Table of Contents

1. Introduction

2. Understanding brake calipers: types and applications

3. Market insights for brake calipers in 2025

4. Key factors to consider when choosing brake calipers

5. Top brake caliper models and their features

6. Conclusion

Introduction

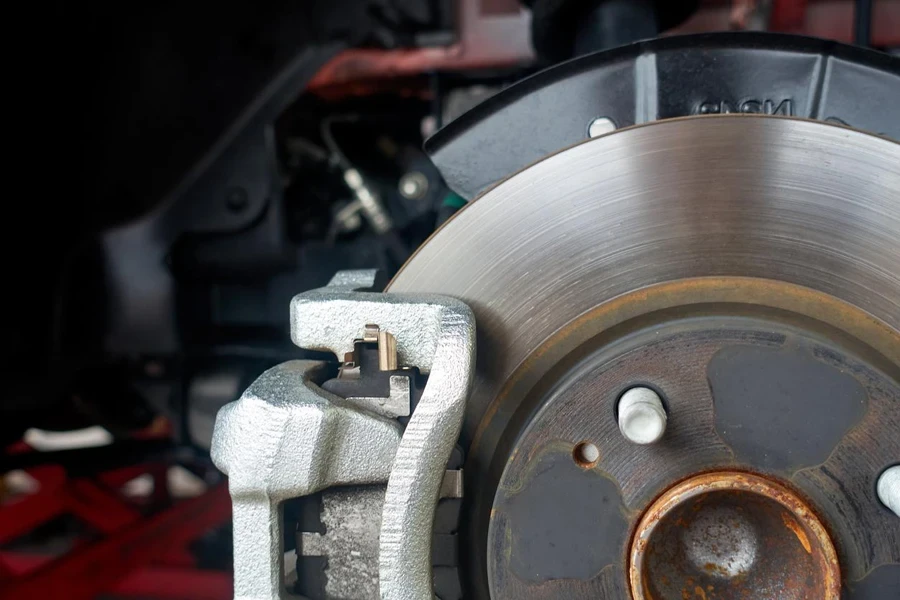

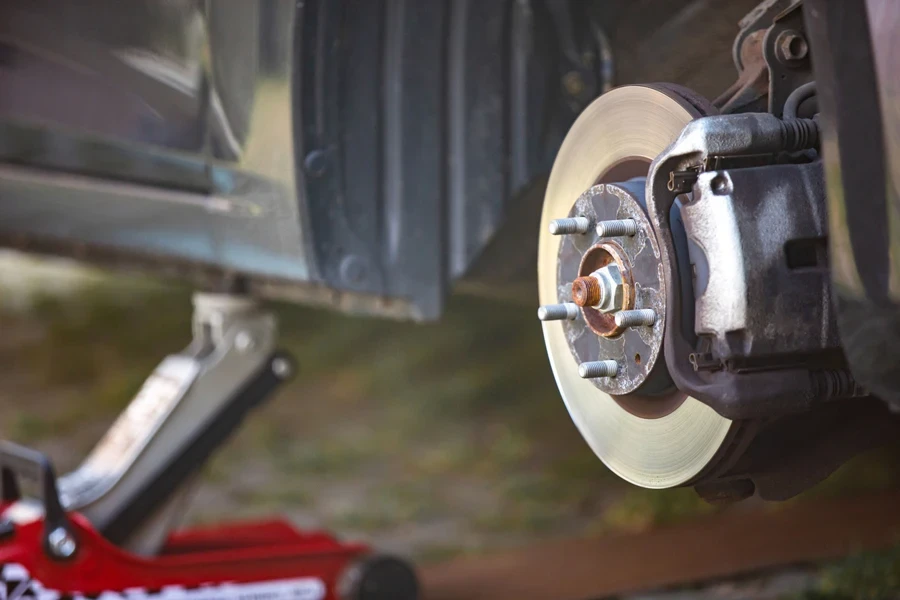

Brake calipers play a crucial role in today’s braking systems by translating hydraulic pressure into mechanical force. They press brake pads against rotors and create the necessary friction for slowing or stopping a vehicle effectively and safely. These calipers are used across various types of vehicles, such as passenger cars for daily use, heavy-duty trucks, and high-performance vehicles. In recent years, improvements in design and materials have enhanced the performance of calipers in managing heat dissipation and resisting corrosion over extended periods, helping meet the requirements of both regular and high-performance uses. Choosing the appropriate brake calipers is crucial to ensuring top-notch braking capabilities across different situations as cars become more sophisticated.

Understanding brake calipers: types and applications

Brake calipers play a key role in car brakes by turning hydraulic pressure into mechanical force to slow down or stop the wheels from turning effectively and safely. Choosing the right caliper type is key for top performance and safety.

Floating vs. fixed calipers

Floating calipers are often found in passenger cars for their affordability and simplicity. They contain pistons at one side of the rotor, pushing the inner brake pad against the disc. The caliper then slides and engages the outer pad to contact with the rotor utilizing guide pins. This design is suitable for general driving conditions but may not provide the consistent pressure distribution required for high-performance applications.

Fixed calipers are secure and feature pistons positioned symmetrically around the rotor to ensure even pressure distribution over the brake pads. This helps to improve braking effectiveness and performance enhancement in high-performance and heavy-duty vehicles where top-notch braking is crucial. They tend to be pricier and intricate compared to floating calipers.

Multi-piston calipers

The number of pistons within a caliper plays a role in influencing braking effectiveness. Calipers equipped with many pistons, ranging from six or more pistons, deliver increased clamping force and better modulation than single-piston arrangements. This leads to better braking capability and superior heat dispersal, which helps mitigate the chances of brake fade when under prolonged usage. These calipers are frequently utilized in high-performance vehicles and situations demanding robust braking capabilities.

Specialized calipers for unique conditions

In some driving situations, special caliper designs are needed. The sliding calipers are light and affordable, like floating calipers, making them ideal for compact cars that benefit from weight reduction. However, they might not deliver the same level of performance as fixed or multi-piston calipers.

Market insights for brake calipers in 2025

Growth and trends

The market for brake calipers is set to experience expansion in 2025 due to advancements in vehicle technology and changing consumer preferences. As per market research forecasts, the current value of the brake caliper market stands at around US $9.97 billion in 2024 and is projected to reach US $13.5 billion by 2029 with a compound growth rate (CAGR) exceeding 3.80%. This growth is primarily fueled by the increasing favor towards disc brakes over drum brakes owing to their enhanced safety and performance advantages. The increased desire for disc brakes has led to a demand for top-notch calipers that perform well. Moreover, stringent worldwide safety regulations and an enhanced emphasis on vehicle safety features are speeding up the acceptance of better brake systems. Brake calipers are crucial in fulfilling set standards and meeting consumer needs effectively.

Technological advancements

The brake caliper market is being influenced by progress in technology, which is introducing innovative materials and designs that enhance the performance and integration aspects of braking systems. Aluminum alloys and composites are increasingly being used as materials in these advancements to help decrease vehicle weight without compromising braking effectiveness. Contemporary caliper designs are developed to tackle issues like heat dissipation and prevent brake fade under prolonged use scenarios, making them particularly suitable for performance-oriented and demanding applications. Moreover, combining brake calipers with electronic stability control (ESC) and advanced driver assistance systems (ADAS) boosts safety and dependability. Production processes like high-pressure die casting and precision machining also enhance production uniformity and effectiveness, allowing for cost-effective solutions without sacrificing quality. These improvements establish safety, efficacy, and performance standards in braking systems.

Key factors to consider when choosing brake calipers

Compatibility and performance

Ensuring that brake calipers are compatible with a vehicle’s specifications is fundamental. Factors such as the vehicle’s make, model, weight, and intended use influence the choice of calipers. For example, high-performance cars may need calipers that can handle stress and heat compared to passenger vehicles that might prioritize affordability and dependability. Considering driving scenarios, like city commuting or off-road trips, will affect how much strain is put on the brakes during driving.

Budget and brand reliability

Budget limitations are something to consider when purchasing calipers; however, balancing cost and their lasting advantages in performance improvement over time is crucial. Investing in top-notch calipers from known brands can result in lower maintenance expenses and increased safety measures as time passes. Trusted manufacturers often deliver products that have been tested extensively to ensure their strength and dependability. Analyzing the overall ownership cost, including potential repair and replacement costs, can help you better understand the worth provided by various caliper choices.

Material and coating

The choice of materials in making brake calipers impacts how they work and how long they last. For example, using materials such as aluminum alloys and composites can make them strong but lighter simultaneously, which saves fuel. Furthermore, applying protective coatings is important to make them last longer in tough conditions. Choosing coatings that resist rust and wear can help the calipers stay in shape longer. This is especially useful in areas with harsh weather conditions where road salt is commonly used.

Piston count and design

The number and arrangement of pistons within a caliper play a crucial role in enhancing braking performance. Calipers with multi-pistons ensure even pressure distribution on the brake pads, leading to better braking capabilities and less brake wear over time. Additionally, the size and layout of the pistons impact heat dispersion and how quickly the brakes respond to pressure changes. Knowledge about these factors can help you choose the calipers that suit your performance needs, whether for regular driving or high-performance use.

Top brake caliper models and their features

Leading models in the market

Top-notch brake calipers are known for their modern designs and durable materials. Numerous versions utilize aluminum alloys to lower vehicle weight while maintaining strength. Multi-piston setups are commonly employed to improve pressure distribution, stopping capability, and less brake fade. Moreover, certain variations incorporate staggered piston configurations to reduce pad wear and prolong the life of the braking system. Anti-corrosive coatings are a top feature for vehicles exposed to tough conditions, ensuring consistent performance in the long run. These attributes combine to form calipers that balance strength and safety while being efficient.

Innovative features to look for

Modern brake calipers come with many upgrades that boost how well they work and how long they last. They have enhanced heat dissipation systems to keep cool by using cooling channels and clever airflow designs to perform consistently even when things get tough. Thanks to smart technology, some calipers can now keep an eye on their wear and tear and give a heads-up when it’s time for some maintenance. Protective coatings are a must-have nowadays, keeping calipers safe from rust and other damage caused by the elements. All these improvements step up the game regarding braking power and reliability in demanding environments or high-performance situations.

Comparative analysis

When looking at brake calipers side by side for comparison purposes, it’s crucial to consider factors like the price point, longevity, and how well they fit specific uses. Even though sophisticated calipers might come with a high upfront price tag, they usually offer lasting advantages like reduced upkeep needs and improved safety features. The resilience of a caliper is affected by the materials used and whether protective coatings are in place to help it endure heat and harsh environmental conditions. The suitability of a caliper is determined by factors such as its design, whether it’s floating or fixed, and the number of pistons it has to cater to the braking requirements. Thoroughly evaluating these factors guarantees that the selected caliper offers value and performance capability.

Conclusion

Choosing the best brake calipers is crucial to guarantee safety and performance in various vehicle uses. Consider aspects such as compatibility with the vehicle’s requirements, quality of materials used in production, innovative functionalities integrated into the design, and cost efficiency. Features like high-performance structures, effective heat dispersion mechanisms, and protective coatings all play a role in maintaining long-term effectiveness. Balancing these factors with constraints and durability considerations ensures getting the value for your investment. By considering these factors in their decision-making processes, those in charge can get brakes that satisfy both the requirements and practical objectives, resulting in reliable braking capabilities across various settings and circumstances.