In today’s business world, time is precious. With the many competitive pressures and ever-evolving business models, businesses must reduce their development cycles, be innovative, and implement new ideas quickly.

The world of manufacturing and prototyping has witnessed a radical transformation thanks to the advent of 3D printing technologies. Also known as additive manufacturing, 3D printers enable the formation of three-dimensional objects layer by layer based on digital models.

Over the years, with better-performing 3D printer machines, more materials, and the ability to deliver 3D-printed parts, this technology has evolved significantly, becoming a driving force in various industries. Therefore, it’s essential for related businesses to understand the fundamental principles of 3D printing and its current state so as to appreciate the current landscape and forecast future trends – read on to learn more.

Table of Contents

Fundamental principles of 3D printing

State of 3D printing technology

Emerging trends in 3D printing

Conclusion

Fundamental principles of 3D printing

3D printers rely on an “additive process,” wherein the printing process materials are placed layer by layer via an electron beam to create a tangible object. This departure from traditional subtractive manufacturing processes has allowed for unprecedented design freedom and intricate geometries that were once impossible.

3D printing has shown itself to be an essential time and cost-saving option in design and manufacturing pursuits, and has fundamentally changed how people manufacture goods. More importantly, it has many strategic benefits and implications, boasting flexibility, design freedom, distributed manufacturing, and the ability to mass-customize products.

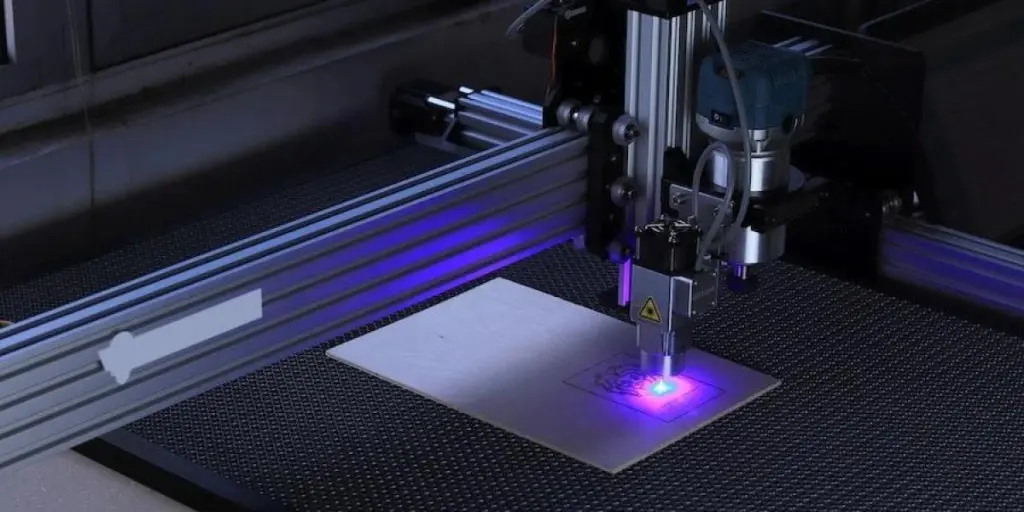

The most common 3D printer technologies include selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA), each with their unique set of applications and advantages.

State of 3D printing technology

According to research by Markets and Markets, the global 3D printing market was valued at US $15.0 billion in 2023 and is estimated to grow at a CAGR of 18.1%, reaching US $34.5 billion by 2028.

The rise in value of 3D printing technology is mainly attributed to ongoing government investment, aggressive research and development, and growing demand for cutting-edge products. Industries related to aerospace, healthcare, automotive, and consumer goods are embracing 3D printing for prototyping, customization, and end-use production.

However, there are some constraints regarding the growth of 3D printing technologies. For instance, the raw materials used in 3D printing cost more than the raw materials used in traditional manufacturing processes. Moreover, there remains a lack of standardized testing to verify the mechanical properties of the 3D printing materials.

These factors notwithstanding, 3D printing technology is poised to redefine the future of manufacturing.

Emerging trends in 3D printing

3D printer technology has now been around for nearly a decade, and various trends continue to shape it. Some of the emerging 3D printing trends include the following;

Sustainability

One of the prominent trends shaping 3D printing today is a heightened focus on sustainability, in part thanks to more and more people becoming sustainability conscious. Thanks to its cleaner industry credentials, additive manufacturing is becoming a more dominant technology in achieving sustainability goals and reducing manufacturing-related carbon footprints.

While traditional manufacturing methods often generate significant waste, 3D printing’s additive nature minimizes material usage. Moreover, the ability to recycle and repurpose certain 3D printing materials aligns with the growing global emphasis on eco-friendly practices.

Cost reduction

As technology advancements become more accessible, the cost of 3D printing steadily decreases. This trend is fostering a broader adoption of the technology in industrial applications.

Initial 3D printer machine costs may be high, but rapid prototyping speeds help to reduce costs thereafter. These advancements will continue to accelerate as more businesses adopt 3D printing.

In addition, the decline in material waste, energy consumption, and labor costs makes 3D printing a cost-effective manufacturing solution. There is also no overproduction in 3D printing as manufacturers only produce what is needed on demand, also helping to reduce transportation costs.

Data security and data integrity

As 3D printing becomes more integrated into production processes, the importance of data security and integrity in this realm is becoming increasingly prominent. 3D printing relies on digital technologies, fueling growing concern for data security and integrity.

Protecting intellectual property and ensuring the authenticity of digital files has become a critical consideration in the 3D printing landscape.

Businesses and companies must ensure their intellectual property is protected, utilizing parameters to encrypt them.

Ensuring the confidentiality, integrity, and availability of 3D printing data has become crucial to leveraging this technology to its fullest potential. Innovations in secure file transfer protocols and encryption technologies are emerging to address these challenges.

Hybrid material innovations

As industries push the boundaries of what they can achieve via additive manufacturing, incorporating hybrid material is a game-changer, offering endless and unprecedented possibilities in functionality, versatility, and durability.

Hybrid material innovation in 3D printers integrates different materials, each chosen for its unique characteristics, to create structures with enhanced properties that often surpass individual materials’ limitations.

Hybrid materials combine metals, ceramics, polymers, and even biological substances, for instance, for use in tissue engineering. These innovations open up new possibilities for applications in the electronics, medical, aerospace, and automotive industries.

Application-driven production

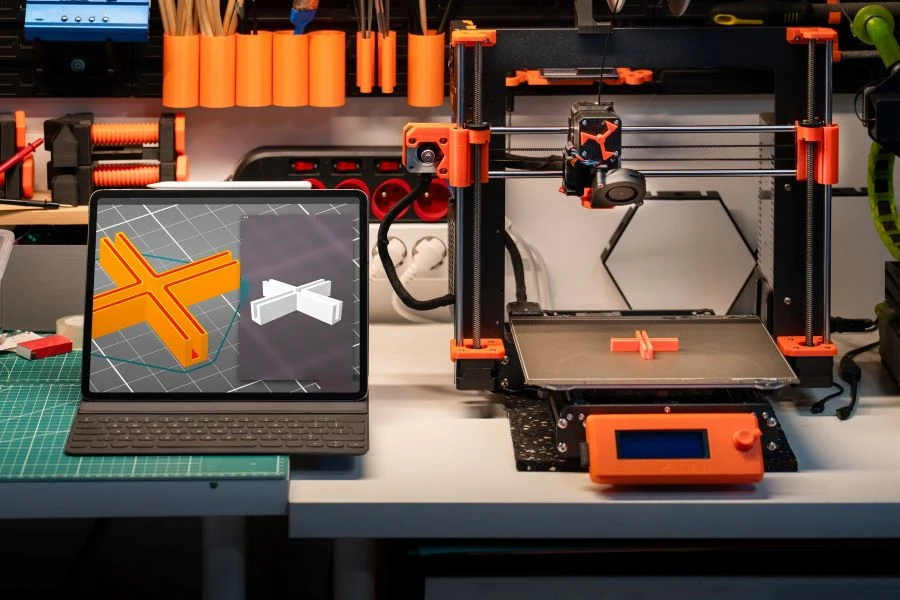

The shift towards application-driven production is reshaping the manufacturing world. It is a pivotal trend in the evolution of 3D printing technology, facilitating a change from a generalized approach to a highly specialized and efficient production method.

As more industries continue to harness the power of additive manufacturing, the customization, flexibility, and optimization inherent in application-driven production promises to reshape traditional manufacturing patterns and drive innovation across industries.

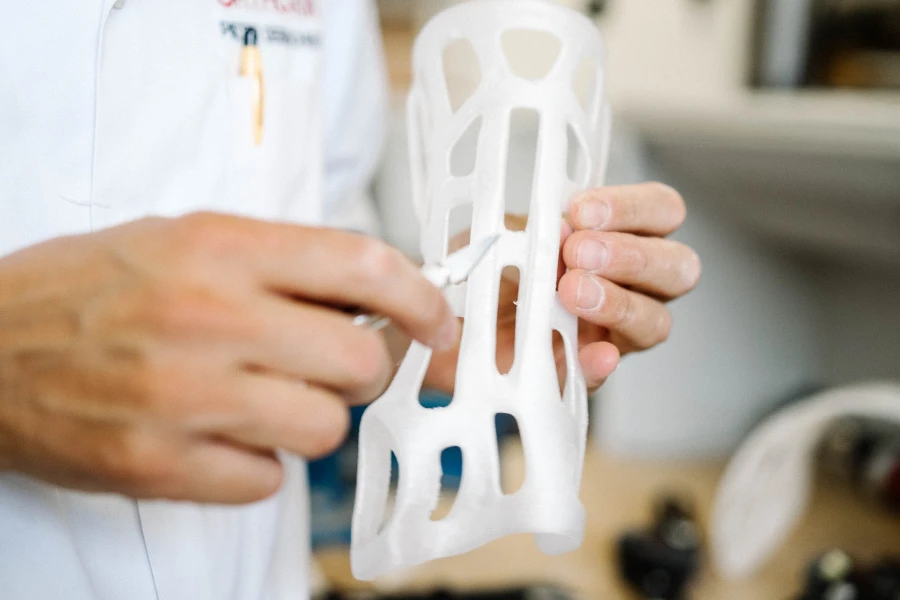

This flexibility is valuable in industries where unique designs and specifications are essential, such as healthcare for personalized medical implants.

This 3D printer trend posits a technology driven paradigm shift in how industries approach production, emphasizing the significance of custom-made solutions for specific applications.

Industrial upskill

As 3D printing becomes more integral to manufacturing processes, a skilled workforce will be needed to harness its full potential. Industrial upskilling is therefore a pivotal trend in addressing the increasing demand for qualified professionals to work in additive manufacturing with advanced 3D printers.

Industrial upskilling contributes to the substantial advancement and adoption of 3D printing technologies by nurturing expertise, encouraging adaptability, and promoting continuous learning to equip workers with the expertise they need to operate within the 3D printing landscape.

Conclusion

The 3D printer technology trend is primed for exponential growth, driven by sustainability, cost reduction, data security, material innovations, application-driven production, and industrial upskilling.

As the industry continues to evolve, stakeholders must stay up-to-date with these trends to leverage the full potential of 3D printing in reshaping the future of manufacturing. With an eye on innovation and a commitment to sustainability, 3D printing is set to revolutionize global industries, ushering in a new era of manufacturing possibilities.

For all 3D printing needs, including products, services, and trusted retailers, visit Alibaba.com.