The term “dump months” is a film industry jargon that links to lower film responsive expectations, particularly in the first two months of the year. Conversely, the opposite of dump months would be the peak release periods, during which studios schedule their most anticipated and high-budget films to capitalize on increased audience attendance.

In fact, peak season is a phenomenon that exists in almost all industries. In the logistics and shipping industry, for instance, the impact of peak seasons can be even more pronounced. Unlike the film industry, where peak seasons are relatively predictable, logistics companies must handle a wide array of products with multiple overlapping peak seasons, amplifying the effects of peak season in logistics. Continue reading to find out what’s considered a peak season in logistics, its typical periods throughout the year, and how to manage the demands and challenges of peak season.

Table of Contents

What is peak season?

Peak season throughout the year

Key challenges of peak season

Strategies for managing peak season

Traversing the peaks

What is peak season?

The term “peak season” is indeed rather self-explanatory and straightforward: it simply refers to the busiest period of the year in any industry, product, or service sale. It is practically applicable to anything that is seasonally driven, in high demand, or limited by capacity since these items are more susceptible to the effects of the peak season cycle.

By the same extension, peak season in logistics represents the busiest time of the year, characterized by a significant surge in demand for transportation services. More often than not, these peak seasons are predictable based on specific events and historical patterns. To identify these peak periods throughout the year, one must first understand the factors contributing to them. The most typical driver of a peak season in delivery services is consumer demand. As such, virtually any marketing strategies or societal influences that boost significant consumer spending can trigger a peak season.

Various holiday seasons and festivals, for instance, are among the prime periods that various businesses launch promotions and marketing activities to stimulate seasonal purchasing behavior. During such times, consumers also tend to respond more enthusiastically to these promotional efforts in line with the societal influence that often associates holiday seasons with gatherings and gift-sharing activities, naturally leading to increased demand for a wide range of products. It’s worth noting that holiday seasons here not only refer to public holidays but also include school holidays when parents are more receptive to various back-to-school offers.

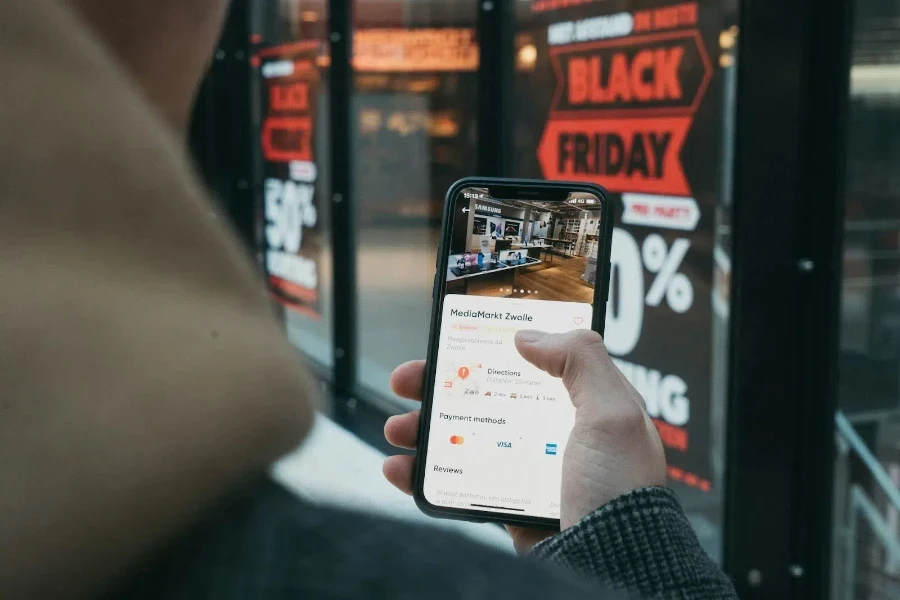

In addition to traditional holidays and festive seasons, another significant type of seasonal global event—often seen as modern-day non-official “festive days”— also contributes to extending the global peak season in logistics. These events are primarily driven by the expansion of ecommerce, supported by various offline retail offers. For instance, Black Friday and Cyber Monday are prominent examples of “worldwide shopping festivals” that initially involved primarily U.S. retailers but have since spread to global retailers and numerous ecommerce stores.

At the same time, the fierce competition and growing presence of various social marketing and ecommerce are also among the significant factors that further bolster consumer demand during peak season. Coupled with the rise of omnichannel strategies that seamlessly integrate both online and offline retail channels, these approaches add a new dimension to peak season logistics with their versatility and complexity.

Finally, apart from relatively predictable seasonal peak periods, certain sudden or unpredictable global events can also give rise to unexpected peak seasons due to capacity constraints or a sudden surge in demand driven by fears of stockouts. Such unforeseen peak seasons are often driven by crises such as wars and natural disasters, which may include both actual physical wars or symbolic trade disputes.

Peak season throughout the year

Chinese New Year

Long dubbed the largest yearly migration on earth, the Chinese New Year (CNY) is a major driver of peak season in the shipping industry. This is largely due to the traditionally weeks-long holiday period, which leads to the closure of almost all production lines and factories in China. Since China earned its status as the “world’s factory” after joining the World Trade Organization (WTO) in December 2001 and is currently the world’s largest exporting country, the impact of Chinese New Year on peak season in logistics is undoubtedly significant.

The impact and repercussions of the Chinese New Year are so far-reaching and extensive that not only does nearly all business activity in China halt and cause disruptions in transportation networks during CNY, but the aftereffects can also extend long beyond the holiday period. Many factory and port workers may take up to six weeks to resume their normal operations due to the long traveling journey back from their hometown. Many also often make use of the long holiday to replan their career path and seek new job opportunities, which can delay the return to full productivity.

In light of these issues, out of fear of delays, many shippers rush to ship their goods before the CNY shutdowns, causing an undesirable pre-holiday surge in shipping demand. The worst part is that the impact of CNY is not confined to China or its direct trade partners; it reverberates worldwide due to globalization and the interdependence of global logistics.

Summer holidays

As we move from the early part of the year to the middle, the logistics industry typically faces the next peak season during the summer holiday period. This is due to two main factors: the vacation and travel period that sees a rise in demand for supplies catering to the influx of tourists, and increased demand for goods related to seasonal activities, such as outdoor events and the related home and garden improvement needs.

The high demand for seasonal goods, coupled with the vacation season, can cause congestion in logistics networks and disruptions in the shipping industry workforce. To be precise, it’s equally important to note that the summer holiday season is July-August in the Northern Hemisphere but December-January in the Southern Hemisphere.

Global shopping events

As we approach year-end, Black Friday and Cyber Monday—the global shopping events following Thanksgiving in the U.S., which typically occur between late November and early December—mark the next peak season in the worldwide shipping industry.

These events, driven by significant promotions and discounts offered by various offline and online retailers worldwide, lead to a surge in consumer demand, resulting in increased freight volume and congestion. In fact, to manage the potential spike in demand, many brick-and-mortar retailers as well as ecommerce platforms begin preparing shipments as early as two months prior to these events to meet anticipated needs.

Year-end holidays

Finally, the long holiday season during Christmas and New Year, normally marked by a minimum 1-2 week vacation period, marks the final peak season in logistics operations throughout the year. This is not only due to the significant increase in retail activity, both online and offline, but also due to the reduced workforce in the worldwide shipping industry, as many employees take extended vacations. On top of these, the severe weather conditions often experienced during year-end can further exacerbate the peak season, leading to additional delays and logistical challenges.

Key challenges of peak season

The consumer behaviors that have led to an extended peak period in logistics nowadays reflect two significant challenges: rising freight rates and capacity limitations. Indeed, the peak season in logistics has been getting significantly earlier, thanks to the convenience provided by ecommerce shopping, which allows consumers who fear the risks of out-of-stock issues and increased costs, particularly shipping rates during peak season, to bring forward their holiday shopping schedules to avoid these problems.

Simultaneously, the significant surge in ecommerce orders and their preference for expedited shipping, which emphasizes faster delivery times and expanded last-mile delivery options, has led to unpredictable order volumes. This further strains the typically already congested and overwhelmed warehouses during peak seasons.

All these issues can further intensify challenges in operational and resource management. During peak season, companies are often compelled to deal with more complex operational challenges due to the unavoidable need for more vehicles, workers, and resources. Long factory holidays further compound these operational issues, leading to inevitable disruptions in inventory replenishment and difficulties in stock control.

Reverse logistics and returns management are two other major challenges that may not seem to happen immediately during peak season but can be equally challenging. For example, during the 2023 U.S. holiday season, studies indicated that about 15.4% of purchased items were returned, amounting to a staggering $150 billion. What’s more troubling is that approximately $24.5 billion of these returns were likely due to fraudulent claims.

Strategies for managing peak season

In one of his bestselling books, John C. Maxwell once highlighted the key difference between being proactive and reactive: “If you’re proactive, you focus on preparing. If you’re reactive, you end up focusing on repairing.” Indeed, proactive planning including early shipping capacity booking and potential contingency plan draftings are all essential preparations to navigate various peak season challenges.

Meanwhile, businesses should also allocate extra budget and ensure a thorough understanding of all necessary regulations to maintain compliance. These preparations are crucial in managing higher shipping rates and the potentially more complex customs requirements that often arise due to longer transit points in peak season.

It’s also essential to stay flexible and be readily adaptable to adopt various shipping options and routings. Longer transit time options may be useful to avoid overbooking and bottleneck issues on popular routes. Concurrently, thorough planning should also consider buffer and safety stocks for robust inventory management.

Check through any historical data to develop a more effective and adaptable strategy, which can be particularly useful for routes and schedules optimization planning, since these processes often follow some similar previous patterns. Furthermore, utilizing advanced technologies like AI and machine learning tools can help to enhance the accuracy of statistical forecasts while also promoting automation, which is valuable in managing high shipping volume and complex logistics during peak season.

Finally, aside from inventory management and advanced shipment planning, partnering with experienced and seasoned shipping providers, and maintaining open communication with both customers and suppliers are also crucial to gain valuable insights and expertise to ensure a well-coordinated operation together.

Traversing the peaks

Peak season in the logistics industry represents some of the busiest periods that see a significant increase in transportation demand. To effectively manage and navigate peak season in logistics, early planning is essential. Partnering with experienced freight providers and maintaining open communication with both customers and suppliers are also crucial for fostering more synchronized operations. The adoption of advanced technologies like AI and machine learning can further assist in more accurate demand forecasts and enhance automation in logistics operations.

Explore advanced logistics insights and professional wholesale business strategies at Alibaba.com Reads. Launch a transformative knowledge search journey today by exploring our platform regularly to stay updated with the latest trends in wholesale business and logistics.