Global supply chains represent a complex, interlinked network orchestrating the movement of goods and services. This intricate system comprises numerous components, including suppliers, manufacturers, distributors, retailers, and ultimately, the customers.

The adoption of supply chain technologies and software tools can provide businesses with an upper hand in managing this complicated network. New technologies can dramatically improve visibility, foster better coordination, automate repetitive tasks, and expedite decision-making processes.

Keep reading as we look at how technology impacts supply chain management by examining five supply chain technologies that will help companies manage their operations with ease and efficiency!

Table of Contents

How does technology impact supply chain management?

Five supply chain technologies that will reshape the future

Prepare for supply chain technologies: challenges & solutions

How does technology impact supply chain management?

Technology has become a cornerstone of supply chain management, bringing in unprecedented changes that improve efficiency, reduce costs, and enhance customer satisfaction.

From using robots and the Internet of Things (IoT) in warehouses to leveraging artificial intelligence (AI) in demand forecasting, companies are extensively adopting and integrating advanced supply chain technologies.

Here’s how technology is transforming traditional supply chain management:

- Enhanced visibility: Companies are now adopting technologies such as RFID and IoT to boost traceability throughout the supply chain. This not only offers up-to-date and accurate information on product status but also enables real-time decision-making based on the current state of the supply chain.

- Improved productivity: Adopting robotics and automation into manufacturing operations can rapidly increase productivity. These technologies are capable of performing repetitive tasks faster and with more precision, providing businesses with an opportunity to optimize their resources.

- Accurate demand forecasting: With the help of AI and machine learning, companies can predict product demand more accurately. This innovation allows better inventory management and prevents stock-outs or excess inventory, ultimately leading to cost savings.

- Effective communication: Supply chain technologies are no longer limited to physical operations. Cloud-based platforms and digital tools have made it possible for seamless communication and collaboration, not only within the organization but also with external partners and suppliers.

Five supply chain technologies that will reshape the future

So we know how technology is becoming the backbone of global supply chains, but which specific technologies are going to be game-changers? Let’s explore 5 supply chain technology trends that could change the way businesses operate forever.

1. Predictive analytics with AI and machine learning

In today’s competitive landscape, the ability to understand and predict customer behavior is vital for companies striving to succeed in the marketplace. As customer expectations continue to evolve rapidly, businesses must recognize the significant shift in purchasing values and motivations.

A recent Accenture survey of 25,000 global consumers found that 33% of respondents reported that their preferences are changing regularly. To stay ahead of the curve, more businesses are turning to artificial intelligence (AI) and machine learning as solutions for analyzing historical customer data and forecasting future demand.

Predictive analytics, fueled by AI and machine learning, allows businesses to analyze big data, such as social media posts or product reviews, to make accurate predictions about how customers will behave in the next month, week, or day.

For example, e-commerce businesses can use machine learning algorithms to assess past purchasing and browsing history to create personalized experiences for their customers. This approach is similar to Netflix’s movie recommendations, only in this case, movies are replaced with products.

2. Real-time tracking and traceability with IoT

Supply chain management has always been complex as it involves various stages from raw materials acquisition to final product delivery. Increasingly, the focus is shifting towards enhancing end-to-end visibility and transparency in this process through real-time tracking and traceability.

This pivotal transformation will be facilitated by the Internet of Things (IoT) technology, offering e-commerce businesses the ability to track product locations and monitor transportation routes of goods instantaneously.

IoT can be conceptualized as a network of physical devices, ranging from vehicles to everyday objects embedded with smart sensors and network connectivity. This networking allows these objects to autonomously collect and exchange data, contributing to an intelligent and dynamic supply chain.

For instance, perishable food items could be stored and shipped in smart containers equipped with GPS tracking and environmental sensors such as RFID tags. These tags can even respond to temperature changes, assisting businesses in maintaining the optimal conditions necessary for their perishable products during transportation.

Moreover, integrating IoT technology with warehouse management offers traceability of inventory from the initial purchase order through delivery. When inventory on a specific shelf falls below a certain threshold, for example, IoT systems can generate automatic replenishment alerts.

3. Digitization of supply chains through cloud computing

As of 2021, a remarkable 40% of industry professionals have already integrated cloud computing into their supply chain operations. This shift towards cloud-based solutions speaks volumes about the significant advantages that cloud computing brings to the table.

One of the most notable benefits is that it allows companies to store data in the cloud rather than on their physical servers. This eliminates the need for businesses to invest heavily in purchasing and maintaining costly infrastructure, while also ensuring that their sensitive data is less vulnerable to cyber threats.

Supply chain managers can now access their company’s data from their mobile devices whenever they need it, providing unprecedented accessibility and control over vital supply chain processes. From tracking shipments to monitoring inventory levels, cloud computing has made these tasks more efficient and manageable than ever before.

For example, businesses can leverage solutions like Alibaba’s Elastic Compute Service (ECS) to create a decentralized system where they can effectively track supplier performance metrics, including on-time deliveries, lead times, and the quality of goods.

Furthermore, cloud-based platforms can process incoming sales orders and automatically trigger crucial warehouse events such as picking, packing, and shipping, significantly enhancing supply chain responsiveness and efficiency.

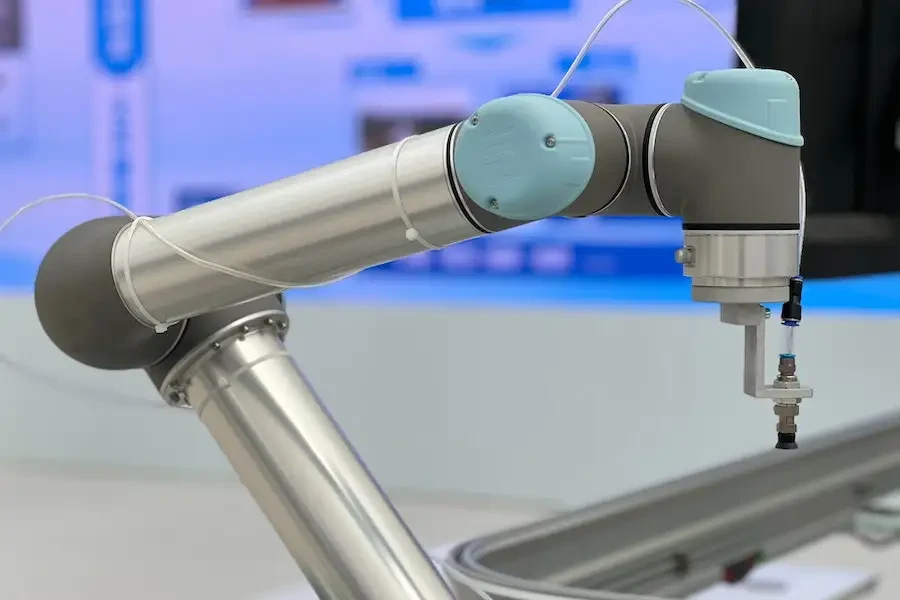

4. Automated warehouses and transportation with robotics

In recent years, automation and robotics have expanded beyond their traditional roles in manufacturing to play a vital part in supply chain operations, particularly in transportation and warehousing.

For example, autonomous mobile robots (AMRs) can be used in warehouses to perform repetitive or manual tasks, such as picking, packing, and sorting or moving pallets and carts through spaces. By implementing AMRs in their operations, businesses can significantly reduce their picking times, in instances cutting them by nearly 50%.

Additionally, the use of autonomous vehicles and drones is revolutionizing the delivery process, allowing for faster and more accurate deliveries without human intervention. This proves particularly beneficial in delivering packages to remote or hard-to-access areas. For instance, drones can be the most efficient form of transporting essential supplies in disrupted situations caused by natural disasters or infrastructure failures.

Notably, automation is not limited to the use of robotics and self-driving vehicles. Companies can also adopt robotic process automation (RPA) to streamline various supply chain operations such as order processing and shipment scheduling.

With RPA, software bots can automatically extract order information from online stores or incoming emails and enter the data into order management systems, resulting in more efficient and error-free data entry.

Furthermore, these bots can generate a delivery plan by selecting the most cost-effective and timely freight option based on parameters such as package weight, destination, and customer delivery window.

5. Adaptive packaging and space optimization with 4D printing

In the era of additive manufacturing, 3D printing has revolutionized the way physical products are created from digital blueprints. This innovative process constructs complex shapes by adding layers of material, as opposed to traditional manufacturing methods which cut, drill, or carve objects from larger blocks. As a result, 3D printing minimizes material waste.

However, recent engineering advancements have introduced a fourth dimension—time—into the equation, leading to the development of 4D printing. Four-dimensional printing technology allows businesses to use smart materials that respond to external stimuli, with some materials possessing the ability to return to a predetermined shape when exposed to triggers such as heat, electricity, or light.

This means that companies can design containers or boxes that adjust their size and shape according to the items being transported, resulting in the most efficient use of space and improved stackability.

Additionally, product packaging could be designed to expand and provide extra cushioning in response to pressure, ultimately protecting items from harsh handling. The potential applications for 4D printing in the supply chain are endless.

Prepare for supply chain technologies: challenges & solutions

Technological innovations are transforming every aspect of supply chain operations. From AI and machine learning to 4D printing, these emerging tools and technologies will reshape the future of supply chain management.

However, as promising and beneficial as these advancements are, it’s not as simple as just adopting a new tool and expecting immediate results. Following are some of the key challenges and potential solutions when adopting new supply chain technologies:

| Challenges | Potential solutions |

| Resistance to change | Involving employees in the decision-making process and providing in-depth training programs |

| High costs | Opting for a phased introduction of the technology, starting with a pilot project and gradually scaling up |

| Security threats | Conducting regular security audits and creating a reliable data backup and recovery plan |

Are you still struggling with which supply chain technologies to start with? Get started with improving visibility with these three cost-effective tools!

Looking for a logistics solution with competitive pricing, full visibility, and readily accessible customer support? Check out the Alibaba.com Logistics Marketplace today.