Anyone who has popped their car’s hood and looked around might have noticed a small electronic component plugged into the intake manifold. That unassuming little sensor is the MAP sensor (manifold absolute pressure sensor), and it has a surprisingly big job: helping the engine control module (ECM) figure out how much air and fuel to deliver to the cylinders.

This article will examine how these sensors work, why they matter, how to spot problems with them, and what to consider when picking the right ones to sell as replacements.

Table of Contents

What does a MAP sensor do?

A quick look at how it works inside

Where MAP sensors work

When the MAP sensor misbehaves: Common failures

Symptoms of a faulty MAP sensor

Diagnosing the Issue

The different kinds of MAP sensors

1. Absolute pressure MAP sensor

2. Gauge pressure MAP sensor

3. Differential pressure MAP sensor

4. Frequency output MAP sensor

5. Analog voltage output MAP sensor

What to consider when choosing a MAP sensor

1. Engine setup

2. Pressure range needed

3. Accuracy & response

4. Signal type

Rounding up

What does a MAP sensor do?

Car engines need a precise mix of air and fuel to run well, and that’s where MAP sensors come in. MAP sensors measure the pressure inside the intake manifold—the duct that channels air (and sometimes air-fuel mix, depending on the system) into the engine. That manifold pressure helps the ECM know how “hard” the motor is working. Here’s a closer at how this happens:

- Low manifold pressure (high vacuum): This pressure typically occurs when the engine is idle or at light throttle. In this state, the ECM adjusts to deliver less fuel.

- High manifold pressure (closer to atmospheric or above in boosted engines): This reading shows a heavier load or a wide-open throttle. Here, the ECM increases the fuel and adjusts ignition timing to handle the increased demand.

The MAP sensor’s reading is, in many ways, a direct indication of what an engine is experiencing at any given moment.

A quick look at how it works inside

Inside a typical MAP sensor, you’ll find a small silicone diaphragm. This thin membrane flexes as the manifold pressure changes. Attached to it is a strain gauge (or similar component) that translates this flexing into an electrical signal. Depending on the sensor design, that signal gets amplified and sent to the ECM as a voltage or frequency output.

In a running engine, the manifold pressure never stays still. Every press of the accelerator, every climb up a steep hill, and every downshift changes manifold pressure. The faster the MAP sensor can register those changes, the more accurately the ECM can respond.

Where MAP sensors work

- Fuel injection systems: These sensors help the ECM strike the ideal air-fuel ratio, especially under varying loads.

- Turbo/supercharger control: MAP sensors can help monitor pressure entering the cylinders in boosted engines.

- EGR (Exhaust Gas Recirculation) control: The ECM might compare pressures to regulate EGR flow, helping reduce emissions.

- Transmission shift points: Some automatics use manifold pressure data for smoother gear shifts.

- Altitude compensation: If owners drive from sea level up to a mile high, the MAP sensor helps the ECM adjust fueling to the thinner air.

- Air/fuel ratio monitoring: MAP data and oxygen sensors can help track or correct the air-fuel ratio.

When the MAP sensor misbehaves: Common failures

If a car is idling roughly or gulping down more fuel than usual, the culprit could be a failing MAP sensor. Common problems include:

- Damaged wiring or connectors: Heat and vibration under the hood can cause breaks or corrosion.

- Clogged vacuum lines: The sensor never “sees” the true manifold pressure if the vacuum reference line is blocked.

- Sensor contamination: Oil blow-by, soot, or general grime may build up on the sensor’s port.

Symptoms of a faulty MAP sensor

- Rough idle or engine stalling

- A hesitation on acceleration

- Higher fuel usage (rich air-fuel mixture)

- Engine code or check engine light

Diagnosing the Issue

Mechanics and DIY enthusiasts often pull out a scan tool to check for codes. MAP-related error codes typically point straight at the sensor itself or something in its wiring. A quick look under the hood may reveal a loose connector or a cracked vacuum hose. Sometimes, a simple vacuum gauge can compare manifold pressure against the sensor.

The different kinds of MAP sensors

1. Absolute pressure MAP sensor

This MAP sensor reads manifold pressure relative to a perfect vacuum. Because it can measure above atmospheric pressure, it’s great for boosted applications.

2. Gauge pressure MAP sensor

This sensor measures relative to ambient atmospheric pressure. So, it’s often cheaper and simpler for naturally aspirated engines.

3. Differential pressure MAP sensor

Differential pressure MAP sensors look at the difference between two points, like the manifold and throttle bodies. Sometimes, vehicle manufacturers use this type in EGR or emissions control setups.

4. Frequency output MAP sensor

Instead of a voltage, this type sends out a changing frequency. It’s useful for certain digital-based engine management systems that want a high-resolution signal.

5. Analog voltage output MAP sensor

This type is the most classic version, sending out a voltage that rises or falls with manifold pressure.

What to consider when choosing a MAP sensor

1. Engine setup

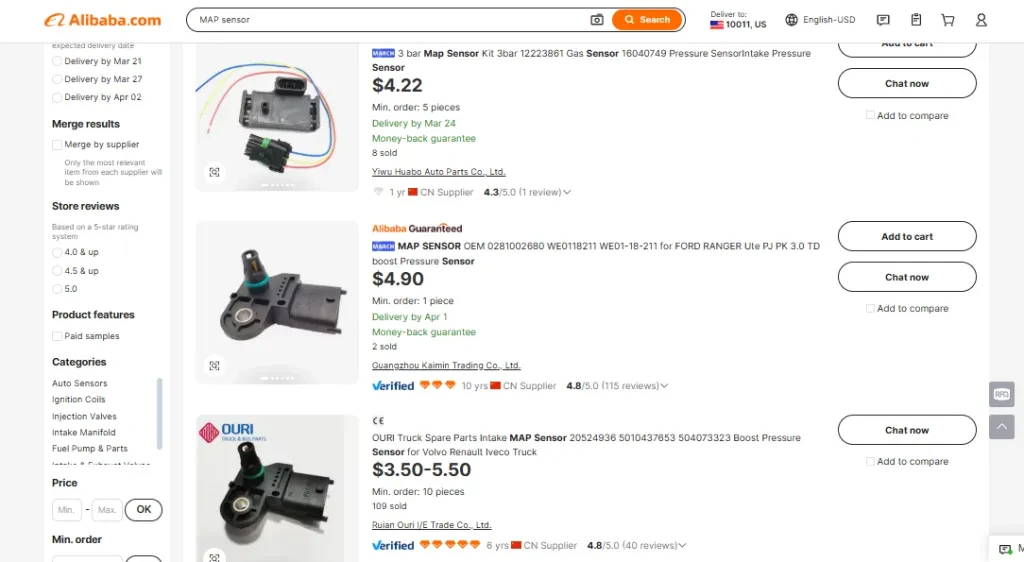

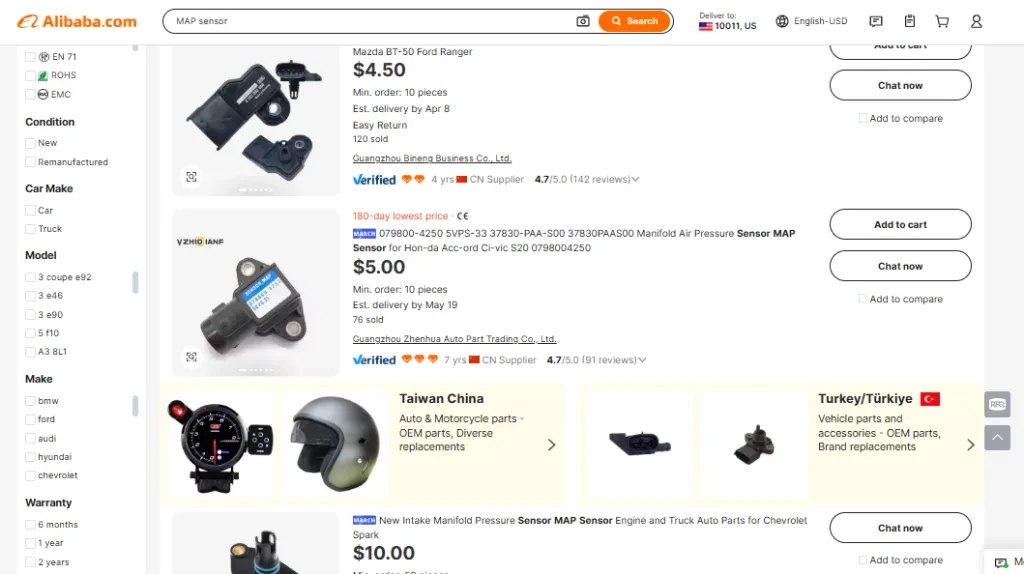

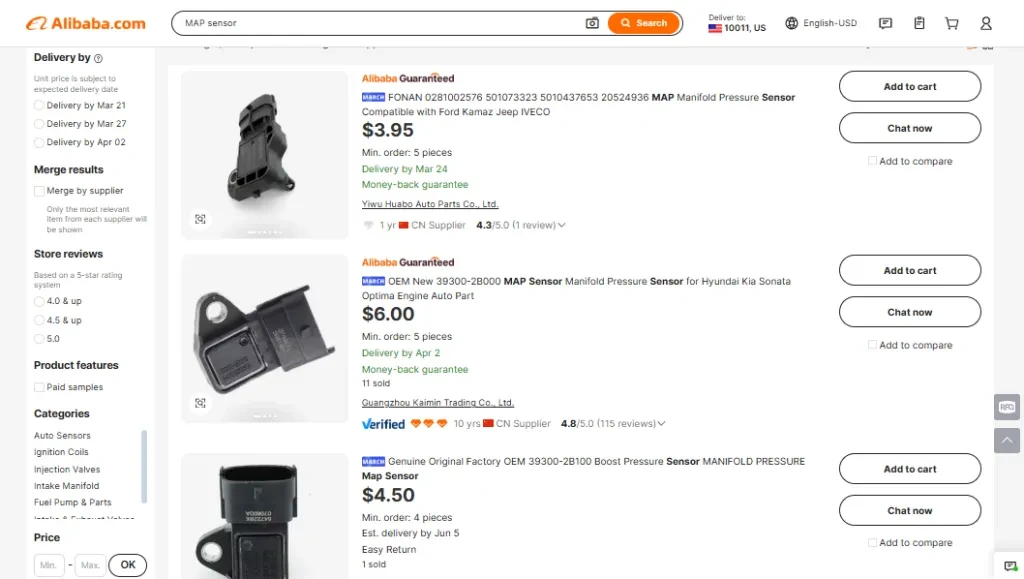

Image source: Alibaba.com

Is the target engine turbo or supercharged? Then, look for a sensor that can read higher pressures (2 bar, 3 bar, etc.). If it is naturally aspirated, then a standard gauge or differential sensor is often enough,

2. Pressure range needed

Double-check the maximum boost or vacuum level. A sensor beyond the consumer’s engine range might offer a resolution they don’t need. For example, a turbo setup that runs 15 PSI (2 bar absolute) will have a safety room with a 3-bar sensor. However, a 5-bar sensor will be overkill unless owners consider extreme tuning. Here’s a pressure ratings guide:

| MAP sensor type | Max absolute pressure | Boost pressure cap (approx.) |

| 1 Bar | 14.7 PSI (atmospheric) | 0 PSI (NA engines only) |

| 2 Bar | 29.4 PSI | 14.7 PSI boost |

| 3 Bar | 44.1 PSI | 29.4 PSI boost |

| 4 Bar | 58.8 PSI | 43.5 PSI boost |

| 5 Bar | 73.5 PSI | 58.8 PSI boost |

3. Accuracy & response

If you’re targeting race cars or performance builds, they demand high-speed responses to sudden throttle inputs, ensuring precise fuel and timing adjustments. If the MAP sensor can’t deliver this high accuracy, it will cause a lagged throttle response, misfire, or incorrect air-fuel ratios. Instead, retailers should stock high-performance sensors.

However, anyone using a mild turbo or naturally aspirated setup won’t need all that power. They will do fine with a standard-quality MAP sensor, which is usually accurate enough to handle normal response times.

4. Signal type

Another factor to consider is whether the ECM can handle the signal from the MAP sensor. If the signal is wrong, drivers will suffer compatibility issues, requiring modifications that can quickly become complicated.

Analog voltage output (most common)

This sensor sends a variable voltage signal (usually 0-5V) to the ECM. They’re the most common OEM and aftermarket sensors for naturally aspirated, turbocharged, and supercharged engines, with the voltages corresponding to direct pressure changes:

- 0V to 0.5V – vacuum (idle or deceleration)

- 2.5V – atmospheric pressure (14.7 PSI at sea level)

- 5V – max pressure reading (varies depending on sensor rating)

Note: Analog voltage MAP sensors can easily integrate with factory ECMs, as most use 0-5V inputs.

Frequency-based output (less common)

These sensors don’t send a voltage signal. Instead, they send a changing frequency signal (Hz) based on manifold pressure. MAP sensors are popular in GM, Ford, and some standalone ECM systems, though not all ECMs support this signal without additional hardware.

Note: Although frequency-based sensors offer faster response times, they are harder to wire and calibrate, especially if users switch from voltage-based MAP sensors.

Rounding up

Although MAP sensors are small, they significantly influence an engine’s performance and efficiency. A faulty one can trigger many issues, from rough idling to poor fuel economy. Fortunately, diagnosing and replacing a failing MAP sensor is usually straightforward, even for at-home mechanics. When consumers are ready to replace or upgrade, retailers must ensure they have a high-quality MAP sensor to meet their needs.