Power relays are essential components in electrical systems, providing control and protection for various applications. This article aims to provide a comprehensive overview of power relays, covering the current market size and future forecast, the common types and features, the latest technological advancements, and selection recommendations to ensure you are stocking the best options for 2025.

Table of Contents

The current global market outlook for power relays

The key parameters of power relay you should know

The common types of power relays and how they differ

The latest relay market trends

How can you select the right power relay for your needs?

Summing up

The current global market outlook for power relays

The global relay market size reached around USD 8.80 billion in 2023. The market is projected to grow at a compound annual growth rate (CAGR) of 6.0% between 2024 and 2032, reaching almost USD 14.87 billion by 2032.

In the future, with the strong growth of smart homes, industrial automation, photovoltaic fields, the rapid development of global meter intelligence, automobile intelligence, new energy vehicles, and the popularity of 5G communication, the relay market will usher in a new round of development.

Relay manufacturers are mainly concentrated in China, Japan, Europe, and the United States. Panasonic and Hongfa are the top two companies in terms of global market share, accounting for about 60% of the market share.

With the continuous development of electrification in the field of new energy vehicles and defense, the demand for power relays will continue to grow. The balanced force relay has been gradually expanded into a high-power relay series to meet the defense field’s high power and current requirements.

Solid state relays are developing in the direction of miniaturization, lightweight, and integration. With the upgrading of defense equipment technology and the development trend of power supply and distribution, the demand for 270V solid power controller products is obvious. The product market will achieve a breakthrough.

The key parameters of power relays you should know

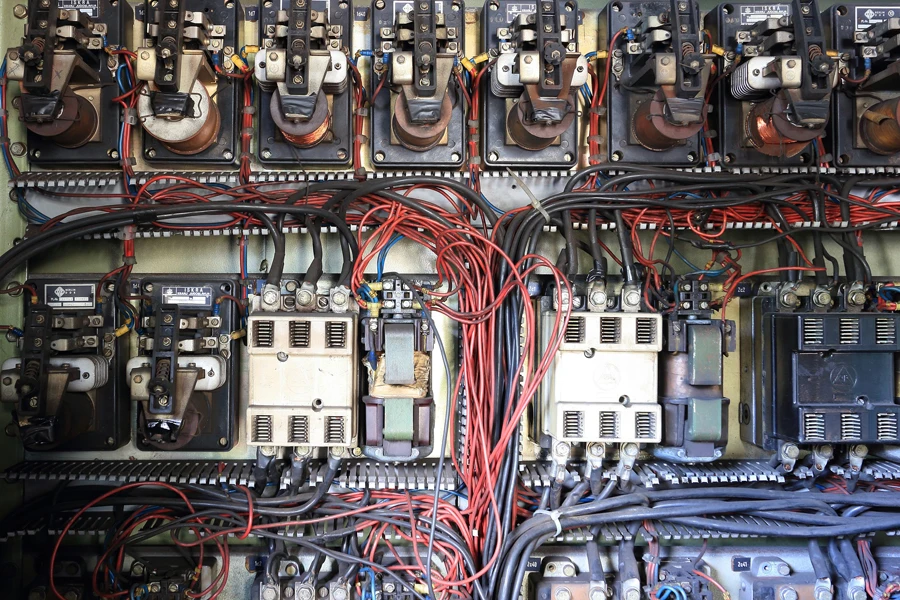

The main function of the relay is to act as a switch to control the operation of other switches in the circuit. They use low-power input signals to control high-power circuits. The low-power signal that activates the relay triggers the electromagnet to energize, thus making the armature move. We will delve deeper into the fundamentals.

1. Electrical parameters

- Rated operating voltage: the input voltage range allowed to be applied when the relay is working normally. One of the important indicators of relay design and performance. The common rated operating voltage is 5V, 12V, 24V, and so on.

- Rated working current: refers to the maximum current value at which the relay can work stably for a long time. It reflects the load capacity of the relay.

- Contact load: including the rated voltage and rated current of the contact, these two parameters jointly determine the maximum power the relay contact can withstand. Common contact load specifications such as 250V/10A indicate that the relay’s contacts can withstand 10A current at 250V.

- Contact resistance: refers to the resistance value of the relay contact when it is closed.

2. Mechanical parameters

- Contact form: Normally Open, NO. When the relay does not operate, the contact is in the disconnected state; When the relay is operated, the contact is closed.

- Contact form: Normally Closed, NC. In contrast to normal open, the contact is closed when it is not operated, and it is disconnected when it is operated.

- Contact form: Change Over, CO. It has a common contact and two switching contacts, and the connection between the public contact and one of the switching contacts can be switched through relay action.

Normally, closed contacts may be more suitable for on-off control of the power supply; switching contacts may be more appropriate in the case of signal switching.

- Operation time: the interval between the relay input signal and the contact action.

- Release time: the time from the input signal’s disappearance to the contact’s recovery.

3. Environmental parameters

- Operating temperature range: indicates the ambient temperature range in which the relay can work normally. The common operating temperature range, such as -40°C to +85°C, indicates that the relay can work normally in this temperature range.

- Humidity range: suitable working and storage humidity conditions, such as 5%-95% RH (relative humidity).

4. Life span

- Mechanical life: refers to the number of times the relay contact can operate reliably, regardless of the current carrying capacity of the contact.

- Electrical life: The number of times the contact can be opened and closed normally under specified load conditions. Electrical life is usually less than mechanical life because current carrying causes contact wear and aging.

5. Encapsulation form

- Plug-in type: installed by inserting pins into the jack of the circuit board, which is relatively convenient to install and replace but occupies a large space.

- Patch type: directly welded to the surface of the circuit board, saving space and suitable for high-density circuit design, but the installation and maintenance are relatively complex.

Normally, power relay products should meet safety standards and have certifications such as IEC and CE.

| AN EXAMPLE OF RELAY RELATED PARAMETERS | |

| Model Number | RXM |

| Mounting Type | Insert and pull out method |

| Description | Mini Power Intermediate Relay |

| Application | Industrial control |

| Current – Input | 3-15A |

| Voltage – Load | 12-220V |

| Current – Output | 3-12A/AC220V DC12V DC24V AC24V AC230V AC110V |

| Load Current | 3-12A/AC220V DC12V DC24V AC24V AC230V AC110V |

| Relay Type | Mini Power Intermediate Relay |

| Coil Current | 3-12A |

| Coil Voltage | AC220V DC12V DC24V AC24V AC230V AC110V |

| Series | RXM |

| Features | Electromagnetic relay |

| Model Number | RXM4LB2BD RXM4LB2P7 RXM2LB2P7RXM4AB2BD RXM2AB2BD |

| Name | Miniature Electromagnetic Intermediate Relay |

The common types of power relays and how they differ

After understanding the basic parameters of power relays, we can classify them in more detail as follows:

Electromagnetic relay

- Normal relay: the most common type of relay, suitable for various load types.

- Magneto relay: a relay specially designed for motor control with a high load current capacity.

- Protection relay: used for the protection and monitoring of power systems, such as overcurrent relay, overvoltage relay, and undervoltage relay.

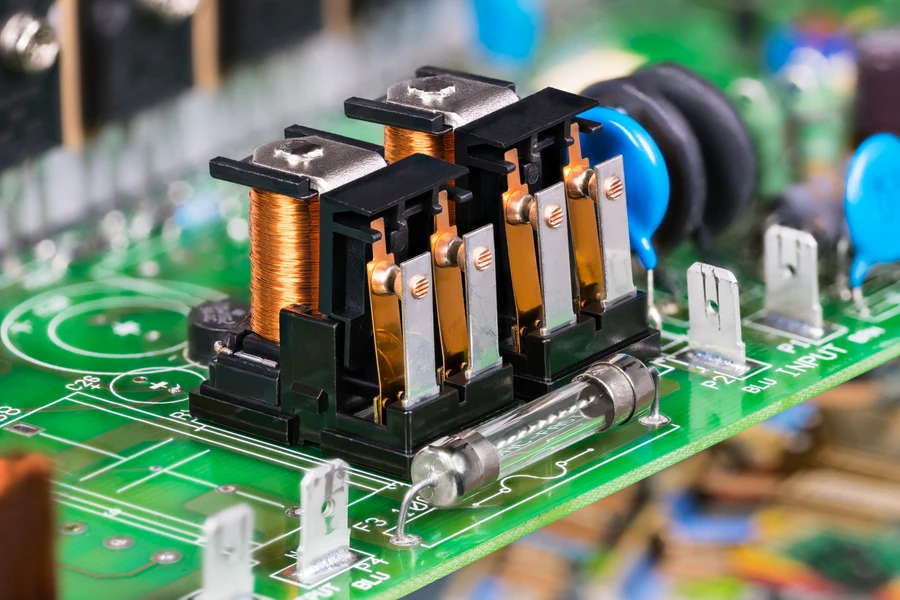

- Solid state relay: uses semiconductor switching elements. People apply them to control electrical loads without using moving parts.

- MOSFET relay: uses MOSFETs as switching elements for low to medium power loads and high-speed switching applications.

- Photoelectric coupling relays: isolation and actuation of circuits using photoelectric couplers for electrical isolation and noise-sensitive applications.

Magnetic holding relay

- Two-coil magnetic holding relays: Two electromagnetic coils are needed to hold the state of the relay, which is switched by changing the direction of the current.

- Single-coil magnetic holding relay: A single magnetic coil is used to maintain the state of the relay by switching magnetic polarity.

Thermal relay

- Bimetal thermal relay: Through the thermal expansion of bimetal sheet to achieve overload protection, suitable for motor and equipment thermal protection.

- PTC thermal relays: Use the characteristics of positive temperature coefficient thermistor (PTC) components for overload protection and temperature control.

Electric relay

- Overload relay: Used to protect the motor from failures such as overload and short circuit.

- Excitation relay: Used to control the excitation circuit of the motor.

Time relay

- Timing relays: Control and operate according to a preset time delay.

- Cyclic timing relay: periodic timing control and operation.

It can be seen that the types of power relays are varied, suitable for various fields, and provide customers with a variety of choices. It has a huge market size in the world.

The latest relay market trends

Technical breakthroughs in power relays are mainly concentrated in the following aspects:

1. Miniaturization and integration

Through integrated design and miniaturization of components, the volume and weight of power relays are significantly reduced, thus improving the flexibility of assembly and space utilization efficiency.

2. Energy efficiency

The new power relay technology uses lower power consumption circuit design and more efficient switching elements such as IGBT and MOSFET to improve power relays’ energy efficiency and energy saving level.

3. High reliability and long life

The application of new materials and manufacturing processes, such as high-temperature resistant materials, vibration resistance, and shock resistance design, helps improve the reliability and service life of power relays.

4. Fast switching speed

High-speed switching and fast response of power relays can be achieved through advanced drive circuits, optimized electromagnetic design, and fast-responding switching elements such as Silicon carbide devices.

5. Intelligence and communication capabilities

With the development of the Internet of Things and intelligent control technology, power relays can communicate and integrate with other devices to achieve functions such as remote control, monitoring, and fault diagnosis.

Technological breakthroughs have made the application of power relays in various fields more extensive and reliable, providing a better solution for power control and energy management needs.

How can you select the right power relay for your needs?

Power relay expertise and selection skills are the foundation for ensuring the safety and reliability of electrical equipment. After reading through the previous sections, we understood the key parameters and common types of power relays. Here are some aspects you need to consider when buying power relays in bulk.

1. Define your needs

Determine the application scenario: whether it is for industrial control systems, home appliances, automotive electronics, etc.

Load characteristics and parameters: Specify the type of load (AC or DC), voltage, current, and power to be controlled in order to select the relay with the appropriate contact load capacity.

2. Consider performance factors

Contact materials and life: High-quality contact materials have better electrical conductivity and wear resistance, as well as longer electrical and mechanical life.

Action time and release time: According to the requirements of response speed, select the relay with the appropriate action and release time.

Anti-interference ability: A relay with strong anti-interference ability should be selected in a complex electromagnetic environment.

3. Focus on brand and quality

Well-known brands: Give priority to products from well-known brands, which are more guaranteed in terms of quality control, technical support, and after-sales service.

Quality certification: Check whether the product has passed the relevant quality certification, such as ISO 9001.

4. Test sample rigorously

Before large-scale purchasing, obtain samples for testing to verify that their performance meets your requirements. Voltage, current, and temperature conditions should be of particular concern when testing a power relay.

Summing up

Power relays play a vital role in many electrical and electronic systems, enabling effective control of electrical loads. They protect your equipment from damage and reduce maintenance costs and production losses. By understanding the basics, common types, latest research, and market dynamics of power relays, you can select the best options for your business, ensuring your buyers are offered optimal performance and reliability.