Airbags and seatbelts are often the first things that come to mind when talking about vehicle safety. Yet, there’s another hero quietly working behind the scenes: the anti-lock braking system (ABS). The ABS monitors wheel speed and prevents wheels from locking during hard braking, ensuring drivers don’t skid out of control.

The ABS module is at the center of this system – a critical piece of equipment that reads data and adjusts brake pressure to prevent drivers from losing control on the road. Auto retailers may already sense the importance of these modules. After all, drivers will start looking for reliable replacements when they get the ABS warning light on their dashboard.

The challenge is determining which modules to stock, which suppliers to trust, and how to strike the optimal balance between quality and price. This guide explores why ABS modules matter, how they function, why customers require replacements, and how to stock the right options to drive more sales.

Table of Contents

A quick history of ABS systems

ABS control module basics: What’s under the hood

When to replace an ABS module

Factors to consider before stocking ABS modules

1. Compatibility and vehicle range

2. Quality and testing

3. Inventory management

4. New vs. remanufactured

Wrapping up

A quick history of ABS systems

Before anti-lock brakes became standard in everyday sedans, the concept was first introduced in aircraft to prevent wheels from locking during landings. Automakers then saw the potential to adapt it for cars. By the late 20th century, ABS was on its way to becoming a standard safety feature, evolving and integrating with other systems, such as traction control and electronic stability programs.

ABS control module basics: What’s under the hood

Although experts often refer to an ABS module as a single unit, several parts work together to offer vehicle stability. Here’s what to know about each one:

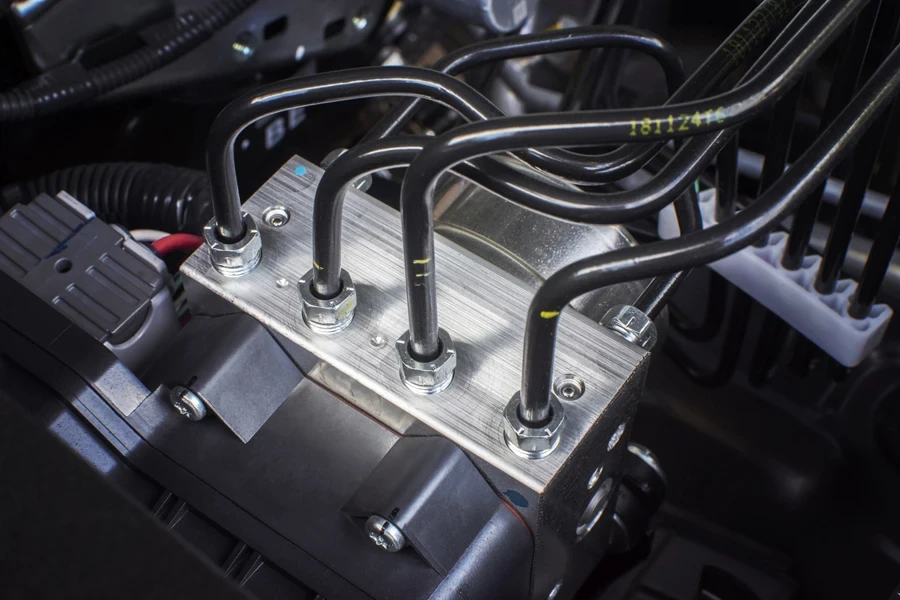

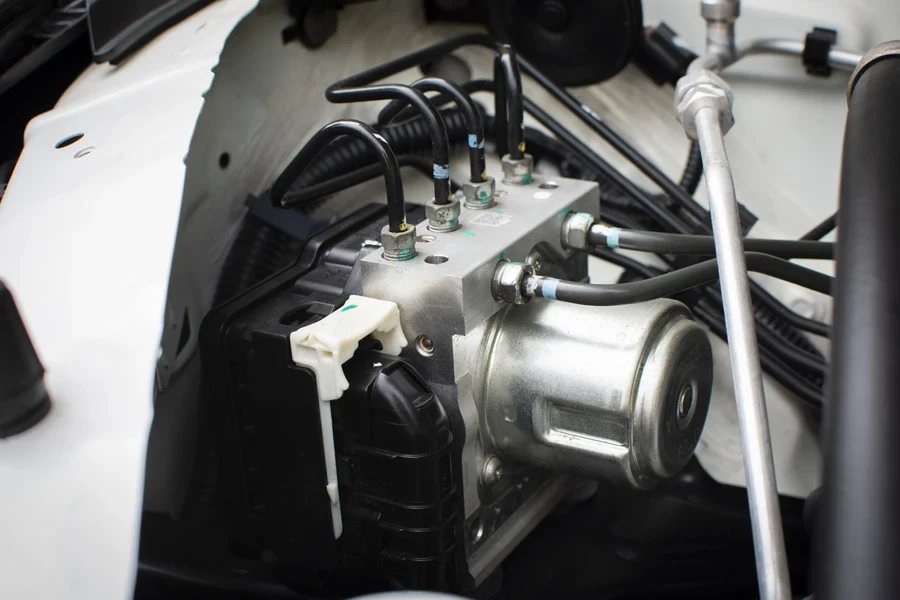

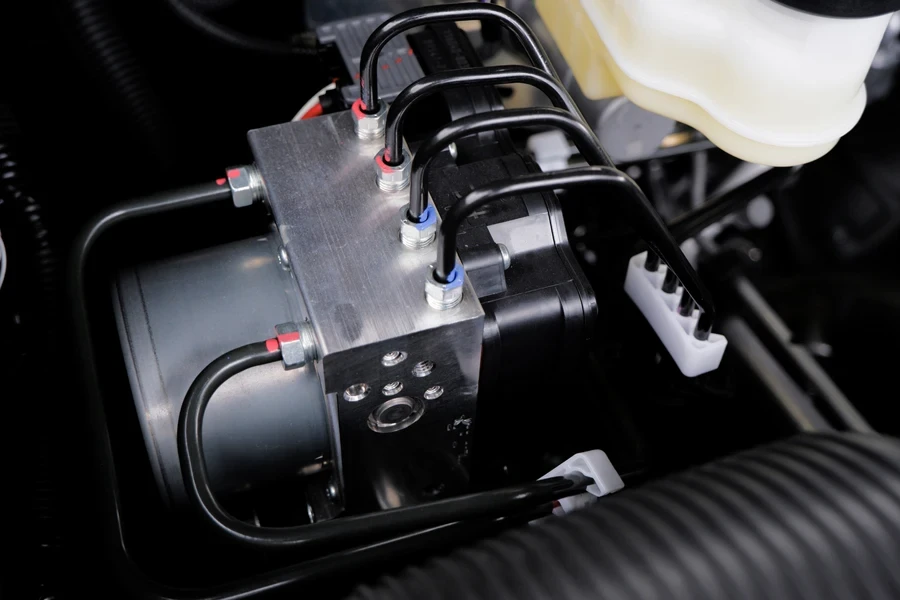

- Electronic control unit (ECU): This component functions like a mini-computer, monitoring wheel speeds. It continuously crunches numbers, reads sensor signals, and sends commands when it detects a skid risk.

- Hydraulic control unit (HCU): This is the “muscle” behind the system. The HCU handles brake fluid flow; when the ECU flags a potential wheel lock-up, it signals the HCU to adjust pressure in microseconds.

- Wheel speed sensors: While not physically inside the module, these sensors feed data to the ECU. Each wheel has its own sensor to check rotational speed. The ABS will step in if one wheel suddenly slows faster than the others.

- Wiring and connectors: The ABS modules utilize wires and connectors to transmit electronic signals. However, corrosion or loose connections can mimic module failure, which can cause frustration if consumers overlook them.

When to replace an ABS module

Consumers are likely to look for ABS module replacement if they encounter:

- Electronic glitches: The ABS light may switch on if the circuit board inside the module has corroded, or one of the solder joints has cracked. Cars are subject to many vibrations, moisture, and temperature fluctuations, all of which can affect the electronics.

- Hydraulic woes: Sometimes, the valves or pump in the HCU fail. If the fluid is contaminated or the pump seizes, the ABS module is rendered useless. Owners may notice something’s off when the ABS light appears or the brakes behave erratically.

- Environmental damage: Road salt, humidity, extreme cold, or heat – these conditions break down metal components and connectors, eventually causing leaks or short circuits

- Accidents: A fender-bender can do more than dent a bumper. The impact near the wheels or braking system can cause the ABS module to become misshapen. Body shops may recommend a replacement if the module housing has structural damage.

- General wear and tear: A module can simply give up after years and miles of faithful service. High-mileage cars, particularly ones with minimal maintenance, are top candidates for ABS-related issues.

Factors to consider before stocking ABS modules

Now for the main event: how do retailers decide which modules belong on their shelves (or in their warehouse)? Here’s what to consider:

1. Compatibility and vehicle range

In a perfect world, one ABS module would work for every car. However, most designs only work with specific models or vehicle platforms. To avoid issues, retailers should always check the following:

- Part numbers: If consumers come in with their old module, retailers can compare the part number with the new one. Minor differences, like whether the vehicle has traction control, can mean consumers require a different module.

- Software/firmware requirements: Some newer ABS modules may need professionals to program or code them to work with the car’s computer. Be sure to advise consumers to find someone with the right tools and expertise to handle such processes.

Retailer tip: Consider labeling each ABS module in your inventory system with all the compatible makes, models, and years. This process helps prevent mistakes, reduces returns, and saves time for retailers and their customers.

Note: Modern vehicles often link the ABS to traction control, ADAS, and stability control. So, retailers must ensure the replacement module for such cars is compatible with all these subsystems.

2. Quality and testing

Not all modules are created equal, and not all suppliers have the same standards. Retailers should look for certifications such as ISO 9001 or TS 16949, which demonstrate they have established quality control processes. If they offer real testing data, like dynamometer tests or bench simulations, that’s even better.

Additionally, consider selecting manufacturers with reliable warranties. A decent warranty shows that the manufacturer or remanufacturer stands behind its product. It also serves as a safety net in case retailers receive a defective batch from the supplier. Standard coverage typically lasts a year, although some policies can be extended for longer periods.

Retailer tip: Request documentation or specifications from manufacturers regarding their testing processes. If they are transparent about it, they are more likely to supply more reliable parts.

3. Inventory management

Retailers shouldn’t fill their shelves with obscure modules for rare cars that never sell. It’s better to start with everyday items and watch sales patterns. If specific modules consistently go out of stock, retailers can adjust their orders accordingly.

Additionally, retailers may need weeks to restock if they rely on a supplier located across the country (or overseas). Knowing the supplier’s delivery timeline is a great way to stay prepared for times of the year when braking issues spike, such as winter or rainy seasons.

Speaking of winter, icy roads expose any weakness in a braking system, so retailers will likely see more ABS-related sales when temperatures drop. Similarly, retailers in regions that experience summer downpours may see a second wave of replacement demands.

4. New vs. remanufactured

New modules typically offer the best performance from the outset. They typically come with the latest updates, improved designs, and solid warranties, all of which provide consumers with extra peace of mind. However, they can be quite expensive. On the other hand, refurbished (or remanufactured) units are a more budget-friendly option.

However, like aftermarket parts, the quality can vary depending on the supplier. A good manufacturing process involves removing a used module, replacing any damaged or worn-out parts, updating electronics if needed, and thoroughly testing it to ensure it works like new. If updated correctly, a remanufactured module can be as reliable as a brand-new one – but at a lower cost.

Retailer tip: If you want to buy remanufactured modules, ensure the manufacturer follows a strict quality control process. Ask what tests they perform and verify if they hold certifications such as ISO/TS 16949 or ISO 9001.

Wrapping up

The ABS module market is highly competitive. However, retailers can stand out by focusing on providing dependable ABS modules and excellent customer support. This means responding promptly to questions, providing expert advice, and maintaining fair and competitive prices. Also, considering the factors discussed above will ensure retailers stock the best quality. When customers know they can trust a retailer’s recommendations, they’ll return for other parts, like brake pads, engine components, or more.