If you are looking for a motor grader, there are many different types and sizes available, so you will want to make sure you choose one that is right for your requirements. How do you go about choosing and what should you look for? This article will offer guidance on the range of machines available, and offer the key factors to consider when choosing a model so you can confidently make the best purchase for your needs.

Table of Contents

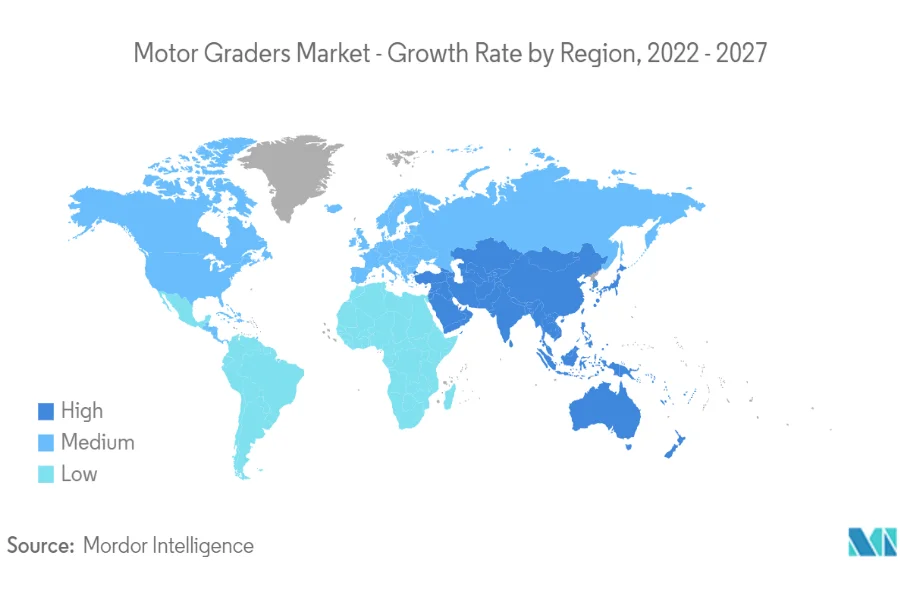

The projected growth of the motor grader market

What to consider when selecting a motor grader

What is the range of motor graders available?

Final thoughts

The projected growth of the motor grader market

With the global construction market now seeing a boost in growth post-pandemic, the market for motor graders is also growing consistently with the construction market overall. In 2021, the grader market was valued at around USD 30 billion, and through 2027 is projected to grow at a compound annual growth rate (CAGR) of over 4.7%. Asia Pacific has led the demand for motor graders due to the boom in construction, with Europe and the US growing a little slower. However, moving forward Latin America is expected to see a higher CAGR, and the US may see a boom if plans progress for investment in the country’s infrastructure.

What to consider when selecting a motor grader

Graders, also called motor graders or road graders, are used to create a smooth road or dirt surface, and in cold climates are also used to clear snow. The first versions were hand or horse-drawn blades, and with the invention of the motorized tractor were then mounted as an attachment. Caterpillar were the first to integrate the grader blade and tractor into a purpose-build design around 1930.

The modern design uses a 3 axle, 6 wheel chassis, with four wheels under the tractor body and two more at the front of an extended frame. The grader blade is mounted under the extended frame and can be moved outwards, rotated, raised or lower, and angled. There is usually a counterweight at the front of the grader.

Types of frame

There are two types of motor grader frame, fixed or rigid frame, and articulated frame. On a fixed frame grader, the main frame or drawbar cannot move. It is fixed and static along the length of the chassis. The front wheels are used to steer. Static frames are much less common now and articulated frame graders have become the norm.

On an articulated frame grader, the main frame is hinged close to the cab body so can move a small amount from side to side to steer the grader. The front wheels also steer as normal. This additional movement gives the grader three different options for steering and mobility:

- Straight steering: Only the two front wheels are used to steer.

- Articulated steering: Both the front wheels and the frame are used for steering, giving the grader a very short turn radius.

- Crab steering: The front wheels remain straight, and only the articulated frame is used for steering.

Size and power

Graders come with differing size and power, with the lower range mini machines at around 100 hp and the larger machines upwards of 200 hp, with the most popular range between 120-180 hp. However, graders are more commonly differentiated by the size of blade, or moldboard, that they can fit and manipulate, with smaller blades up to 10ft (3.2m), and larger blades at 16ft (4.8m) and over. Mid-size blades are the most popular, at between 12ft (3.65m) to 14ft (4.26m).

Types of blade

There are different types of blades that can be fitted, and the cutting edge is important to the job in hand. Blades can be curved or flat, and can have different edges. Scarifier blades can break up hard packed surfaces, whereas dual carbide planer blades are more resistant to impact and erosion so work best on abrasive surfaces. Armored planer blades can handle high impact, for where the blade may hit large obstructions. For cutting edges, there are choices of straight, serrated or toothed edges.

Applications and attachments

Graders are used primarily on construction sites, in mining, and in road building, to create a smooth top surface after other heavier machines have laid down larger material. For example, in road laying, a heavy bulldozer may be used to level out large and small rocks, and the grader then levels a layer of gravel or soil to create a dirt road or to prepare for asphalt. The blade is adjusted for different types of surface and can grade at an angle for slopes.

Graders can be fitted with a front or mid-mount scarifier to break up hard ground, or tear up pavement or asphalt. Modern graders also allow for an attached ripper at the back and a loader bucket at the front. Together with the scarifier, the ripper and front loader bucket, the grader can handle many different kinds of jobs.

When used for snow clearing, the front bucket can be replaced with a V-plow and the sides can be fitted with ‘snow wings’ for wider snow displacement, and the scarifier can break up hard packed ice.

What is the range of motor graders available?

In this section the range of motor graders is split into three power categories, mini graders up to 100 hp, mid-sized graders from 100 to 200 hp, and then large graders of 200 hp and above. Power is not an indication of size of machine, but it does indicate the ability to move heavier ground and to grade down to a depth, although usually not much deeper than about 1½ ft (0.5m). Larger machines can carry larger blades and fit front and rear attachments, but still need power transfer to operate them, so a large machine with less power will struggle with heavier loads.

Mini motor graders (up to 100 hp)

At the 100 hp size, graders are a sensible choice for lighter applications such as working with soft earth and small gravel, such as on small dirt or unfinished roads. They also work well for snow clearing applications. Graders at this power range may have smaller blades, but can also carry mid-sized blades together with front loader and ripper.

Many of the mini graders come with only four wheels rather than the usual six and may not be able to fit a ripper or front loader. So if the requirement is for lighter grading work and easy maneuverability a mini grader with an articulated frame may suit well, and the smaller four wheel machines will fit into tighter project areas. However, mini graders may not fit front and rear attachments, or have sufficient power to operate them well. Conversely, buying a larger powered machine to use only on lighter work will not be cost effective as the additional fuel consumption of a more powerful engine will add to running costs.

Mid-sized graders (100-200 hp)

This size and power range are the most popular for general grading work, being powerful and large enough to suit a variety of road and earth projects. Blade sizes can be fitted up to around 14ft (4.26m) and there is plenty of power to operate a ripper or front bucket.

Mid-sized motor graders are suitable for leveling on large projects and wide roads, such as highways and large construction projects. They have longer blades, have more power than mini graders, and will also have much larger wheels and tire tread.

Large graders (200 hp and above)

There have been some giant motor graders built for custom projects, with one of the biggest ever being the ACCO grader, built for a middle east project in 1980. This beast had twelve tires and two engines, 700 hp for the front and 1,000 hp for the back, and carried a 33ft (10m) blade. However, this is the extreme and most large graders are between 200 and 300 hp with a blade of around 16ft (4.8m).

Graders of this size are used for very large scale land projects, such as mining or quarrying. A typical example of machines advertised for mining and quarrying is the SDLG G9190 200 hp heavy mining grader, with 12.8ft (3.9m) blade.

The larger Shantui SG27-C5 road and mining grader has 270 hp and also carries a 12.8ft (3.9m) blade.

Although most large graders are under 300 hp, there are much larger graders available for mining and large scale projects, such as the XCMG GR5505 mining grader, which wields a massive 550 hp and carries a 24ft (7.3m) blade.

Final thoughts

The buyer’s choice for most suitable motor grader will be project and application dependent. The mid-sized range of graders from 100-200 hp will find use in all sizes of project from small to large, and are plentiful in the market. However, using a large machine for small scale, light road grading may not be very cost effective, and the user may find the blade size too large. For much larger scale projects a mid-sized machine may not have the blade width to be cost effective, nor the horsepower to move sufficient material.

The big machines are always going to be the most effective for large scale construction, road, and mining applications, whereas the mini graders will most likely be best for small road works. For more information on the wide selection of machines available in the market, check out the online showroom at Alibaba.com.