Table of Contents

● Introduction

● Market overview

● Different types of vacuum boosters and their features

● Key considerations when selecting vacuum boosters

● Conclusion

Introduction

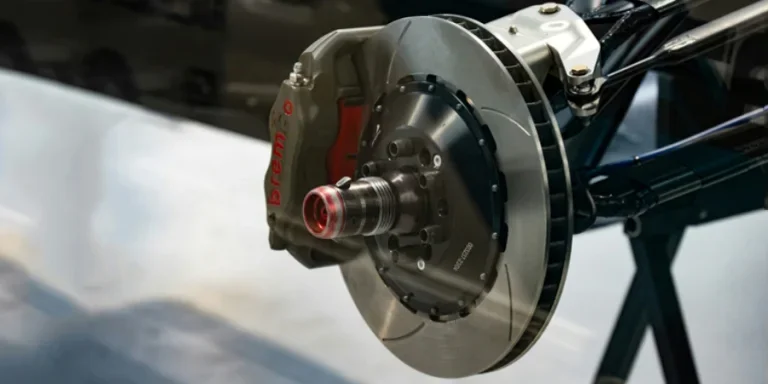

The vacuum booster assembly is vital in modern braking systems, enhancing braking power to ensure quick and safe stops with minimal driver effort. As more vehicles adopt advanced safety features, the demand for reliable vacuum boosters has surged across commercial and passenger cars. This market is rapidly growing due to technological advancements, particularly in electric and hybrid models. Manufacturers are innovating to meet the increasing need for efficient, lightweight solutions that comply with safety regulations. As the automotive landscape evolves, vacuum boosters remain critical for improving overall vehicle performance.

Market overview

The global vacuum booster market is poised for significant growth, with an estimated value of $333.5 million in 2024, projected to reach $680.9 million by 2034, according to Future Market Insights. This growth is primarily driven by increasing demand for advanced braking systems, particularly in electric and hybrid vehicles. The market is expected to expand at a 7.4% compound annual growth rate (CAGR) over the next decade as automakers prioritise safety and efficiency in vehicle braking technologies. Innovations in vacuum booster design, including integrating electronic components, also contribute to this steady rise.

Regarding market segmentation, camshaft-driven vacuum boosters are forecast to hold a 58.8% market share by 2034, owing to their widespread use in conventional vehicles. However, electric brake boosters are quickly gaining traction, driven by the growing production of electric and hybrid cars that require specialised brake boosters to support advanced driver-assistance systems (ADAS). Regionally, the Asia-Pacific market, led by China’s expanding electric vehicle industry, is expected to grow fastest. At the same time, North America and Europe continue to focus on regulatory compliance and technological advancements in braking systems.

Different types of vacuum boosters and their features

Vacuum boosters are critical in enhancing braking performance across various vehicle types and industrial applications. Depending on the vehicle’s design and the specific demands of the application, different types of vacuum boosters offer unique benefits. Below, we explore the key types of vacuum boosters, their features, and where they are most commonly used.

Vacuum brake boosters

Vacuum brake boosters are the most common type found in traditional petrol-powered vehicles. They use the vacuum generated by the engine’s intake manifold to amplify the force applied to the brake pedal. This allows for effective braking without the need for significant driver effort. Their simple design makes them highly cost-effective for internal combustion engine vehicles. However, they have limited application in electric and hybrid cars due to the lack of engine-generated vacuum. According to Custom Market Insights, vacuum boosters remain prevalent in conventional vehicles, but their use is declining as the industry shifts toward electric mobility.

Hydraulic brake boosters

Hydraulic brake boosters use hydraulic pressure from the power steering pump to assist with braking, making them ideal for larger vehicles such as trucks and SUVs. These boosters are designed to deliver greater braking power than vacuum systems, which is critical for heavy-duty applications. While hydraulic systems provide reliable performance in vehicles with high braking demands, they are more complex and expensive. Their components require more maintenance than vacuum boosters, but they offer a significant performance advantage for vehicles that need increased braking force. According to Future Market Insights, hydraulic boosters are expected to continue playing a key role in commercial and heavy vehicles.

Electric brake boosters

Electric brake boosters are essential in modern electric and hybrid vehicles, replacing traditional vacuum boosters. These systems use electric motors or pumps to generate the required vacuum pressure independent of the engine. Electric boosters are highly efficient and vital in supporting advanced driver-assistance systems (ADAS) and regenerative braking. They are becoming more widespread as the electric vehicle market expands, driven by the need for energy-efficient braking solutions. Though costlier to manufacture, electric brake boosters offer superior integration with the latest vehicle technologies. According to IMARC Group, the demand for electric brake boosters is growing rapidly, aligning with the rise in electric and hybrid vehicle production.

Booster pumps in multi-stage systems

Booster pumps are used in more specialised applications, such as vacuum packaging, chemical processes, and industrial systems requiring high vacuum performance. When combined with primary vacuum pumps, these boosters significantly increase pumping speed and depth, improving the system’s overall efficiency. Industries that require precise control over vacuum levels, such as space simulation and packaging, benefit from the performance enhancement offered by multi-stage vacuum systems. According to Nash, these booster pumps can improve performance by a factor of ten, making them ideal for demanding environments where high vacuum performance is essential. The design of these boosters minimises material buildup, ensuring long-term durability and reliability in industrial processes.

Key considerations when selecting vacuum boosters

When selecting a vacuum booster, it is essential to consider various factors that impact performance, cost, and compatibility with specific applications. Each industry and vehicle type has unique requirements, and choosing the right system can optimise efficiency while minimising long-term costs. Here are the key considerations to guide your decision-making process.

Impact of process on pump and vice-versa

When choosing a vacuum booster, assessing how the booster interacts with the application and how the process impacts the pump is crucial. For example, pharmaceuticals and food packaging industries require contamination-free environments, making oil-free vacuum pumps the preferred choice. Any contamination from oil-sealed pumps could affect product quality and safety in these scenarios. Additionally, certain processes that generate dust, debris, or harmful gases may require specialised pumps with appropriate filtration systems or sealed designs to prevent wear and tear. According to Leybold, selecting the right pump must consider these specific application needs to ensure optimal performance and minimal maintenance.

Vacuum level requirements

Different applications demand varying vacuum levels; the chosen vacuum booster must meet those requirements. For instance, electric vehicles benefit from brake boosters designed to function independently of the engine and support advanced systems like regenerative braking. On the other hand, hydraulic brake boosters are better suited for heavy-duty vehicles, such as trucks, that need higher brake force to handle larger loads. Each application, whether in the automotive sector or industrial use, must consider whether the booster will maintain a consistent vacuum level or operate in a pump-down process. According to Atlas Copco, understanding the pressure levels required for each process is critical to selecting the right vacuum technology.

Cost of Ownership

Analysing both upfront and long-term costs is essential when selecting a vacuum booster. Rotary vane pumps, for example, may have lower initial costs but require frequent maintenance due to vane replacements. In contrast, screw dry pumps, while more expensive, offer lower maintenance requirements and longer service life, making them a more economical choice over time. Energy efficiency is another key factor, as some vacuum boosters consume more energy than others, contributing to higher operational costs. According to Leybold, evaluating the total cost of ownership, including maintenance, energy use, and potential downtime, can significantly impact the overall efficiency and longevity of the booster system.

Compatibility with future technologies

As the automotive industry shifts toward electric and autonomous vehicles, selecting a vacuum booster that can integrate with advanced driver-assistance systems (ADAS) and other modern technologies is essential. Electric brake boosters, in particular, are designed to work seamlessly with features like regenerative braking, enhancing both vehicle performance and energy efficiency. According to IMARC Group, the growing demand for electric vehicles is driving the need for advanced braking systems that meet current requirements and future-proof vehicle designs. Ensuring that the vacuum booster system is compatible with emerging technologies will allow manufacturers to stay competitive in an evolving market.

Conclusion

Selecting the right vacuum booster assembly is vital for maintaining efficient vehicle performance and ensuring safety across various automotive applications. With the industry rapidly evolving towards electric and autonomous vehicles, the need for advanced braking systems like electric brake boosters is growing. However, traditional vacuum and hydraulic boosters remain critical for conventional and heavy-duty vehicles, providing powerful, reliable braking performance. When choosing a booster, factors such as the specific vacuum level requirements, impact on the application, total cost of ownership, and compatibility with emerging technologies like ADAS and regenerative braking must be carefully evaluated. Businesses prioritising these considerations will be better equipped to adapt to the shifting automotive landscape while minimising operational costs and maximising efficiency. As the automotive and industrial sectors continue to innovate, investing in the right vacuum booster technology will ensure that vehicles effectively meet safety standards and future market demands.