Oxygen sensors (O2 sensors) are crucial in ensuring a vehicle’s optimal performance. They monitor the amount of unburned oxygen in the exhaust and produce a signal that varies depending on the oxygen levels. With more people buying vehicles, there is a high demand for vehicle parts and accessories like O2 sensor sockets to replace the oxygen sensors when they are damaged.

Small businesses and retailers should take advantage of this demand to stock all types of oxygen sensor sockets, helping customers change their O2 sensors when necessary.

This article will look at the different O2 sensor sockets you need in your inventory, the O2 sensor tool market, and how to change an O2 sensor.

Table of Contents

Market overview

Overview of the O2 sensor socket

Types of O2 sensor sockets

Choosing the right oxygen sensor sockets

Socket design

Material

Drive size

Depth and offset

How to use an O2 sensor socket

Summing up

Market overview

According to Market Research Future, the oxygen sensor market was valued at USD 7.16 billion in 2025 and is expected to grow at a compound annual growth rate (CAGR) of 4.12% to reach USD 10.29 billion by 2034. This shows a growing demand for oxygen sensors, which translates to a demand for oxygen sensor sockets and other tools.

This demand is attributed to the stringent emission regulations to reduce air pollution and mitigate the effects of climate change. Oxygen sensor sockets ensure drivers have the right tools to change their O2 sensors to meet the emission standards.

The increase in vehicle production has also led to increasing demand for O2 sensor sockets and sensor wrenches, as people need to change their sensors when they are faulty.

Overview of the O2 sensor socket

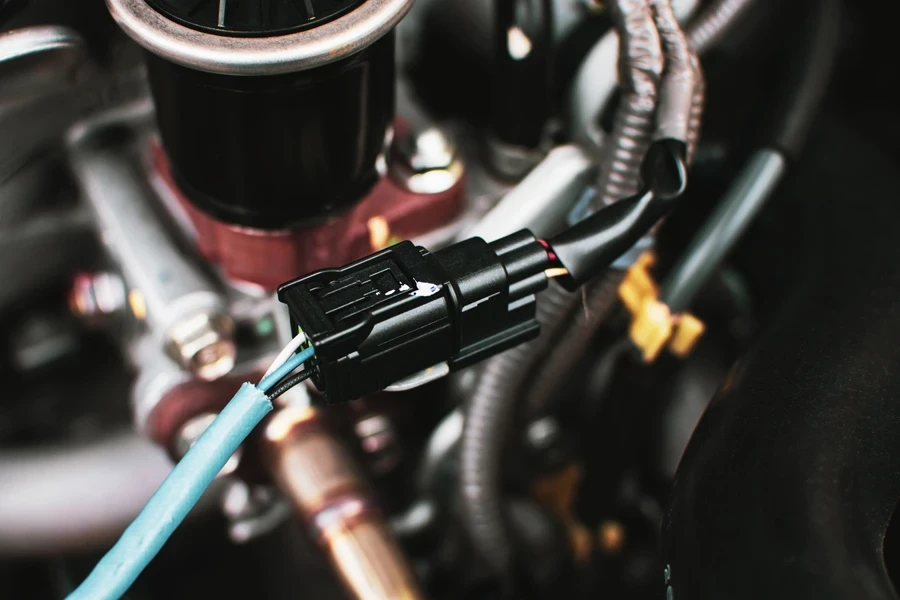

An oxygen sensor socket is a specialized tool used to install and remove an O2 sensor in a vehicle’s exhaust system. Unlike regular sockets, an oxygen sensor socket has a cutout on one side to allow the sensor wiring to pass through, so one doesn’t damage the sensor or the wires when installing or removing the sensor.

O2 sensor sockets are typically 22mm or ⅞ inches, but they come in different sizes to fit different vehicle models. They are made of durable materials like chrome vanadium steel, and some have angled designs to help reach sensors in tight spaces.

Types of O2 sensor sockets

Some of the types of sockets you should have in your inventory include:

- Standard O2 sensor sockets: These are the most common and work well with most vehicles. Standard O2 sensor sockets have a slot for the sensor wires and a hexagonal design for a secure grip.

- Offset or angled sockets: These are designed for O2 sensors in tight, hard-to-reach spaces. Offset sensor sockets have angled heads that allow one to access sensors in tight spaces or near other components.

- Universal and vehicle-specific sockets: While most O2 sensor sockets are universal, some are made for specific vehicles. If one works on different vehicles, they should get a universal sensor socket.

- Impact sockets: These heavy-duty sensor sockets are ideal for heavily corroded sensors and are made for use with impact wrenches.

Choosing the right oxygen sensor sockets

Some customers may find it challenging to find the right sensor sockets for their vehicles. This is where you come in. Your insights will help your customers get the right O2 sockets.

Socket design

One of the main things customers need to look at is the socket design. There are two main designs: the slotted socket, which has a cutout on one side to allow the sensor wires to pass through, and the crowfoot wrench, which can be used in tight spaces.

The slotted socket is the most common and user-friendly for beginners, but the clawfoot sensor socket works best in tight spaces. Ensure the customer chooses the right socket that fits well and allows sensor engagement without losing the grip.

Material

The quality of the materials used to make an O2 sensor tool affects its performance and durability. Ensure you stock quality sensor sockets. The highest-quality are made of chrome-vanadium steel or steel alloys. They are strong and corrosion-resistant.

Drive size

O2 sensor sockets have different drive sizes, mainly ⅜ inches or ½ inches, to match wrenches or ratchets. Customers should ensure the drive they buy fits the tools they already have. The sockets they buy should also fit the sensors correctly. If they are too tight, they will not fit over the sensor; if they are too loose, they will risk stripping it.

Depth and offset

Customers should get sensor sockets with the right depth and offset. If the offset is off, they risk damaging the nearby parts. If the socket is too deep, it will not have enough leverage on the sensor; if it’s too shallow, it won’t engage with the sensor. They should buy O2 sensor sockets that reach the sensor comfortably and aren’t unwieldy in tight spaces.

How to use an O2 sensor socket

When a check engine light comes on, there may be a lot going on, and one cause is a bad O2 sensor. A faulty or damaged O2 sensor needs replacement to limit emissions and improve the vehicle’s performance.

Here are a few steps to use an O2 sensor socket to replace an O2 sensor:

- Locate the O2 sensor: In most vehicles, it is in the catalytic converter. There are typically two O2 sensors, one upstream and one downstream. To find the exact location, consult the vehicle’s manual.

- Prepare the tools: Ensure you have an O2 sensor socket, a ratchet, and an extension bar if the sensor is in a tight spot and hard to reach.

- Loosen the sensor: Attach the socket to the sensor and slowly turn it counterclockwise to loosen it. If the sensor is stuck, penetrating oil like WD-40 can break the corrosion.

- Remove the sensor: When loosened, unscrew it by hand and mind the wiring.

- Install the new sensor: apply anti-seize compound on the sensor threads to aid future removal if it’s not pretreated. Screw it in by hand and use the sensor socket to tighten it and avoid over-tightening, then plug in the sensor connector and test the vehicle.

After use, clean the sensor socket and store it properly in a toolbox to avoid loss or misplacement. When the socket slots and edges get worn out, replace them to prevent stripping O2 sensors when installing them.

Summing up

O2 sensor sockets are crucial in removing and installing O2 sensors in a vehicle’s exhaust system. Customers should invest in the correct O2 sensor sockets to get the job done without frustrations and save time.

As a small business and retailer, you should have different types of O2 sensor tools in your inventory to cater to different customer needs. You should also educate your customers on the proper use and maintenance of the tools. This will keep you ahead of your competitors and earn you loyal customers.