Before the internet era, small businesses and brands needed to rely heavily on local directories, trade shows, professional networks, and word-of-mouth referrals to find a trustworthy manufacturer who could turn their new product ideas into reality.

Today, finding a manufacturer has become as simple as a few clicks. Businesses can now request quotes, compare bids, view product samples, and even check the manufacturer’s credentials online.

But how can businesses begin their online search for manufacturers? Moreover, given the abundance of product manufacturers worldwide, how should a business determine and select the one most suitable for their manufacturing needs? Read on to find out where and how to find the right manufacturer in no time!

Table of Contents

Supplier vs. manufacturer: Aren’t they the same thing?

What factors to consider when looking for a manufacturer?

How to find a manufacturer online?

Get started and turn your product ideas into a reality

Supplier vs. manufacturer: Aren’t they the same thing?

When looking for a manufacturing partner that can transform an innovative product idea into a physical product, it’s important to remember one key truth. While all manufacturers are suppliers, not all suppliers are manufacturers. Some suppliers are actually intermediaries or middlemen, connecting buyers to the actual manufacturers.

So, before we explore where businesses can find a reliable manufacturer, let’s first clarify the different types of suppliers and how to identify the actual manufacturers among them.

Manufacturers

A manufacturer holds the top position in the supply chain pyramid as the originator of goods. It’s an entity that employs systematic processes and specialized machinery to design, assemble, and test an array of items. These items may consist of individual components or encompass fully-finished products.

Manufacturers are divided into types according to their role in production. Some use their large machinery to manufacture high-quality products from clients’ designs, while others handle everything from design to testing and production themselves. Let’s explore the different types of manufacturers:

Original equipment manufacturer (OEM)

An original equipment manufacturer (OEM) is a type of manufacturing company that produces specific parts or components, as per the client’s design, which are then used in the final products of other companies.

For instance, Bosch is a leading German OEM that manufactures essential components such as car batteries, spark plugs, and brake systems that are used in automobiles made by companies like Ford or Toyota.

Original design manufacturer (ODM)

An original design manufacturer (ODM), also known as a private label manufacturer, is responsible for designing, developing, and producing products for other companies. Unlike OEMs, which focus solely on manufacturing items based on a client’s design, ODMs create both designs and finished products ready for branding by other companies.

For instance, Compal Electronics is a well-known ODM that designs and manufactures laptops, computers, and tablets for companies like Dell, HP, and Lenovo. Foxconn is another established ODM known for producing electronics for leading brands like Apple, Nokia, and Sony.

Contract manufacturer (CM)

A contract manufacturer (CM) is a manufacturing company that produces goods under the label or brand of another firm. The process typically involves a client company supplying a design or formula to the CM, which then produces and packages the finished product.

While it might look similar to OEM services, a CM offers more comprehensive services. Beyond just manufacturing, a CM can also manage material sourcing, quality checks, and assembly and packaging of the final product.

It’s like being given a recipe (a.k.a., the design) but also being responsible for getting the ingredients, ensuring they’re top quality, doing the cooking, and presenting the finished dish beautifully.

Wholesalers and distributors

While some manufacturers choose the Direct-to-Consumer (DTC) strategy to sell their goods directly to the customers, many still lean on intermediaries to sell their products in large quantities. A distributor often serves as the first contact point for manufacturers within the supply chain.

These distributors often have exclusive agreements with a manufacturer partner, permitting them to purchase, stock, and sell their products, typically within a designated region. Moreover, distributors usually bring extra value to this relationship by offering services like marketing help, technical assistance, and post-sales support.

Conversely, the primary role of wholesalers is buying products in vast quantities, at a lower price, either from manufacturers or distributors, and selling these in smaller quantities to retailers. The retailers then sell these products to the end consumers.

Unlike distributors, wholesalers often collaborate with various overseas manufacturers and are not subject to exclusive contractual obligations. They mainly focus on making a broad range of products accessible to retailers.

Trading companies

Trading companies act as ‘product connectors’ in the business world. They buy a wide array of products in large quantities from various sources like manufacturers, distributors, or other wholesalers and then sell these goods to various markets like small businesses and retail customers. It’s easy to confuse them with wholesalers, but there are distinct differences.

Firstly, trading companies deal in a broad product mix, sourcing from various regions and even multiple countries. Wholesalers, on the other hand, usually specialize in specific types of products. They purchase large volumes of these products at discounted rates from international manufacturers or distributors and resell them in smaller quantities within their local region or market.

Secondly, trading companies have a global reach – they flourish in diverse markets, and their operations are usually international. They play a key role in facilitating the exchange of goods across international markets, managing logistics, customs clearance, and documentation. This is the primary reason why most suppliers on B2C and B2B e-commerce websites are predominantly trading companies.

What factors to consider when looking for a manufacturer?

With a vast network of suppliers accessible online, identifying a good manufacturing partner can be challenging. There are several potential risks, such as language barriers causing misunderstandings or misinterpretations regarding product specifications and shipping times.

Furthermore, remote management may complicate overseeing quality procedures. Here are five factors to consider when looking for a manufacturer that can transform a good idea into a great product:

Experience and expertise

When initiating the search, the first aspects businesses should focus on are the experience and expertise of potential manufacturers. Experience refers to the history and track record of a manufacturer. For example, a furniture manufacturer that has been in operation for 30 years and has worked with known brands in producing high-quality furniture pieces exhibits desirable experience.

Besides experience, a manufacturing company should demonstrate expertise in their particular field. Expertise refers to a manufacturer’s specialized skills or knowledge in a specific area of manufacturing. This could range from expertise in particular materials, production techniques, or specific types of products.

For instance, a business seeking to produce environmentally friendly furniture should prioritize manufacturers known for their sustainable production methods, such as zero-waste manufacturing, utilizing recycled materials, or promoting energy efficiency throughout the manufacturing process.

Certifications

Once businesses have evaluated the experience and expertise of potential manufacturers, the next step is to check for necessary certifications that demonstrate compliance with quality, safety, and regulatory standards.

Recognized third-party organizations often provide these certifications. Here are some noteworthy certifications to consider when assessing a manufacturing company:

- ISO 9001: This certification shows that the manufacturer adheres to internationally recognized quality management standards, fulfilling customer and regulatory requirements consistently.

- ISO 14001: This certification demonstrates that the manufacturer has an environmental management system in place and is actively reducing their negative carbon footprint.

- CE Marking: These two letters “CE” on a product signal adherence to European Union standards regarding safety, health, and environmental protection.

- FCC: Given by the Federal Communications Commission, this certification testifies that the manufacturer’s electronic products comply with international regulatory standards.

- FSC: This certification indicates that wood or paper-based products are sourced from responsibly managed forests, upholding important ecological and social benefits.

- RoHS: Manufacturers with RoHS (Restriction of Hazardous Substances) compliance certify that their products limit the use of specific hazardous materials, protecting both the environment and consumers.

- IATF 16949: Pertinent to the automotive sector, this certification verifies the manufacturer’s robust quality management systems, aiming at continuous improvement, reducing waste, and preventing defects.

Alibaba.com has expanded its marketplace with a dedicated European Pavilion, which exclusively features EU/UK-certified items. Buyers can easily access this resource by logging into the Alibaba.com App and selecting the “Certified picks for Europe” link on the homepage.

Quality control procedures

Quality control procedures are essential in determining how manufacturers maintain high-quality standards in their produced goods. Businesses need to understand the systems a manufacturer has in place to ensure the products are consistently being made as per required specifications.

Here’s a simple table that businesses can use as a reference when reviewing the quality control aspects of potential manufacturers:

| Quality control aspect | What it involves |

| Traceability of raw materials | This aspect revolves around the manufacturer’s ability to track the journey of raw materials through the production phases. By knowing the origin and stages of their raw materials, a manufacturer can ensure the quality and compliance of all the elements that go into a given product—like a chef knowing each ingredient’s provenance in a recipe. |

| Number of QA/QC inspectors | QA/QC inspectors, also known as the “quality control team,” are the gatekeepers of the production process. They regularly examine each production line, ensuring that each product meets their rigorous standards before it leaves the factory. This is like a meticulous supervisor checking every meal in a restaurant before it reaches the diners to ensure perfection. |

| Product inspection methods | These are systematic checks during the production process to ensure that the final product meets quality standards. For instance, a manufacturer may use visual checks (looking for any physical abnormalities on the product), functional tests (ensuring the product works as designed), and measurement checks (verifying the product’s dimensions align with specifications). |

| Equipment maintenance | This quality aspect refers to how the manufacturer takes care of their production machines and tools. It’s like the servicing and upkeep of the car to ensure it runs smoothly for a long time. Businesses need to know if their potential partners have a regular maintenance schedule, if their equipment is modern or outdated, how often they calibrate their machines, and how they handle equipment breakdowns. |

Production and R&D capabilities

Just as it’s vital to consider a manufacturer’s quality control, it’s equally crucial to assess how quickly they can produce goods while still maintaining the agreed-upon quality standards. Here are the key factors to consider when evaluating a manufacturer’s production capabilities:

- Number of machinery and production lines: Similar to the horsepower of a car, the number of machinery and production lines shows the basic capacity of the manufacturer. More machinery and production lines often signify a higher output magnitude.

- Efficiency of equipment used: The efficiency of these machines reflects their modernization and maintenance level. It’s like the condition of a car engine; better efficiency can lead to higher productivity, quality, and, often, cost-effectiveness.

- Workforce size and training: The strength and expertise of the workforce are central to the smooth operation of the production lines. It’s similar to having experienced drivers at the wheel who know how to handle the vehicle even under unexpected conditions.

- Lead times: Businesses need to pay attention to the lead time, which indicates the time taken by manufacturers to complete an order from initiation to delivery. This is akin to estimating the time it takes to drive from point A to B.

Aside from production capabilities, businesses should also carefully assess a potential manufacturer’s research and development (R&D) capabilities:

- Patents and intellectual property (IP): A manufacturer with a good number of granted patents or protected IP often signifies their investment in R&D.

- Testing facilities: A manufacturer should have dedicated testing facilities to evaluate product performance under various conditions.

- Adoption of modern technologies: Consider whether the manufacturer is using recent advances in technology, such as the Internet of Things (IoT), artificial intelligence (AI) systems, or robotics.

Pricing and minimum order quantities

After meticulously evaluating potential manufacturers, from their experience to their R&D capabilities, the last deciding factor is their pricing and minimum order quantities. This could be the make-or-break point in choosing a manufacturer.

Pricing refers to the cost that the manufacturer charges for producing the product. To determine fair pricing, businesses need to send a request for quotation (RFQ) to several manufacturers. By doing so, they can compare prices and gain a better understanding of the financial feasibility of manufacturing their product.

Minimum order quantities (MOQ), on the other hand, are the least number of units a manufacturer requires for an order. For instance, When a small business approaches a T-shirt manufacturer, they may state that their MOQ is 100 units. This MOQ means that buyers can’t just order a single T-shirt or even 50 T-shirts. The smallest order the manufacturer will accept and produce is 100 T-shirts.

How to find a manufacturer online?

While online directories prove to be a beneficial starting point in the search for manufacturers, it’s quite challenging to verify the legitimacy of the listed manufacturers. Directories are platforms where anyone can list their business, which can potentially expose buyers to trading companies disguised as manufacturers or, even worse, to fraudulent entities.

However, a leading online B2B marketplace like Alibaba.com can smooth out the search process and eliminate these headaches. What makes Alibaba.com stand out as a great manufacturer directory is the “Verified Supplier” program. This program employs third-party experts to conduct in-person audits of factories to make sure the manufacturers are legit.

Moreover, the innovative feature of 360° Virtual Reality (VR) showrooms allows buyers to explore the factories of potential manufacturers virtually. This provides businesses with a first-hand view of the machinery and processes in action. Sounds promising, doesn’t it? Let’s check out how to find manufacturers on Alibaba.com in 5 straightforward steps:

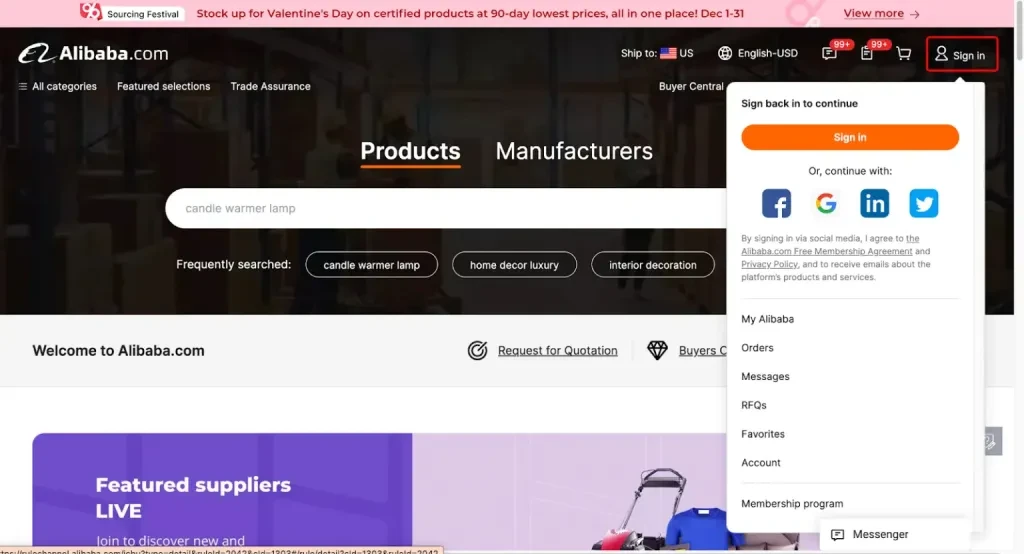

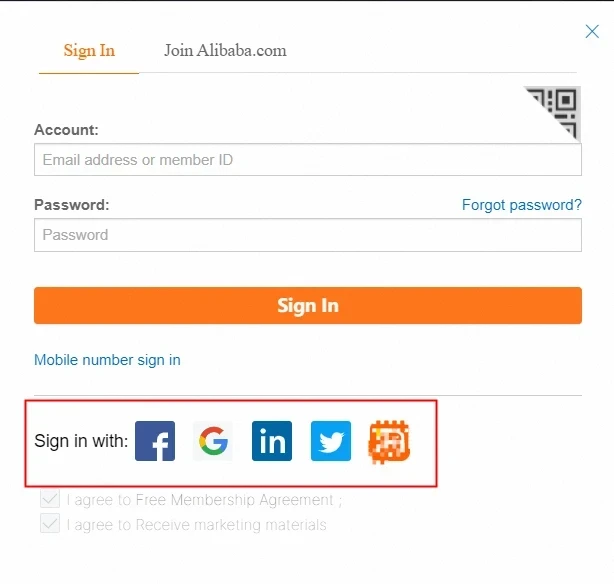

Step 1: Log in to Alibaba.com

After creating a buyer account, the first step is to log in to Alibaba.com. Users can do this either directly from the official website or from the mobile app, as demonstrated in the screenshots below.

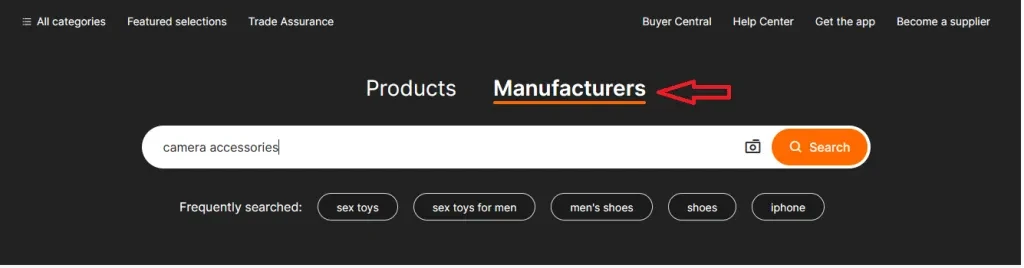

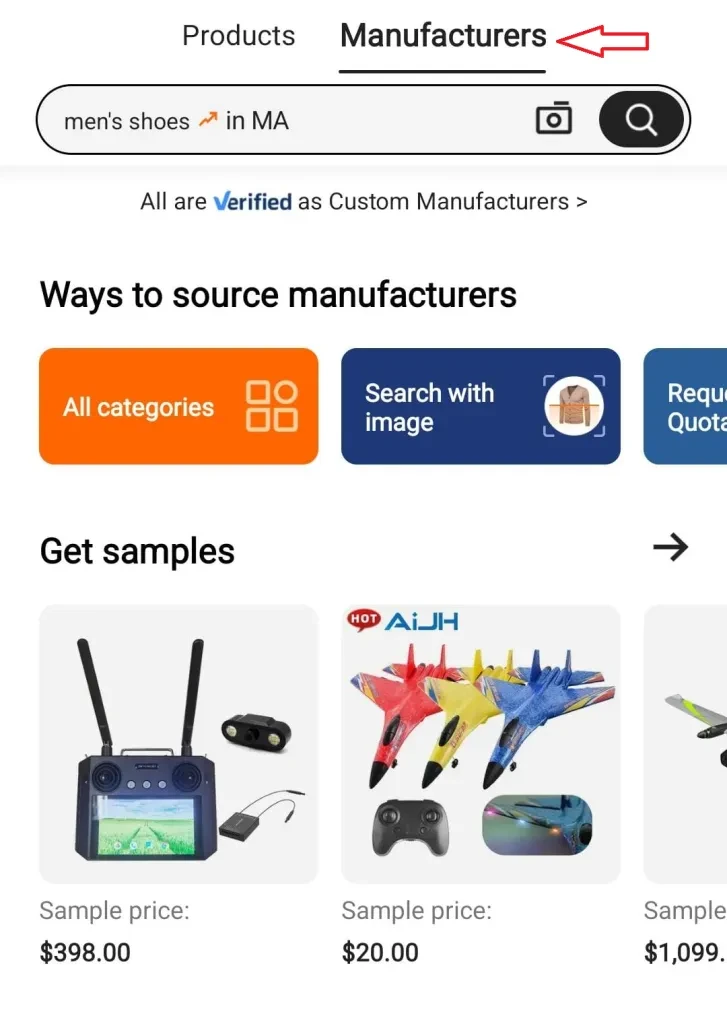

Step 2: Locate the ‘Manufacturers’ tab

On the homepage, click the “Manufacturers” tab and type in a product name or category in the search bar. Thousands of manufacturers will appear instantly. The platform features over 30,000 verified custom manufacturers across 5,900 product categories.

Step 3: Refine the search results with filters

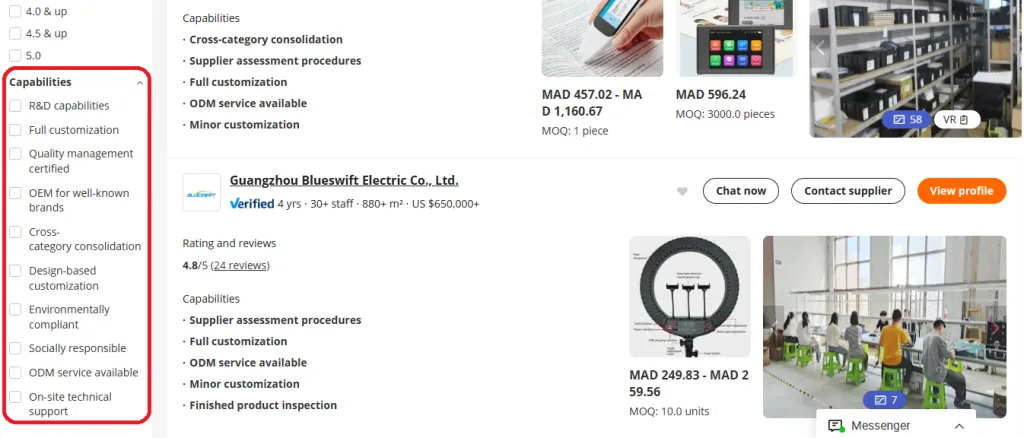

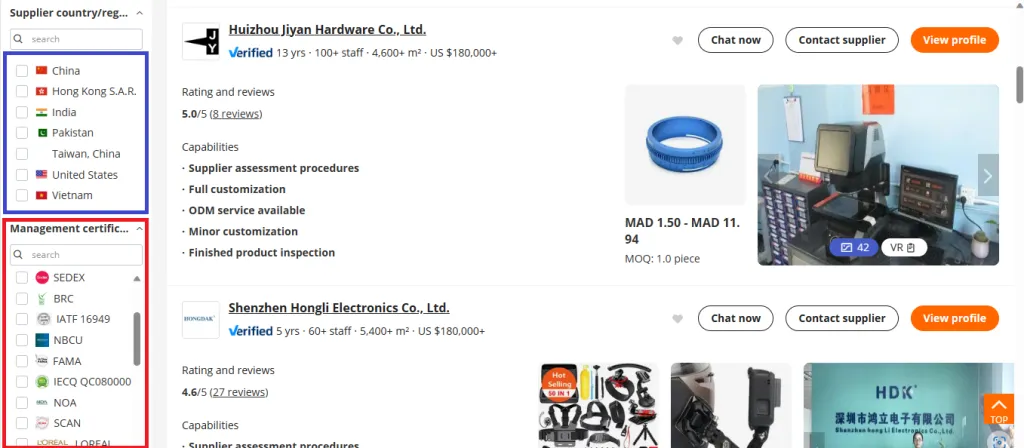

Next, users can refine the search results by using the left-hand filters. These filters let users narrow down manufacturers by their capabilities, location, and certifications. For example, users could find Chinese manufacturers who provide full customization services and have OEM experience with popular brands.

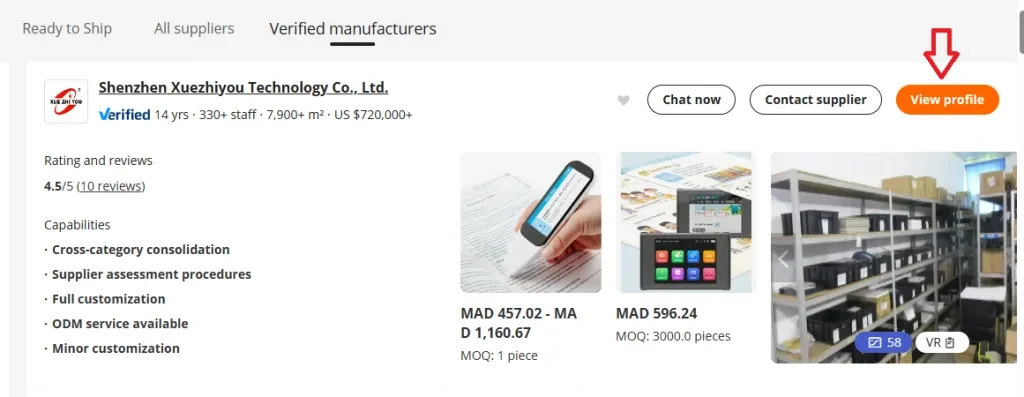

Step 4: Navigate to the manufacturer’s profile page

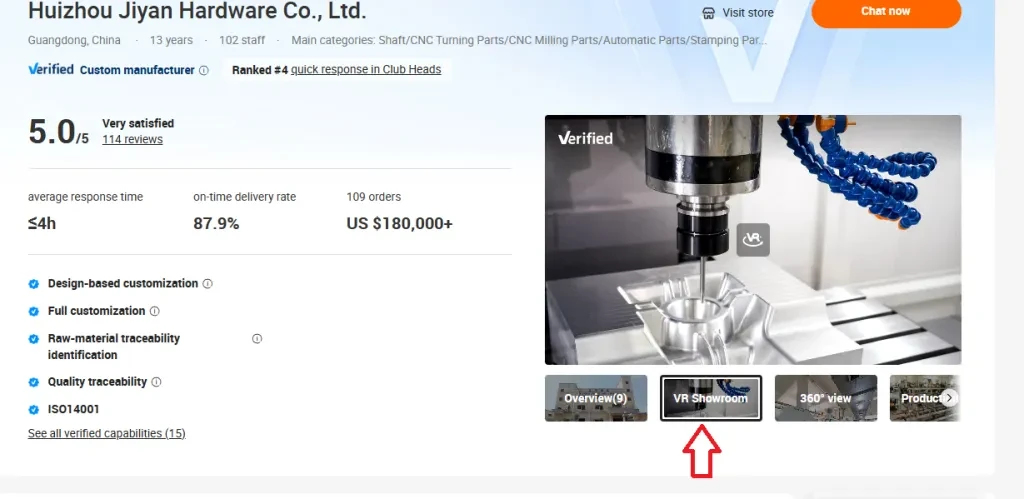

When buyers find a manufacturer that sparks their interest, they can click “View profile” to visit the manufacturer’s detailed information page and explore further.

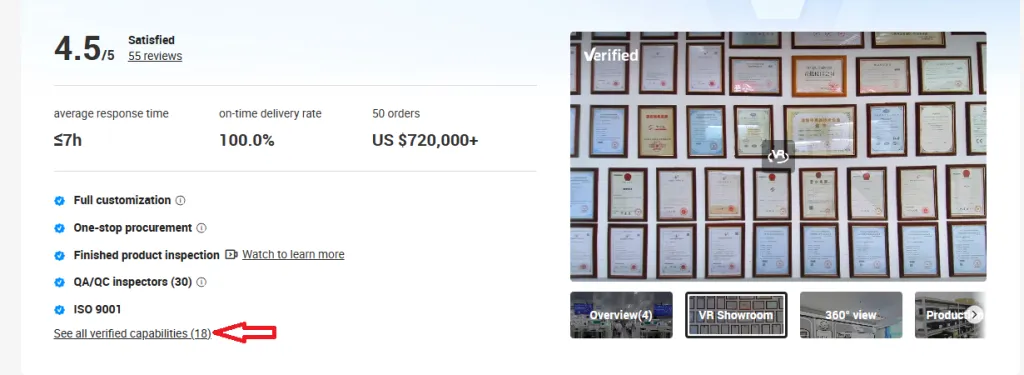

When users are on the manufacturer’s information page, they can look into the following details:

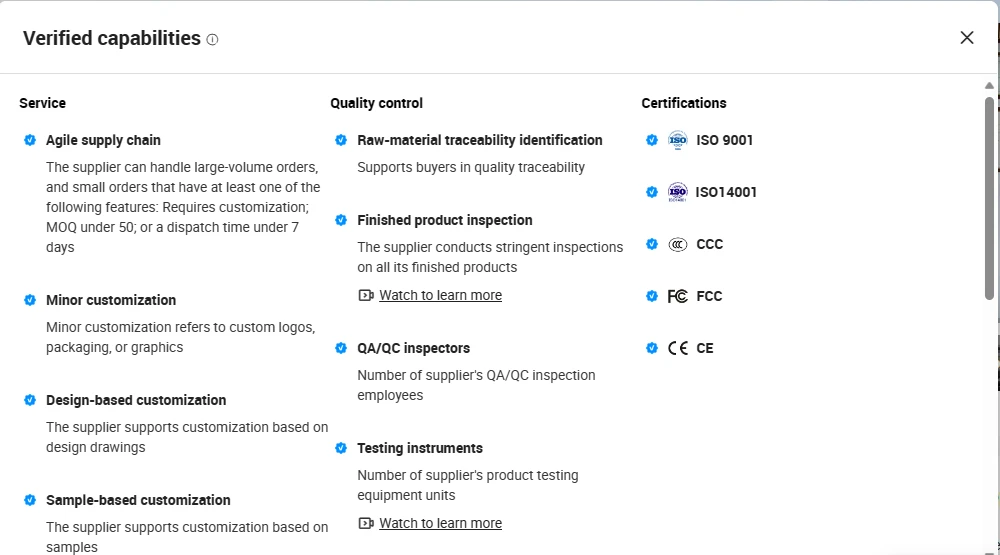

- Capabilities: Click “See all verified capabilities” to review the services, quality control methods, and available product certifications provided by the manufacturer.

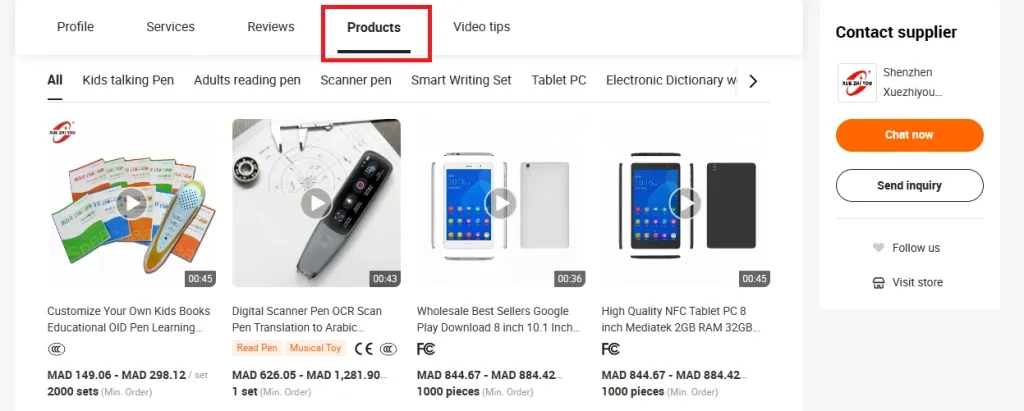

- Available products: To view the manufacturer’s product offerings, buyers can scroll down to the products section or click the ‘Products‘ tab on the upper-side bar. Typically, a manufacturer demonstrating expertise in their field will focus on products within a single category rather than offering a wide variety of categories.

- VR showroom: For a digital walk-through of the factory, users can simply click “VR showroom” on the right-side navigation bar. This gives buyers a chance to view the equipment, watch various production stages, and explore the facility as if they were actually there.

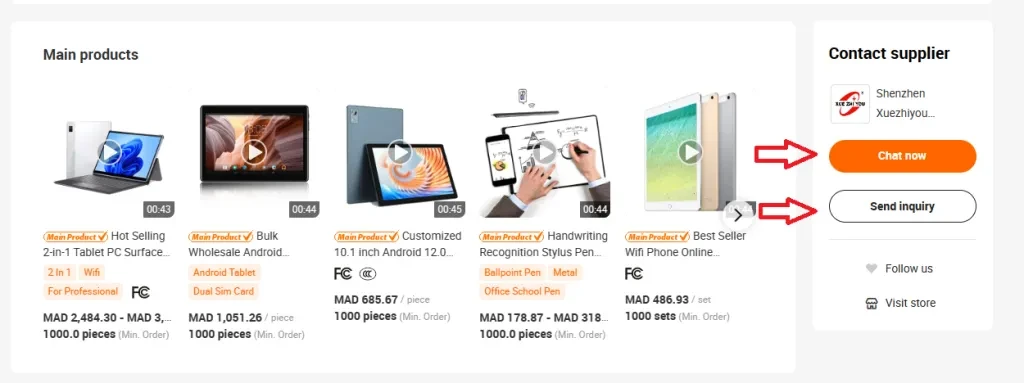

Step 5: Reach out to the selected manufacturer

After choosing a preferred manufacturer, users can click “Chat now” or “Send inquiry” to get in touch. To request ODM or OEM services, buyers should send an RFQ containing product design details, such as dimensions, color, and material, as well as any necessary branding information like logo files.

Get started and turn your product ideas into a reality

To sum it up, businesses are fortunate to live in an era where geographical boundaries blur, and thousands of global manufacturers are just a button click away. The right manufacturer can turn product ideas from an abstract concept into physical, real-life items.

So, why wait? Start by following these 7 easy steps to craft your first product blueprint. Once you’ve done that, visit Alibaba.com to find a manufacturing partner who can bring your product idea to life.