Motorcycle oil filters are essential for optimizing engine performance, extending lifespan, and adhering to strict emission standards. As demand for motorcycles grows, understanding the evolving filter market becomes crucial for industry professionals seeking high-quality, reliable solutions.

This article examines key market trends, highlights the unique features of various filter types, and provides data-driven insights to support informed purchasing decisions. By focusing on advanced technologies and practical selection criteria, it offers valuable guidance for meeting the performance and compliance needs of modern motorcycles. Stay ahead of the curve with strategies tailored to enhance engine efficiency and longevity.

Table of Contents

A thriving market: Motorcycle oil filters in numbers

Market size and growth

Regional dominance and driving forces

Aftermarket opportunities

Exploring filter types: From cellulose to cutting-edge synthetic media

1. Paper filters: Economical and efficient filtration

2. Synthetic filters: Superior technology for high-performance demands

3. Fiberglass and metal filters: Balancing durability with performance

4. Centrifugal and magnetic filters: Innovative contaminant management

Smart buying: Key factors when selecting the perfect oil filter

Filtration media: Balancing durability and performance

Fit and compatibility: Avoiding mismatched filters

Micron rating and flow capacity: Striking the right balance

Durability in extreme conditions

Conclusion

A thriving market: Motorcycle oil filters in numbers

Market size and growth

The global motorcycle oil filter market is projected to grow at a CAGR of 5.1%, reaching an estimated $6.36 billion by 2034, according to Fact.MR. This growth is fueled by increasing demand for motorcycle filters that enhance engine performance and meet stringent emission regulations. The rise in the adoption of motorcycles for daily transportation and recreational use has significantly contributed to the market’s expansion.

Regional dominance and driving forces

East Asia is anticipated to dominate the global market, accounting for 36.5% of market share by 2024, as highlighted by Fact.MR. This growth is driven by the high popularity of high-performance motorcycles and a surge in aftermarket demand for older motorcycles. Additionally, increasing government regulations on emissions and the need for fuel efficiency are further boosting the demand for advanced filter technologies.

Aftermarket opportunities

The rising number of older motorcycles globally has resulted in growing opportunities within the aftermarket segment. Replacement filters are increasingly required for maintaining aged vehicles, which drives steady demand. The focus on enhancing engine longevity and compliance with environmental standards positions aftermarket sales as a lucrative segment in the global market landscape.

Exploring filter types: From cellulose to cutting-edge synthetic media

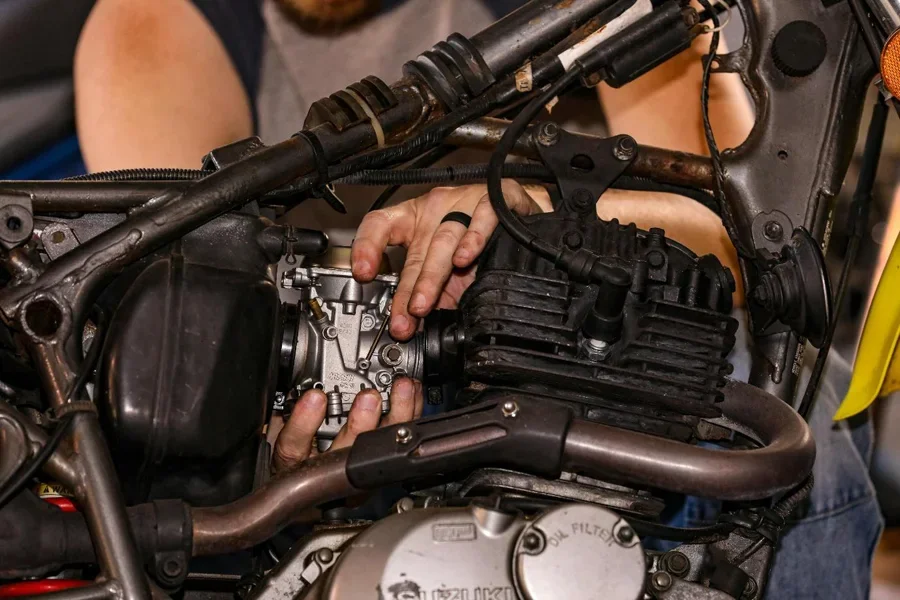

1. Paper filters: Economical and efficient filtration

Paper filters are constructed using cellulose or cotton fibers, often treated with resin to enhance durability and filtration efficiency. These filters typically capture particles as small as 25-30 microns, making them effective for regular engine protection. Their pleated design maximizes surface area, allowing for greater oil flow and contaminant retention. However, their limited structural strength and susceptibility to clogging under heavy contaminant loads reduce their lifespan, necessitating replacements every 3,000 to 5,000 miles in standard applications.

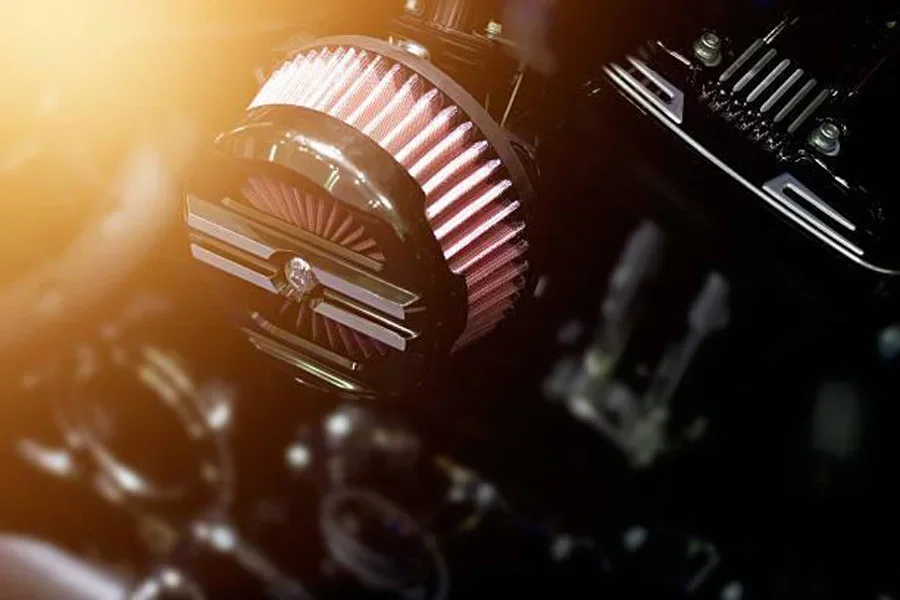

2. Synthetic filters: Superior technology for high-performance demands

Synthetic filters employ engineered fibers, such as polyester or glass blends, capable of filtering particles as small as 5-10 microns, offering significantly finer filtration compared to paper filters. These filters also provide consistent flow rates under extreme temperatures and pressures, making them suitable for high-performance motorcycles. Synthetic media are often layered in multiple strata, ensuring optimal oil distribution and preventing bypass under high flow conditions. Their extended service life—often lasting up to 10,000 miles or more—reduces maintenance frequency, contributing to overall cost efficiency for performance-oriented applications.

3. Fiberglass and metal filters: Balancing durability with performance

Fiberglass filters utilize tightly woven glass fibers, achieving high contaminant capacity while maintaining flow rates. These filters are particularly effective in capturing ultra-fine particles in high-stress conditions. Metal filters, constructed from perforated steel or aluminum, are designed for maximum durability and are often reusable, withstanding extreme heat and pressure. Their typical applications include off-road or racing motorcycles, where robust design is critical. Metal filters usually feature micron ratings of 40 or higher, trading filtration fineness for flow optimization, which is ideal for engines requiring rapid lubrication under heavy loads.

4. Centrifugal and magnetic filters: Innovative contaminant management

Centrifugal filters rely on rotational force, achieving separation by directing contaminants outward toward the walls of a spinning drum. These filters operate without media, which reduces the need for frequent replacements. They are capable of handling heavy contaminant loads, often processing oils in engines exposed to harsh conditions. Magnetic filters, by contrast, employ strong magnetic fields to attract and immobilize ferrous particles. These filters are often combined with secondary filtration systems to enhance overall contaminant control. Both types are known for their high tolerance to repeated use and ability to improve oil cleanliness in unique operational environments.

Smart buying: Key factors when selecting the perfect oil filter

Filtration media: Balancing durability and performance

Selecting the appropriate filtration media is essential for ensuring both engine protection and cost-effectiveness. Cellulose media are suitable for basic applications, capturing particles in the 25-30 micron range but requiring more frequent replacement due to limited contaminant capacity. Synthetic media, constructed from engineered fibers like polyester or glass, offer superior filtration down to 5-10 microns, with enhanced oil flow and durability under extreme conditions. Micro-glass media, the most advanced option, utilizes ultra-thin glass fibers for exceptional particle capture and extended service intervals, often up to 10,000 miles or more, making them ideal for high-performance motorcycles.

Fit and compatibility: Avoiding mismatched filters

The fit of the oil filter is critical to ensuring proper function and avoiding potential engine damage. Each motorcycle model requires a specific filter design, accounting for variables like thread size, gasket dimensions, and bypass valve specifications. Using a mismatched filter can lead to oil leaks or restricted flow, negatively impacting engine performance. Cross-referencing the manufacturer’s specifications with the filter’s design ensures compatibility and optimal performance, particularly for aftermarket products or upgrades.

Micron rating and flow capacity: Striking the right balance

Micron ratings indicate the smallest particle size a filter can capture, with lower ratings corresponding to finer filtration. While a rating of 10 microns or below is preferred for high-performance engines, it is equally important to consider flow capacity. Filters with overly fine media can restrict oil flow, especially in high-pressure systems. Multi-layered media or advanced designs often mitigate this issue, maintaining efficient flow without compromising filtration, crucial for engines operating at high RPMs or in extreme environments.

Durability in extreme conditions

Oil filters designed for extreme conditions feature innovations like anti-drainback valves to prevent oil loss during shutdowns and robust housings to withstand high pressures and temperatures. These features are particularly valuable in cold climates, where oil viscosity increases, and in motorcycles subject to aggressive riding or heavy loads. Filters engineered for endurance racing or off-road use often include reinforced cases and advanced bypass systems to ensure continuous lubrication, even under adverse conditions.

Conclusion

Selecting an appropriate motorcycle oil filter is essential for maintaining engine efficiency and durability. By evaluating market trends, understanding the technical distinctions between filter types, and prioritizing compatibility and performance features, businesses can ensure reliable and cost-effective solutions for their needs. A focus on quality and adherence to recommended maintenance schedules further supports engine longevity and compliance with operational demands.