjacent columns or wales. In other terms, it is a loop-forming technique where the single set of yarn being fed into the knitting zone is parallel to the fabric selvage. Vertical loops are formed in one course and the yarn moves diagonally to knit the next course. There are three types of warp, which include bow, cup, and crook.

Pros

– It can create three-dimensional structures that are knitted on a double needle bar raschel.

– There is a variety of fabric instructions.

– It achieves higher productivity rates.

– It offers large working widths.

– There is a low-stress rate on the used yarn to allow for use of fibers like aramid, glass, and carbon.

Cons

– The material knitted on a warp is raw thus it is difficult to work with.

– In case of malfunctions, it takes a lot of time to repair, and warp knitting can be hard when done by hand.

– To produce a sturdy item, the yarn used has to be fine and be used in the right count thus the process is cumbersome.

How to select suitable knitting machines

1. Machine gauge

Considering the machine gauge, there are mid-gauge, standard gauge, and chunky gauge knitting machine types. Mid-gauge machines have about 6, 6.5, and 7 mm between each needle. They are suitable when the buyer is short of time and intends to knit their clothes, for instance hand-knit yarns and patterns. To achieve finer knit garments, a buyer would opt for a standard gauge machine that has 4.5 mm between each needle. The chunky gauges have around 9 mm between each needle and are suited to knit thick and heavyweight fabrics that require surface patterning.

2. Cost

The cost of knitting machines varies considerably depending on whether they are new or second-hand. A used machine should be in proper working condition with fully functional components. If acquiring a second-hand machine, also consider maintenance costs including repairs and part replacements. As for new machines, take into account the initial price and the cost of its peripheral devices. Apart from the budget, the final decision will be determined by the kind of projects a buyer has.

3. Patterning method

Buyers should understand that various patterning methods are available based on the gauges of the knitting machines. Firstly, a machine should have the capability to easily and quickly create lace, designs, and textured patterns. Many automatic patterning machines can produce several decorative patterns like tuck, isolation, and knit-in. The older single-bed equipment had punch-card attachments and sets of pre-punched cards. Most recent electronic knitting machines have around 700 built-in designs. Additionally, they can transfer about 200 different stitches from one bed to the other depending on the model.

4. Yarn

There are various types of yarn used based on the capabilities of the knitting machines. Buyers need to know the yarn sizes so that they can easily choose the suitable range for their knitting machines. Some of the available yarns include lace-weight yarn, medium yarn, bulky & and super bulky yarn, and super fine or light yan. Fingering, sport, worsted weight, and bulky yarns can be used on knitting machines based on the type of knitted fabrics. Also, large yarn should not be used on fine-gauge knitting machines to avoid wastage when the carriage jams the yarn.

5. Capability

Capability includes the range of a knitting machine’s optional accessories, patterns, stitches, and yarns used. A typical knitting machine has about 150 to 220 latch hooks in the machine bed depending on the gauge type. Some of the optional accessories available for knitting machines include the ribber, motors, lace carriage, garter carriage, cast-off linker, transfer carriage, intarsia carriage, garter bar, and color changer. All these features contribute to the capabilities of knitting machines and provide a comparative advantage.

6. Type

This describes the machine design, which includes the warp and weft knitting machines. In warp knitting, all the elements of a certain type—for instance sinkers, needles, or guides of one guide bar—act as a single unit. They are easily fitted into and controlled from one element bar. As a result, each guide bar needs the same warp-yarn tension and feed rate. On the other hand, weft knitting machines have a limited count of yarn feed positions. Therefore, they require different rates of yarn feed supplied from cones. The needles knit in a serial formation thus the machine allows for rearranging of the frame for the circular or straight needle bed based on the requirements.

7. Speed

Generally, the speed of knitting machines varies according to the gauge sizes, the number of feeders, and the type of yarn being run. On average, the optimum speed of knitting machines is 40 rotations per minute. With this speed, a typical modern knitting machine can achieve a range of 600 to 1200 stitches per minute. Specifically, the speed of a circular knitting machine can be expressed based on the machine revolutions per minute and the circumferential speed in meters per second. The circumferential speed is around 1.5 m/sec and 2 m/sec for higher speeds machines.

Conclusion

In the long run, it really comes down to what suits buyers’ needs or the projects they intend to complete. The above guide outlines key considerations to avoid ending up with knitting machines that do not match the buyers’ production lines. For home-based knitting, a simple plastic machine would suffice. On the other hand, for heavier and bulkier production, computerized knitting machines would be most preferred. Under various circumstances, these machines have benefits and downsides. Either way, to find quality and high-performance knitting machines, visit Alibaba.com.