Spark plugs are an indispensable part of a vehicle’s optimal functioning. Being responsible for igniting the air-fuel mixture in the engine, they wield a critical influence over engine performance, directly impacting factors such as cold starts and preventing misfires.

As a result, the significance of keeping spark plugs in good, working condition cannot be overstated, as they directly correlate to maximized vehicle potential and fuel efficiency.

Here, we’ll explore the mechanics behind spark plugs, shed light on indicators that they may be deteriorating, and offer valuable guidance on when they should be replaced.

Table of Contents

An overview of the spark plug market

What are spark plugs, and how do they work?

Are all spark plugs created equal?

What to do with faulty spark plugs, and when should they be replaced

Conclusion

An overview of the spark plug market

The global spark plug market was valued at US $4.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% between 2023 and 2032, reaching US $7.6 billion by 2032.

The key drivers of the spark plug market’s growth include an increased use of natural gas equipment and the rising production of passenger cars worldwide. As the demand for commercial and passenger vehicles continues to rise, the need for spark plugs will also increase.

Geographically, the Asia-Pacific region is the leading regional spark plug market. Boosted by expanding e-commerce, demand continues to heighten across logistics, construction, and mining industries in the region.

What are spark plugs, and how do they work?

Spark plugs have one primary function: igniting the air-fuel mixture within an engine’s cylinders. This ignition creates a controlled explosion that generates the power to propel the car.

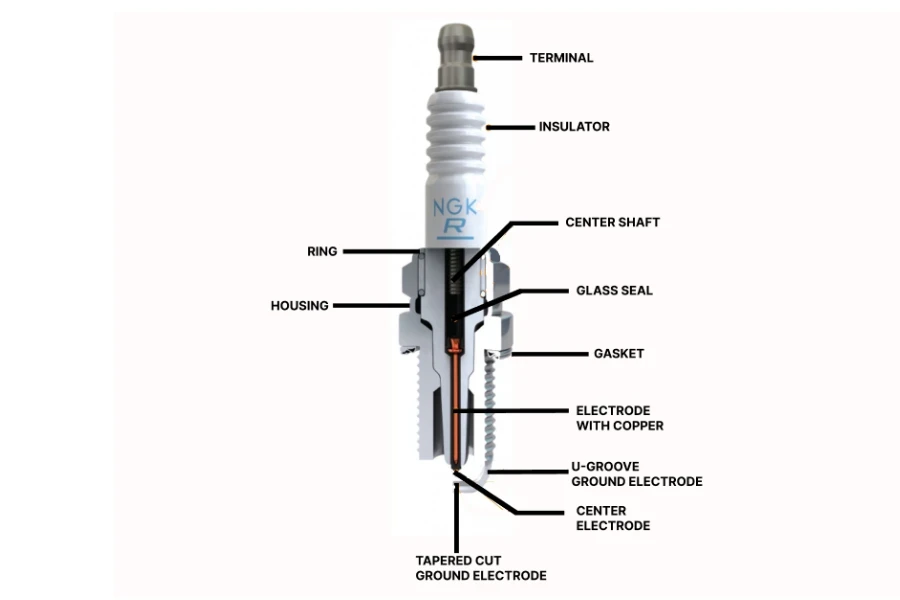

Basically, a spark plug consists of a shell, insulator, and electrodes, which work together to create a spark in an engine’s ignition chamber. Let’s take a closer look at these components:

- Insulator: This component encases the center electrode, terminal, and center shaft, stopping the electricity generated from escaping the spark plug.

- Terminal: This links to the high-tension cord, providing a pathway for the electricity to move from the ignition. Meanwhile, the terminal nut, which are removable, makes the spark plug universally compatible with almost any high-tension cord.

- Ring, packing washer: This creates an airtight seal by fixing the insulator and housing together.

- Center shaft (stem): This component connects the center electrode to the terminal. They’re made from steel, allowing them to handle high-voltage currents.

- Housing: This is the outer shell surrounding the insulator. The housing also supports the insulator and ensures the spark plug fits snugly inside the engine. The ground electrode stays at the bottom of the housing, allowing current to flow from the engine to the center electrode.

- Glass seal: This sits between the insulator and center shaft to sustain airtightness.

- Gasket: This component creates a tight fit around the housing and the combustion chamber.

- Electrode: A sparkplug’s electrodes are made from a special nickel to limit wear damage. Copper is also sealed into the center section to enhance thermal conductivity.

- Center electrode: This lowers the spark’s voltage, reduces the quenching effect, enhances ignition performance, and helps secure suitable sparks.

- U-groove ground electrode: The ground electrode is made from nickel chrome, which helps to improve ignition performance.

- Tapered cut ground electrode: This component reduces the quenching effect, helping improve a spark plug’s performance.

Now we’ll take a look at how spark plugs work:

- Ignition process initiation: The spark plug creates an electric spark across the central and ground electrodes’ gap when the engine’s piston reaches the top of its compression stroke. This spark is generated from the electricity the vehicle’s ignition system supplies.

- Electrical discharge: The high-voltage electrical discharge across the spark plug gap creates a small but intense electrical energy burst. It also ionizes the air-fuel mixture in the combustion chamber, turning it into a conductive path.

- Combustion initiation: The conductive path allows the electrical energy to multiply through the air-fuel mixture, rapidly increasing its temperature. It’s this rise in temperature that ignites the mixture and initiates combustion.

- Power generation: The air-fuel mixture rapidly expands during ignition, creating a high-pressure wave that pushes the piston downward. This downward motion generates enough mechanical energy to drive the vehicle’s wheels.

- Heat dissipation: Spark plugs are designed to quickly dissipate the intense heat generated during combustion. In truth, the ceramic insulator helps to protect the metal shell from the center electrode’s high voltage, preventing electrical leakage and directing the spark’s energy toward the combustion chamber.

Are all spark plugs created equal?

The easy answer is no. Spark plugs vary in design, materials, and specifications. However, there are three easy ways for businesses to tell different spark plugs apart: the numbering system, material, and electrode configuration.

Here’s a detailed explanation for each category and what they mean:

Numbering system

The numbering system is one way to differentiate spark plugs. Each plug comes with a unique code that represents its specifications, allowing businesses to find its suitable equivalent or replacement.

The codes are divided into six parts. Here’s what each one represents:

- The first part of the code represents the spark plug’s shell, thread, and pitch. Although many thread sizes exist, most are specific to the manufacturer’s applications. It also denotes pitch, which measures the gaps between thread peaks. Some standard codes include:

| SHELL | ||

| Code | Thread Size | Pitch |

| A | 18mm x 1” | 1.50mm |

| AB | 18mm x 13/16” | 1.50mm |

| B | 14mm x 13/16” | 1.25mm |

| BC | 14mm x ⅝” (16mm) | 1.25mm |

| BK | 14mm x ⅝” (16mm) | 1.25mm |

- The second part of the code represents the spark plug’s construction. However, this part of the code can consist of more than one letter to indicate multiple spark plug attributes. Here are some of the codes:

| CONSTRUCTION | |

| Code | Meaning |

| L | Compact type |

| M | Compact type (Bantam) ¾” Hex Size |

| P | Projected insulator |

| R | Resistor |

| U | Semi-surface dischargeSupplementary gapSurface gapInductive resistor |

| Z | Inductive resistor |

Note: The “LR” in the BLR5ES spark plug code signifies the plug is a compact and resistor type

- The third part of the segment indicates the spark plug’s heat range. Manufacturers grade them from 2 (hottest) to 12 (coldest). Hence, the “5” in the BLR5ES code is suitable for moderate heat conditions.

- The subsequent letter or letters denote the spark plug’s reach. This reach signifies the measurement between the end of the threaded metal shell and the ground electrode at the plug’s tip.

| REACH | |

| Code | Value (mm) |

| E | 19mm (¾”) |

| EH | 19mm (¾”) Reach Half Thread (12.7mm Threaded) |

| H | 12.7mm (½”) |

| L | 11.2mm (7/16”) |

| S | 9.5mm (⅜”) |

Note: Therefore, the “E” in BLR5Es indicates a 19mm (¾”) reach

- The next part of the code indicates the plug’s firing end construction. The “firing end” or “tip” determines the central electrode’s protrusion, which enhances combustion efficiency. There are four firing tip classifications:

- Recesses: The firing end is positioned within the shell, offering protection for racing engines and robust vibration resistance

- Non-projected: The firing end is mostly leveled with threaded shell’s end. A relatively short tip ensures strong electrode tip vibration resistance and effective thermal conduction.

- Projected: The insulator and center electrode extend beyond the threaded shell, often by 1.5mm. This exposure creates a spark closer to the combustion chamber’s center.

- Extra projected: These plugs offer projections ranging from 2.5mm to 10mm or more. Manufacturers often create custom variants for specific machine applications. Note that incorrect applications can damage engines.

- Lastly, some spark plugs may have a digit at the end of their code. This number indicates the gap size required by the spark plug.

| GAP | |

| Code | Value (mm) |

| 6 | 0.6mm (.024”) |

| 7 | 0.7mm (.028”) |

| 8 | 0.8mm (.032”) |

| 9 | 0.9mm (.035”) |

| 10 | 1.0mm (.040”) |

| 11 | 1.1mm (.044”) |

Note: The codes listed above are only several of many examples

Materials

Depending on the manufacturer’s specifications, a spark plug’s center and ground electrodes are made of different materials. Common materials used include copper, platinum, iridium, and double platinum.

Each material possesses distinct properties that will impact the spark plug’s performance.

1. Copper: Copper, mixed with nickel alloy coatings, offers good electrical conductivity, aiding in efficient spark generation.

Pros

- Ideal for older models, preferably from 1980 or before

- Offers superb performance in turbocharged motors

- Works well in high-compression applications

Cons

- Needs frequent replacement due to shorter lifespans

- Requires additional voltage

Price

- Can cost anywhere between US $2-10 per piece

2. Platinum: Platinum spark plugs are similar to their copper predecessors, except instead of a copper core, the center electrode is made from a platinum disc joined to the tip.

Pros

- More durable than copper plugs (longer lifespan)

- Design reduces carbon buildup

- Offers consistent performance

Cons

- More expensive than copper spark plugs

Price

- Around US $10 per piece

3. Iridium: Iridium spark plugs come with smaller center electrodes and require less voltage to create a spark. Since newer cars with high-performance engines often feature iridium spark plugs, downgrading to platinum or copper variants may lead to reduced performance.

Pros

- Increased durability with exceptional hardness and wear resistance

- Longer lifespans

- Requires less voltage

- Ensures complete combustion

Cons

- More expensive than other spark plug materials

Price

- Anywhere from US $20-100 per piece

4. Double platinum: Double platinum spark plugs feature center and ground electrodes tipped with platinum. They are more common in modern engines, which demand high ignition system efficiency.

Pros

- Ideal for wasted spark ignitions

- Increased durability

- Reliable performance

Cons

- More expensive than copper and single platinum plugs

Price

- Around US $20 per piece.

Electrode configuration

Spark plugs have different electrode configurations that can impact their performance and efficiency. Here are the most common designs:

- 1. Single electrode: In this basic configuration, the spark plug has a single center electrode and a single ground electrode. It is a simple design suitable for standard engines with moderate performance demands.

- 2. Multiple ground electrodes: Some spark plugs feature multiple ground electrodes surrounding the center electrode. The additional ground electrodes improve spark stability and enhance ignition reliability.

- 3. Fine wire electrode: Fine wire spark plugs have a thinner center electrode made from precious metals like platinum or iridium. The reduced diameter of the center electrode enables a more concentrated spark, promoting efficient combustion and better engine performance.

- 4. Surface discharge electrode: This configuration features a flat-surfaced ground electrode, allowing the spark to discharge along the surface rather than jumping the gap

What to do with faulty spark plugs, and when should they be replaced?

Over time, spark plugs become less efficient due to various factors that affect their performance. Here are some common reasons why spark plugs lose effectiveness:

- Wear and erosion: A spark plug’s electrodes experience wear and erosion after repeated ignition of an engine’s air-fuel mixture. The constant electrical discharge generates heat, gradually eroding the electrodes’ surfaces. This process increases the electrode gap, reducing a spark plug’s ability to produce a strong and consistent spark.

- Fouling: Deposits from the combustion process, such as carbon, oil, and other contaminants, can accumulate on the spark plug’s electrodes and insulator. These deposits form a layer that inhibits the spark’s ability to jump across the electrode gap, reducing the spark plug’s effectiveness.

- Heat and thermal stress: Spark plugs operate in an extreme environment and are exposed to intense heat and thermal stress during engine combustion. The repeated heating and cooling cycles can cause the spark plug’s components to expand and contract, potentially leading to cracking or damage, further reducing performance.

- Electrical resistance: The spark plug’s internal components can develop electrical resistance due to corrosion or aging. Higher resistance impedes the flow of the electrical current, resulting in weaker sparks, which can lead to misfires and decreased engine efficiency.

- Insulator breakdown: The insulator surrounding the center electrode can degrade over time due to harsh operating conditions. Cracks or breakdowns of the insulator material can compromise the spark plug’s ability to maintain proper voltage insulation, leading to potential misfires.

- Gap growth: As the spark plug experiences wear and erosion, the electrode gap increases, requiring a higher voltage to jump the greater distance. This increased voltage demand can strain the ignition system, potentially leading to ignition system malfunctions.

Conslusion

Spark plugs are crucial to the health of any vehicle’s engine, and several variables affect how fast they may need replacing. While spark plug problems may seem insignificant initially, using a faulty plug can lead to various more severe complications.

Thankfully, most spark plugs can last for solid periods or mileage, reducing the need for frequent replacement. However, if any of the issues listed in this article occur, it’s advisable to replace them as soon as possible.

For a huge range of spark plugs and other car accessories and parts, visit Alibaba.com.